By the way, i have just finished preparing the engine, with an holset HY35. So when it starts to spool, it still has no power.

There is a 10psi spring in the wastegate anyway so power is not an issue here.

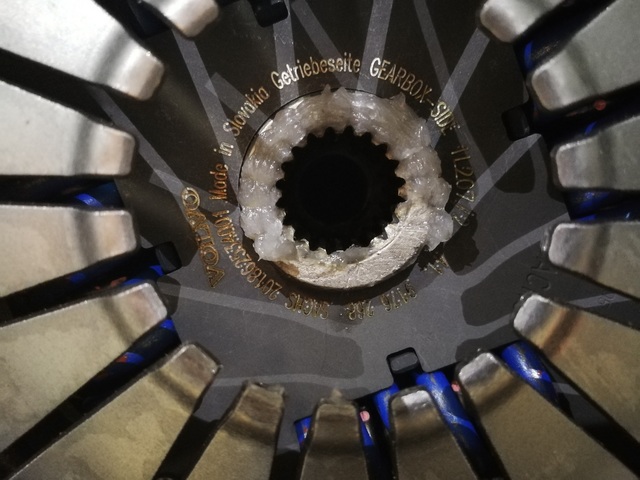

The clutch starts to slip at 3000rpm.

The clutch fork is leaning towards the front of the engine, i would say 15-20deg from straight out of the bellhousing.

Is 5.5mm of washers too much ?

There is a 10psi spring in the wastegate anyway so power is not an issue here.

The clutch starts to slip at 3000rpm.

The clutch fork is leaning towards the front of the engine, i would say 15-20deg from straight out of the bellhousing.

Is 5.5mm of washers too much ?