4-cyl

In too deep

- Joined

- Aug 23, 2008

- Location

- Seattle, WA

The 240 Turbo was a marvel of the early 80s; fuel injection, a turbocharger, high quality parts, and a strictly functional design. Any concept put into production, however, loses a bit of technology and individuality as bean counters chop away at what is “unnecessary.”

My goal with this 245T is to build it as the engineers and designers would have wanted. It should do everything that a production car should with incredible ease, but those items, both mechanical and cosmetic, that were deemed unnecessary expenditures or simply not available in 1983 (but a better solution), will be incorporated along the way.

Accomplished thus far:

Engine -

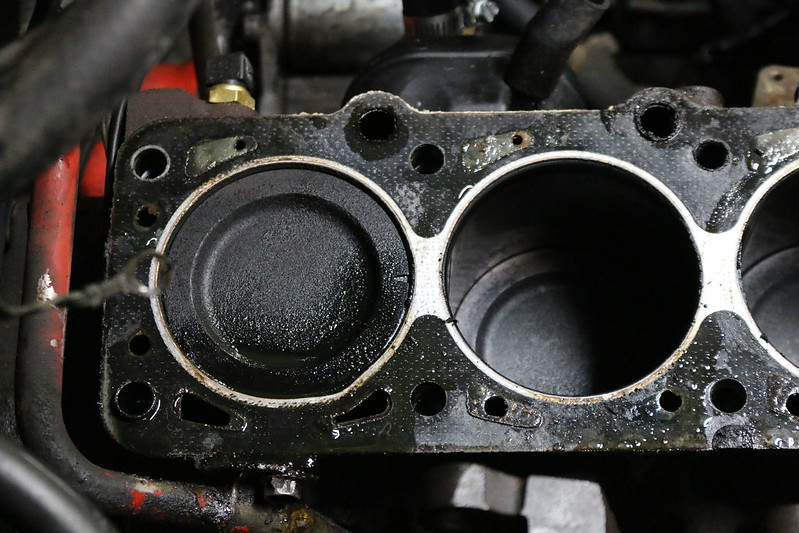

Head and valve gaskets

All front and rear oil seals

All vacuum hoses replaced w/ braided fabric line

do88 turbo inlet, intake, and intercooler hoses

New K-jet injectors

New K-jet seals

Used CPR

Fuel filter

Fuel pumps

Fuel accumulator

Throttle body cable

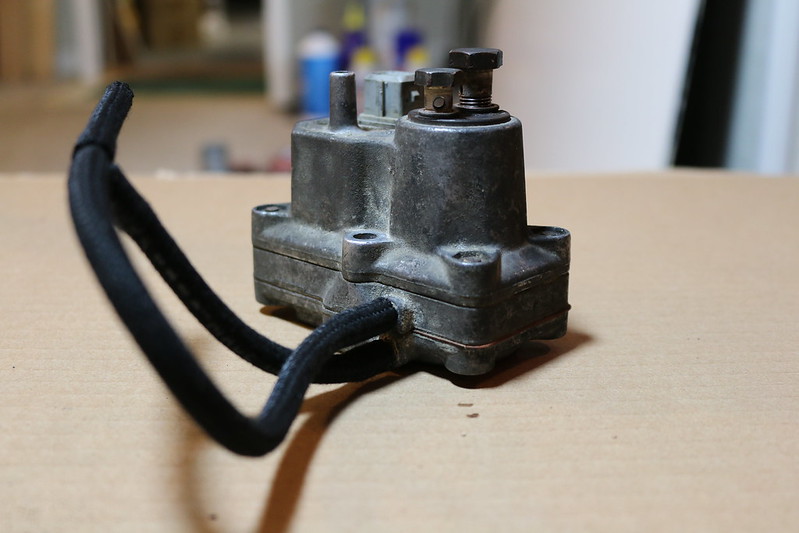

Used Idle-air Control Valve

Battery lines

PCV box

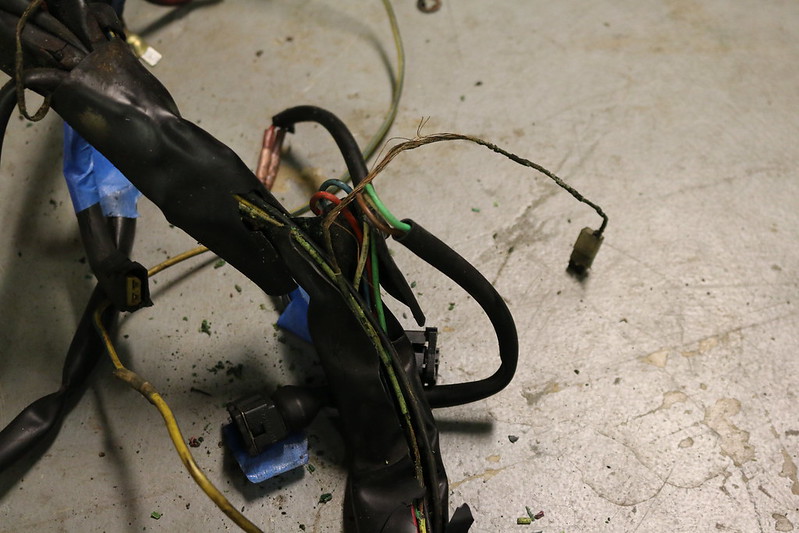

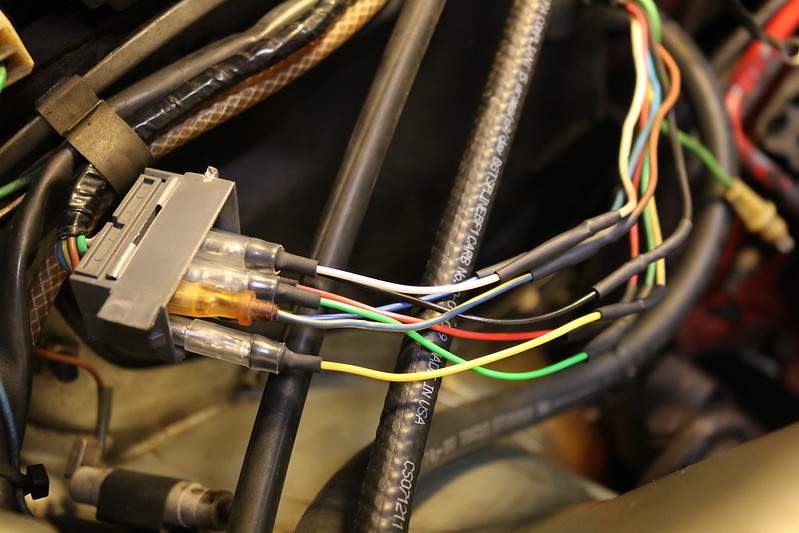

NOS replacement engine wiring harness

Rebuilt turbo-side wiring harness

Engine mounts

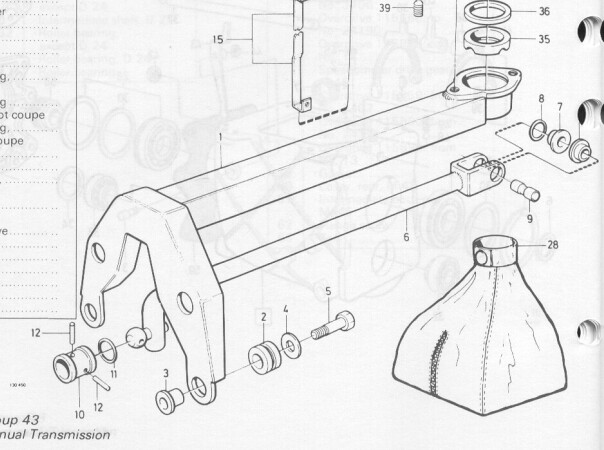

Transmission -

Resealed transmission

HD transmission mount

Suspension -

Full iPD poly set minus the TABs

Bilstein HDs

Ball joints, tie rods, top hats

Brakes -

*Have stainless lines to install

Interior -

New heater core and blower motor

Rebuilt donor black leather interior

Installed VDO boost gauge in PSI to replace clock

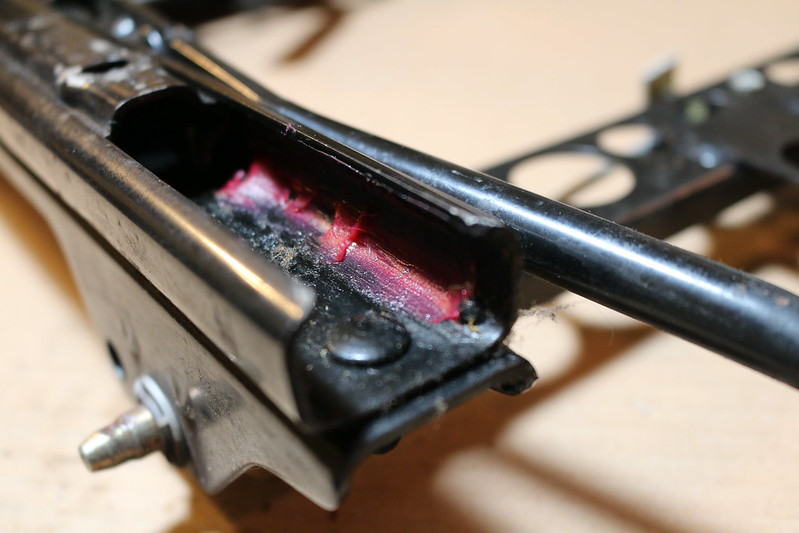

Rebuilt power window switches

Exterior -

Rack removed and plugs placed

I should mention that my mantra is “Maintenance is key.” This car will by my daily driver. Much of this build thread will focus on maintenance—getting and keeping the wagon at 100%--from K-jet stumbles to the smallest o-ring one can think of.

My goal with this 245T is to build it as the engineers and designers would have wanted. It should do everything that a production car should with incredible ease, but those items, both mechanical and cosmetic, that were deemed unnecessary expenditures or simply not available in 1983 (but a better solution), will be incorporated along the way.

Accomplished thus far:

Engine -

Head and valve gaskets

All front and rear oil seals

All vacuum hoses replaced w/ braided fabric line

do88 turbo inlet, intake, and intercooler hoses

New K-jet injectors

New K-jet seals

Used CPR

Fuel filter

Fuel pumps

Fuel accumulator

Throttle body cable

Used Idle-air Control Valve

Battery lines

PCV box

NOS replacement engine wiring harness

Rebuilt turbo-side wiring harness

Engine mounts

Transmission -

Resealed transmission

HD transmission mount

Suspension -

Full iPD poly set minus the TABs

Bilstein HDs

Ball joints, tie rods, top hats

Brakes -

*Have stainless lines to install

Interior -

New heater core and blower motor

Rebuilt donor black leather interior

Installed VDO boost gauge in PSI to replace clock

Rebuilt power window switches

Exterior -

Rack removed and plugs placed

I should mention that my mantra is “Maintenance is key.” This car will by my daily driver. Much of this build thread will focus on maintenance—getting and keeping the wagon at 100%--from K-jet stumbles to the smallest o-ring one can think of.

Last edited:

The attention to detail is amazing!! Please keep going with amazing pictures.

The attention to detail is amazing!! Please keep going with amazing pictures.