Wasted spark redux

In my original version of the vaunted Buchka Bros. wasted spark, I used a non-chippable EZK, the original from my 92 940T. For the

last hurrah, now fitted with a Mitsu 19t and a real intercooler (with the resulting boost temptation) I decided to upgrade my ignition to the gold box EZK with the daughter card that allows chipping the ignition. I've long owned a gold box EZK with TLAO ignition chip for "more retard" when boosting, but decided not to risk damaging the printed circuit board with my beginner soldering skills (decision made back about 5 years ago). Since then I've raised my game in soldering electronics, and decided to proceed.

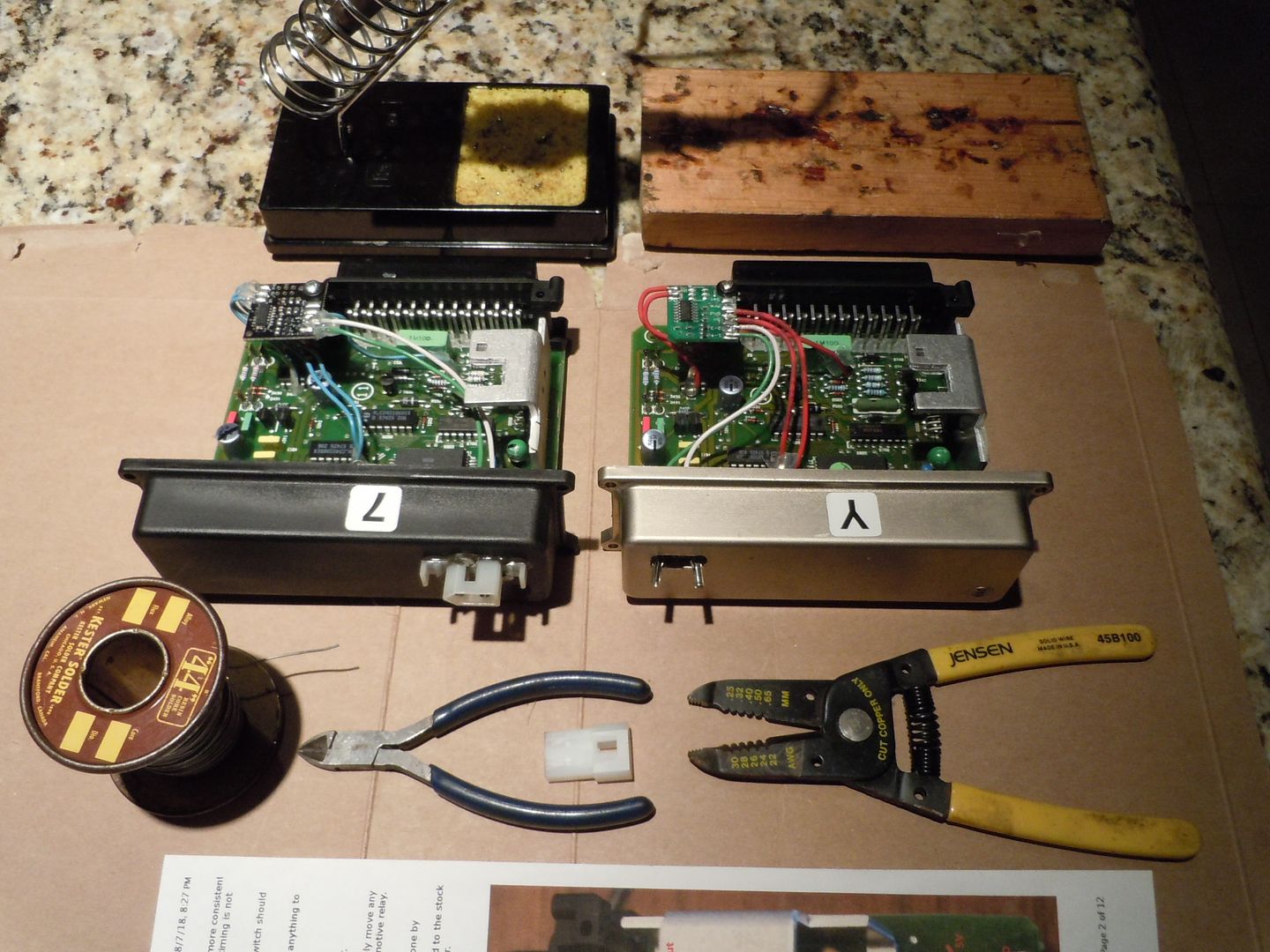

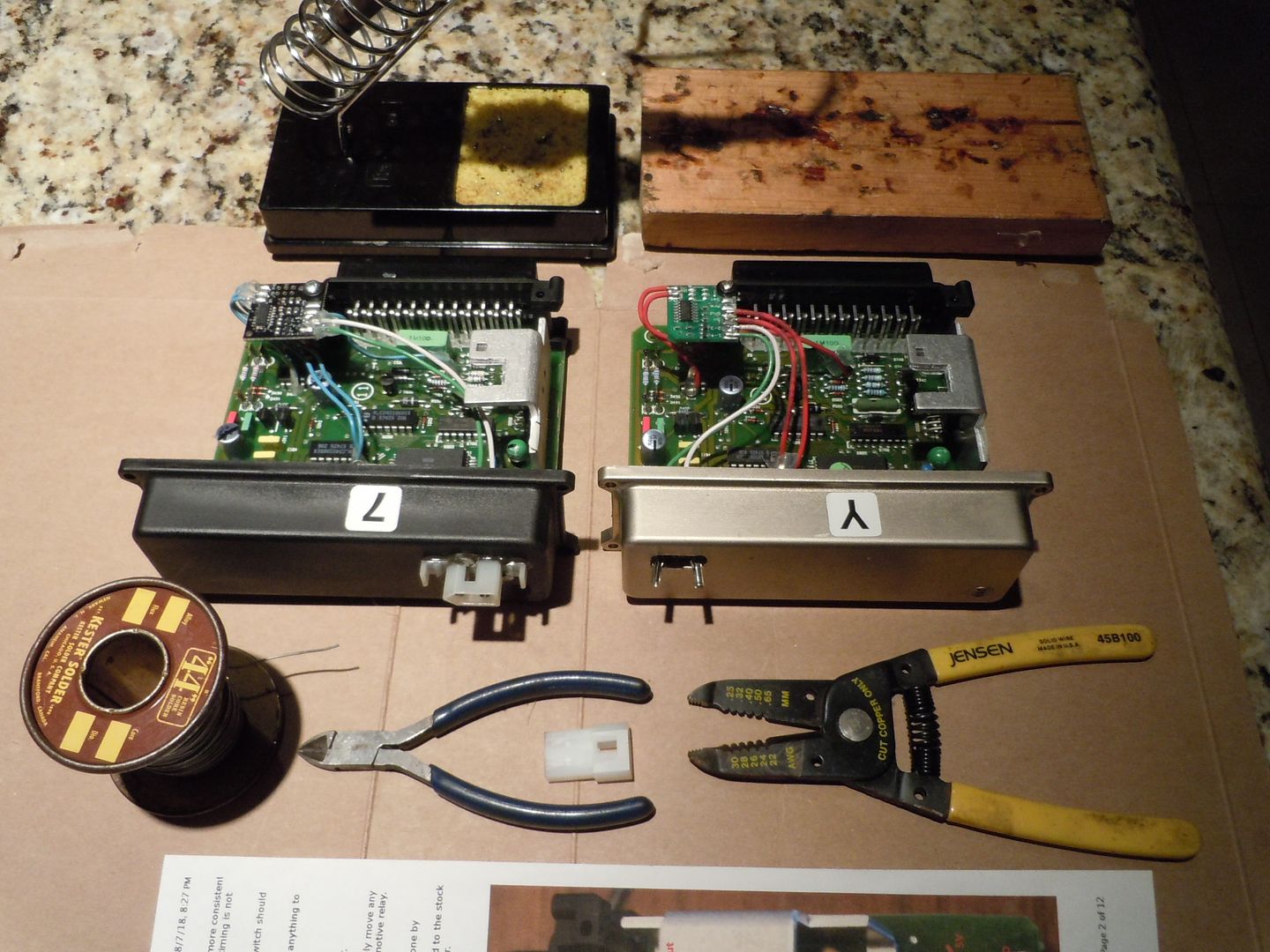

Here we see the rev.1 wasted spark alongside the redux version 2:

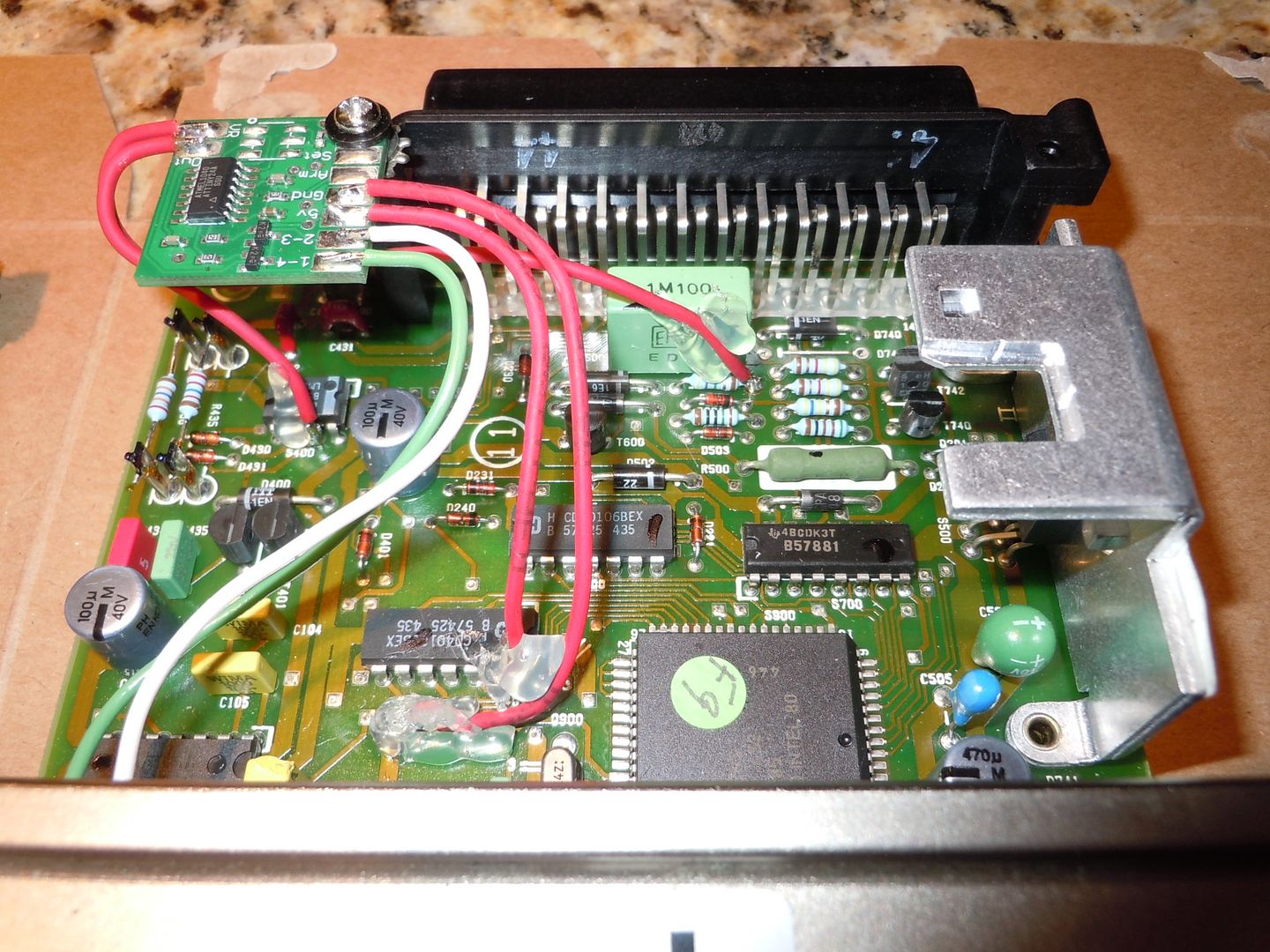

Note that the molex 2 pin connector position must flip when using a chipable EZK, compared to my rev.1 version. That presents a bit of a hassle when fitting the EZK back into the factory mount, as the molex connector & wires encounter the cabin sheet metal above the brake pedal. I've had to rotate the EZK 90* to provide clearance for the wasted spark output wires...as well as a modification to the mounting of the EZK.

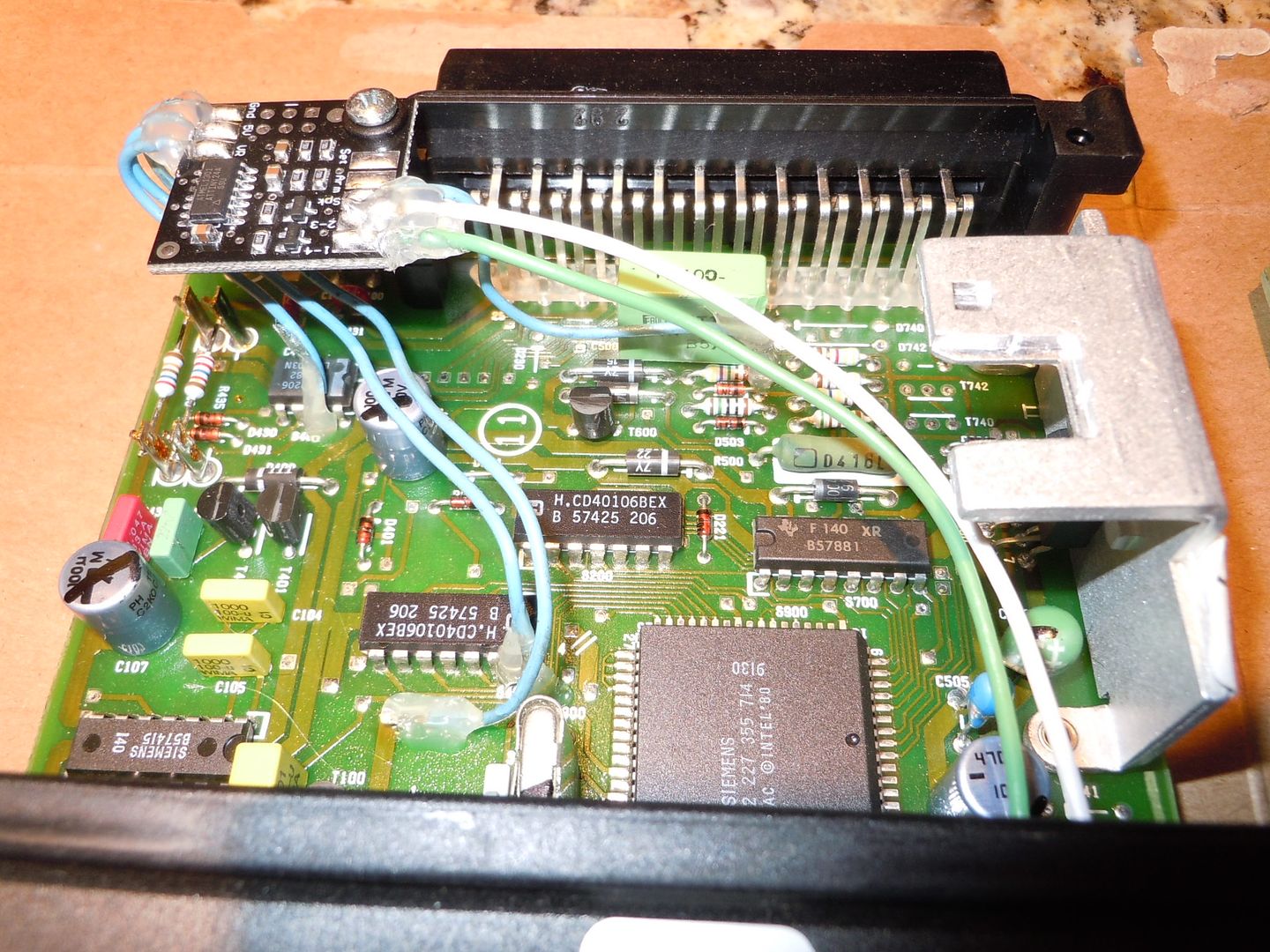

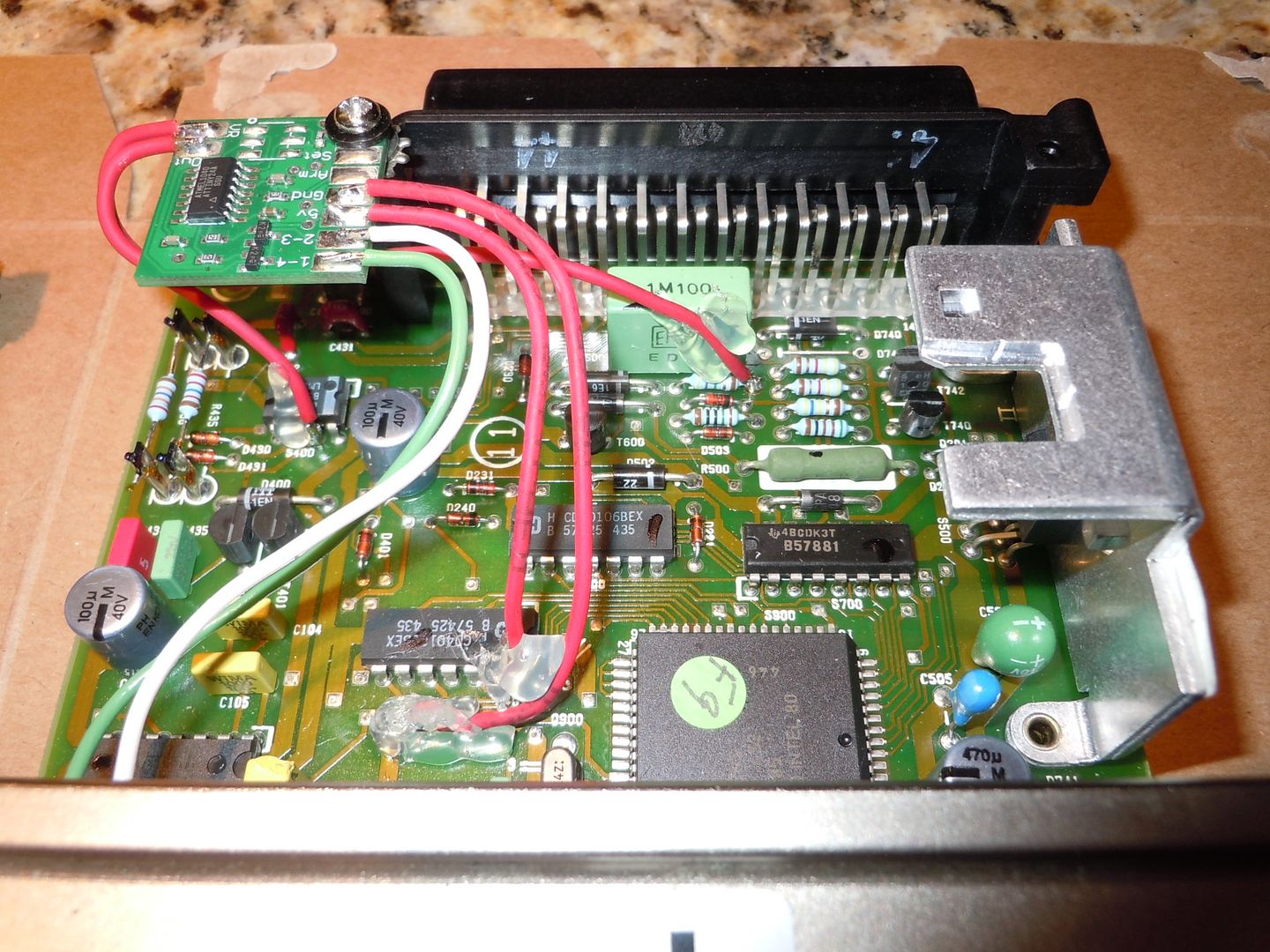

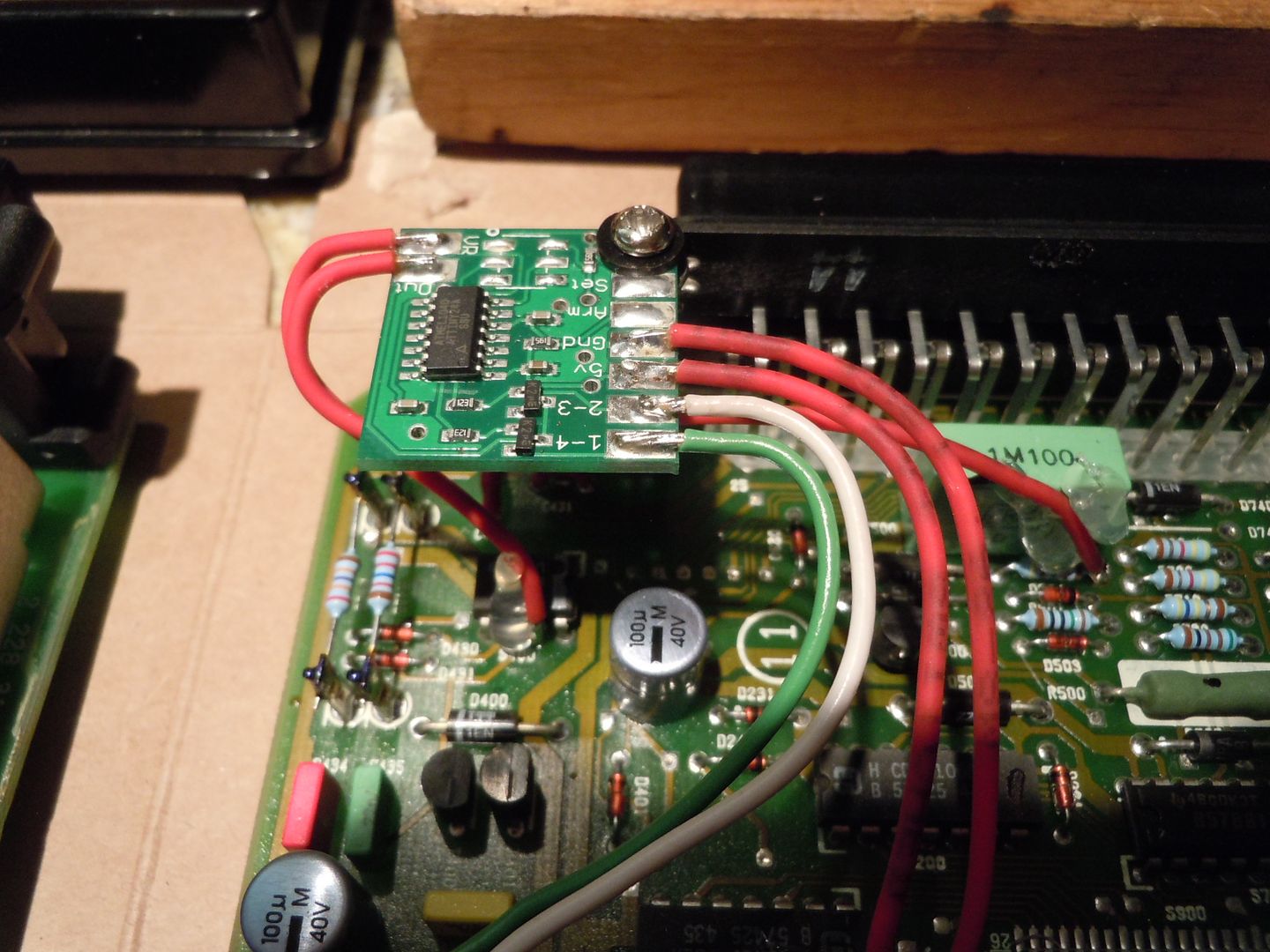

In more detail:

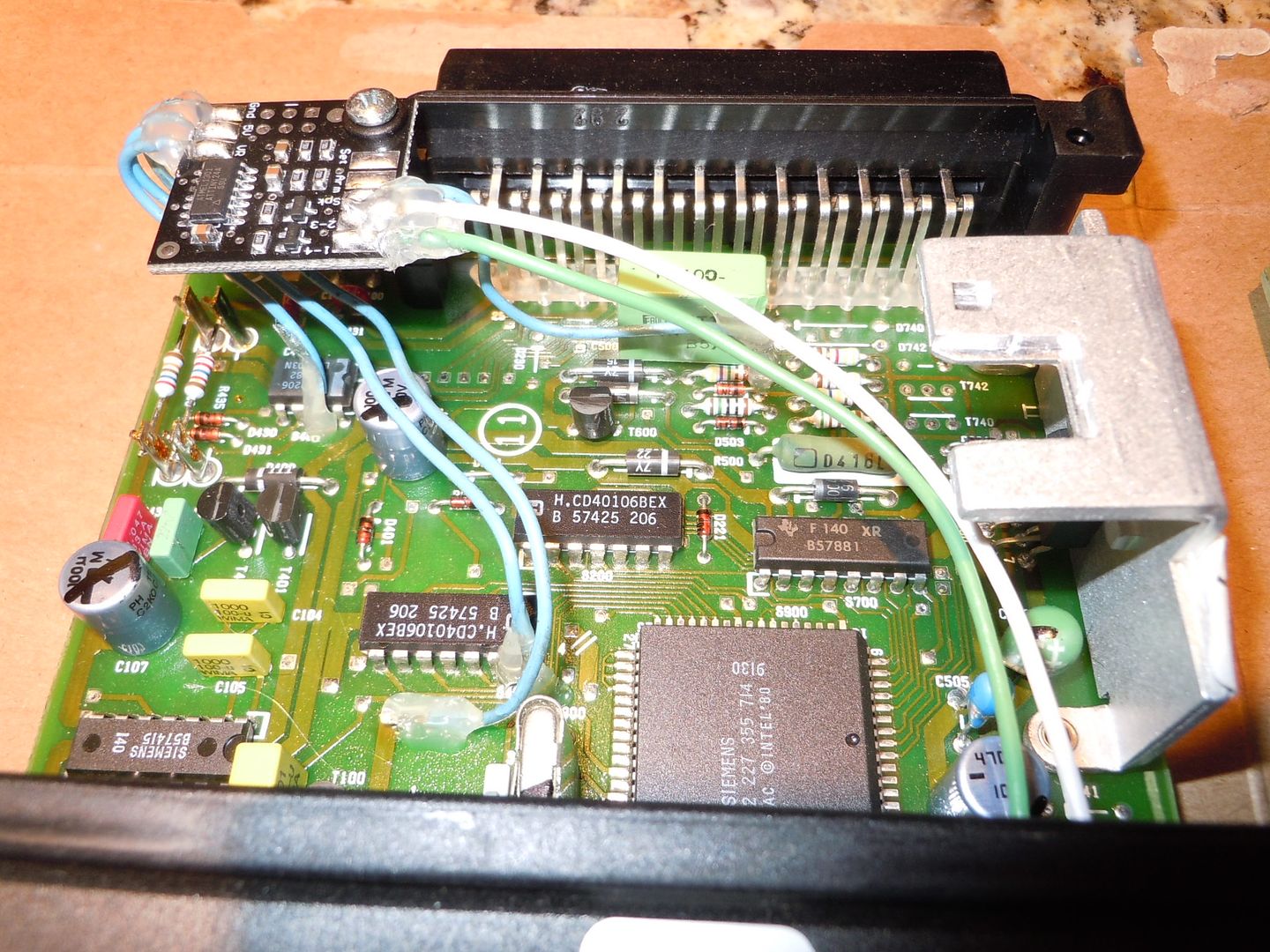

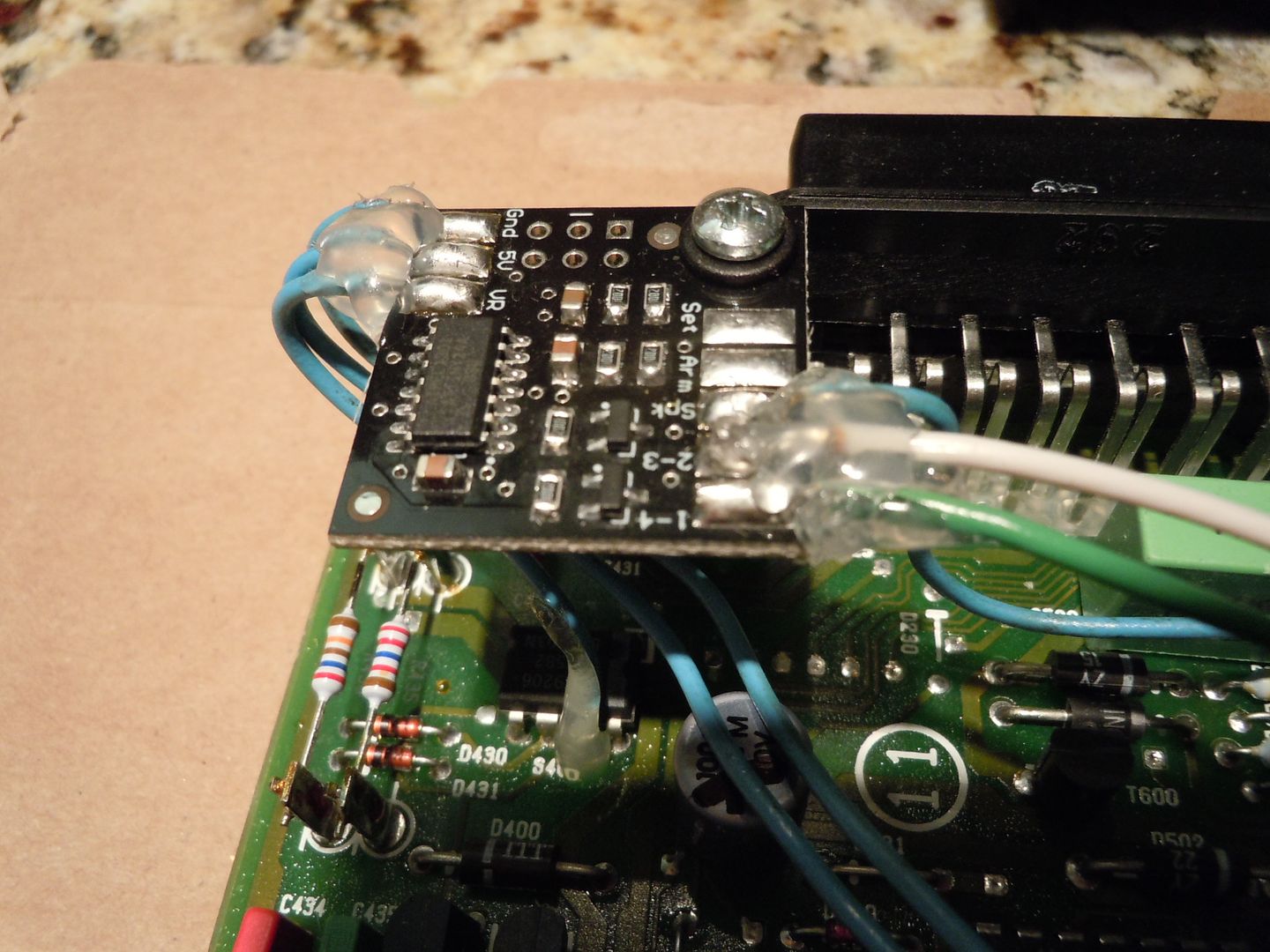

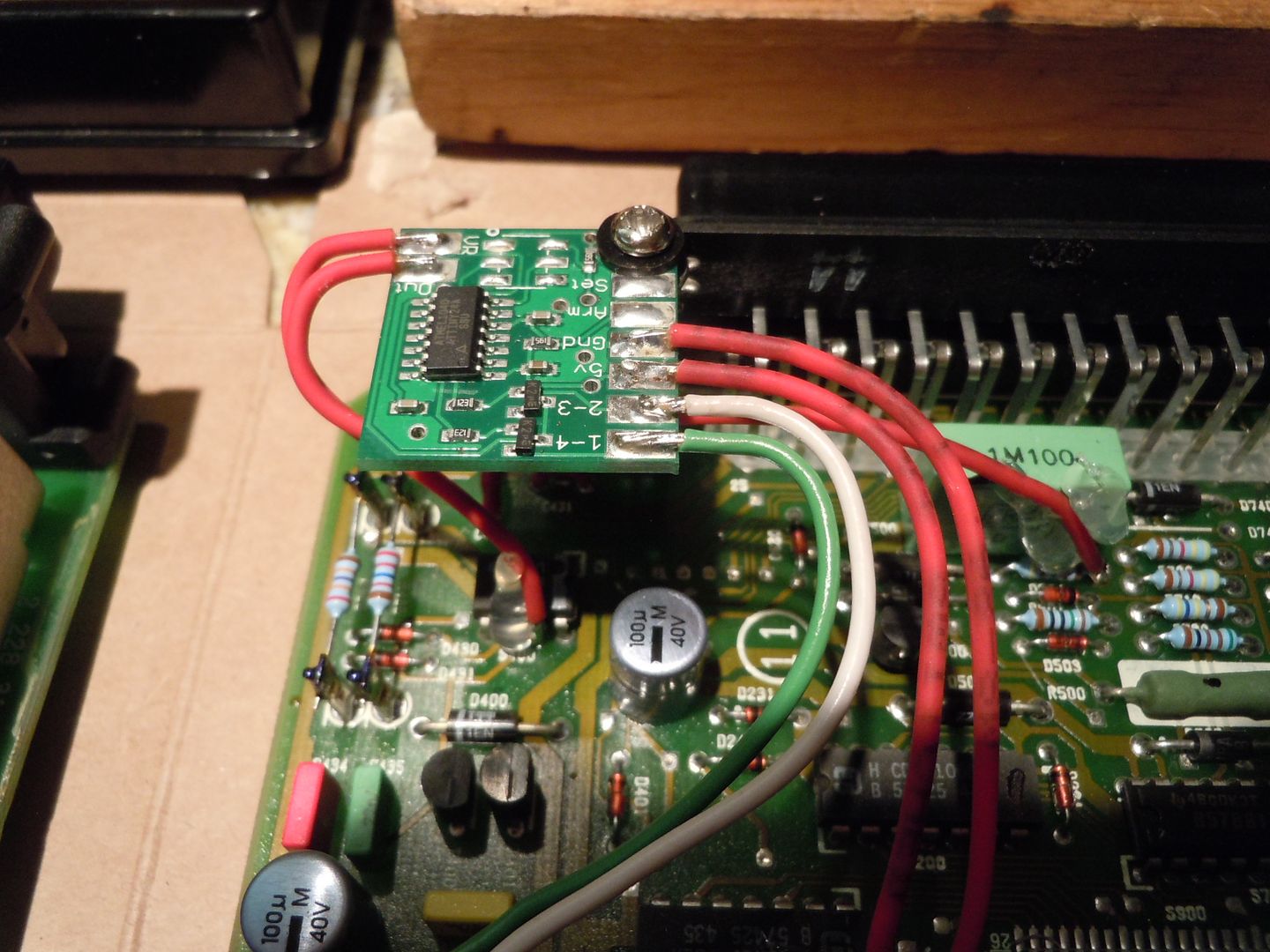

You can see the wiring routing for the 20ga control and output wires (all TTL sized; nothing here carries any current and is all 5V max). Note the black colored 2nd generation BuchkaSpark board. Compare the new (old) version:

I believe this little green WS board is from the original Buchka Bros. group buy.... it is labeled #19 on the back. I bought this from a TBer up in Alaska..... so it's pretty well traveled

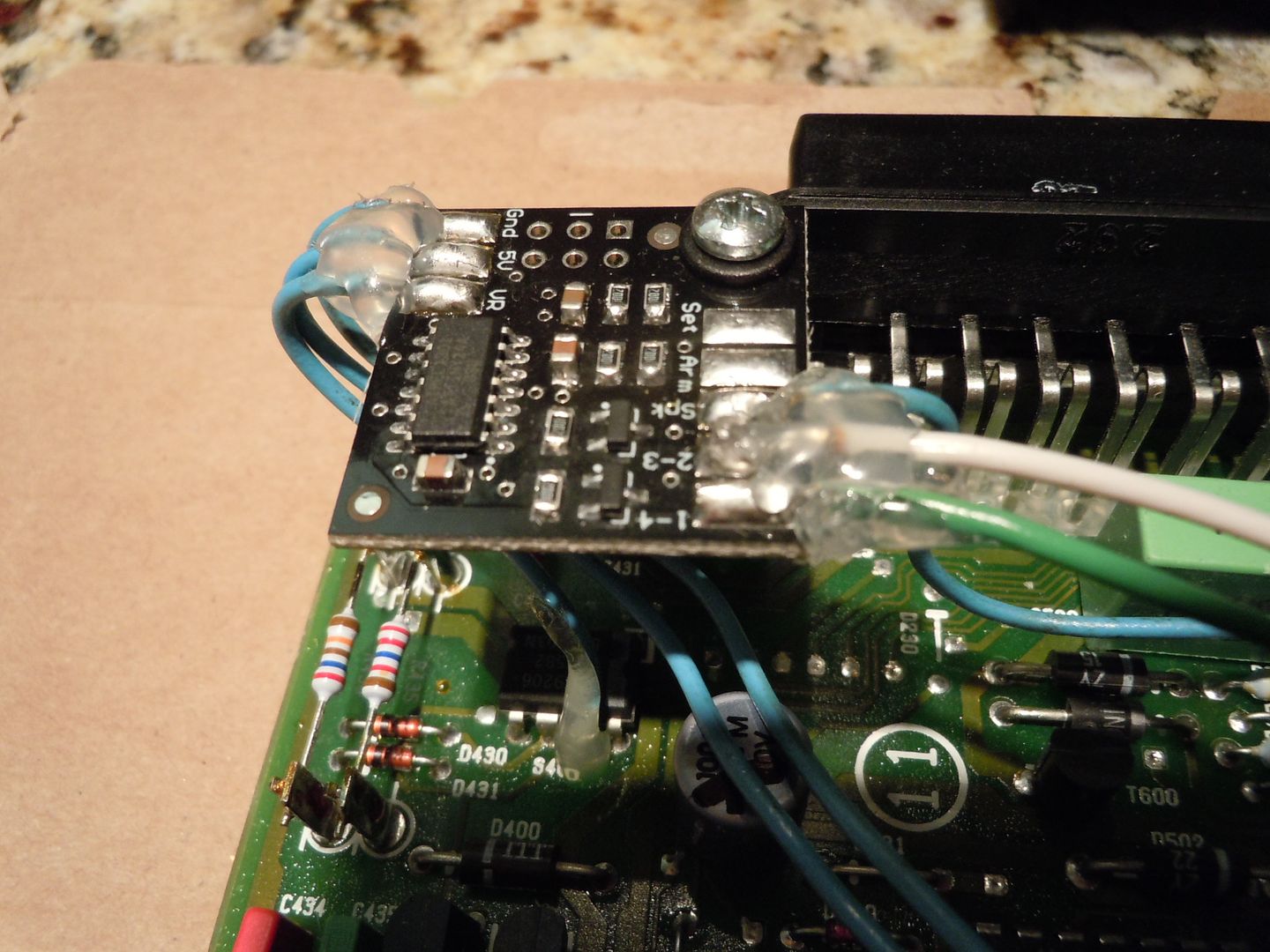

Notice the different wire landing points on the board.... the brothers revised the arrangement, I'll assume it was done for "cost down", but I can't really say. The small 20ga wiring was donated from a Megasquirt harness leftovers... and while I'm no soldering expert, as best practice I tinned both the stripped wire ends and the various landing points prior to final solder assembly. A little 25watt Weller soldering iron was all that was needed. Anyone going down this road - study some training videos on soldering before you ruin your parts... and practice on a trashed PCB before you add the ground connection; that was the tricky part of the assembly.

Some closeups comparing the boards:

Most importantly

Most importantly - the new (old version) wasted spark works with my gold box EZK and TLAO ignition chip. She fires up and purrs nicely, what with no exhaust cat back!

Next tasks - installation of my 740SE front fog lights, and the MIG work fitting and welding my stainless 409L pipes to complete the exhaust. Once these are done, the car will be dangerously close to heading for paint.