vintagewrench

Active member

- Joined

- May 9, 2016

- Location

- Paradise

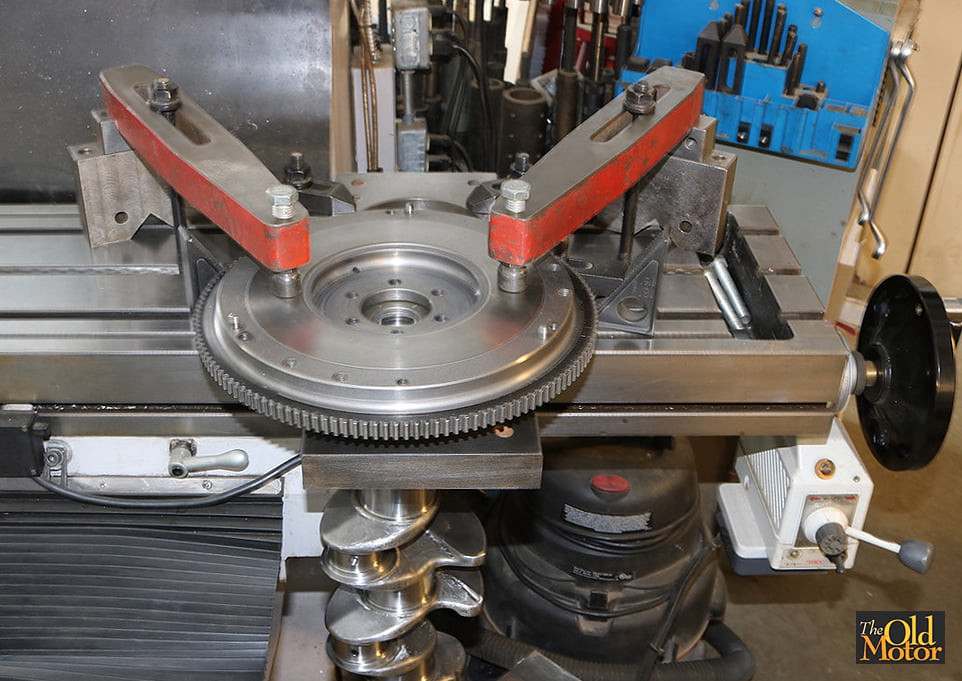

Building a pair of engines - a 67' B18 engine for road racing (most race clubs limits are only a .040" overbore) and a bored and stroked 2.2L '74 Metric B20 for a road car. Using low-mileage (less stress-cycles) 6-bolt cranks for both engines (what I have) even though an 8-bolt is better.

What is the HP/torque number at which dowel pins should be added to the crankshafts to take some of the load off of the bolts? It appears ARP no longer stocks or sells B18/20 flywheel bolts. Anyone aware of of similar high-strength 3/8"-24 bolts that can be used for this application?

The '74 B20 metric main cap bolts have covered 300K plus miles. Would like to replace the bolts with new ones or studs that can handle 200 HP for long periods of time.

Any help would be appreciated.

What is the HP/torque number at which dowel pins should be added to the crankshafts to take some of the load off of the bolts? It appears ARP no longer stocks or sells B18/20 flywheel bolts. Anyone aware of of similar high-strength 3/8"-24 bolts that can be used for this application?

The '74 B20 metric main cap bolts have covered 300K plus miles. Would like to replace the bolts with new ones or studs that can handle 200 HP for long periods of time.

Any help would be appreciated.