PNW940Pwnage

New member

- Joined

- Oct 1, 2015

- Location

- Olympia, Washington

That's a cool unit. I like seeing the old blowers on VW bugs too.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

16-valve 300 ci four actuated by rocker arms. 3 3/4 inch bore by a 6 3/4 inch stroke. - low rpm engine but it will push the car to 130 mph.

What is the idle speed on something like that? I am assuming it is slow and has a rather hefty flywheel.

What is the idle speed on something like that? I am assuming it is slow and has a rather hefty flywheel.Just a little under square.What is the idle speed on something like that? I am assuming it is slow and has a rather hefty flywheel.

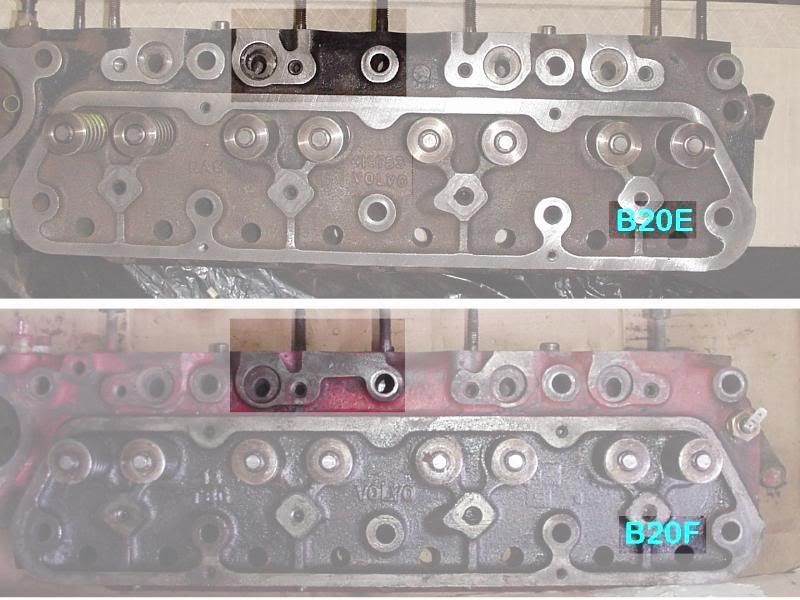

It appears that there were two different models of B20 fuel injection heads and I am looking for the one with the lowest compression ratio to use with this supercharger

One is referred to as the "E" and the other as the "F"?

What are the actual differences between the two and the compression ratios for each one?

How exactly can they be told apart?

This F head with the smaller B18 bore will lower the compression ratio below 1968 specs which will be good for the supercharger.

The E head only came on the 70 1800 and some 71 142's so it's not likely you'll bump into one.

75 was the only year for a factory black box ignition on a B20.

Or fool with the advance counterweights in the dizzy, although that's an inexact science.