- Joined

- Oct 10, 2003

- Location

- Acworth, GA 30102

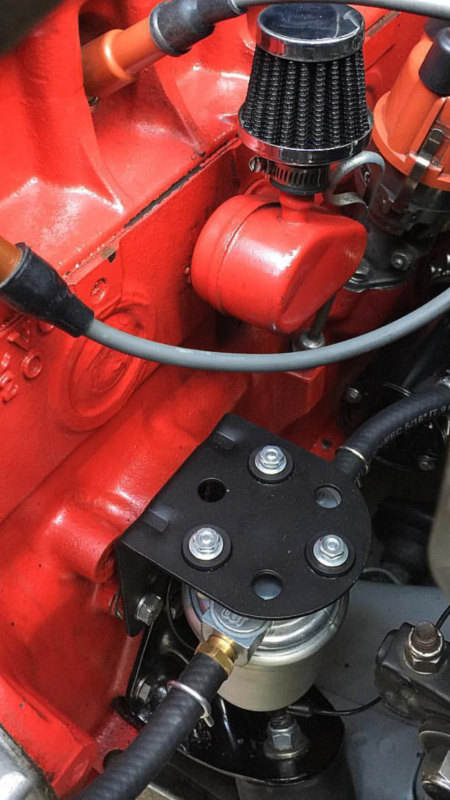

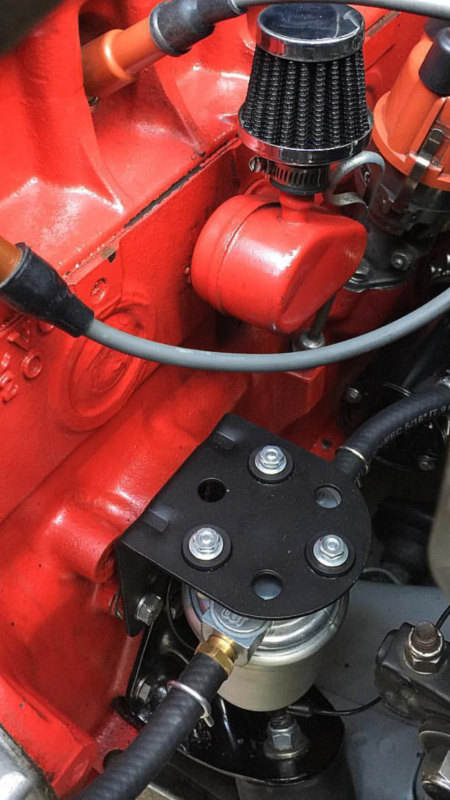

Found a guy that is running a Carter electric fuel pump with a Weber 38DGAS. He said it runs great with that pump. I like how he mounted it in the stock location. Looks to be a 6-8 psi pump. Also it looks like you could use AN fittings if you wanted

http://www.jegs.com/i/Carter/180/P4600HP/10002/-1

They also have a 4-6 psi pump that may also work.

http://www.jegs.com/i/Carter/180/P4...f8kBArxRpFZZzsdkmCS86d0nibQQyjQW1GBoCjzHw_wcB

And they also sell a kit

http://www.jegs.com/i/Carter/180/P4070K/10002/-1

http://www.jegs.com/i/Carter/180/P4600HP/10002/-1

They also have a 4-6 psi pump that may also work.

http://www.jegs.com/i/Carter/180/P4...f8kBArxRpFZZzsdkmCS86d0nibQQyjQW1GBoCjzHw_wcB

And they also sell a kit

http://www.jegs.com/i/Carter/180/P4070K/10002/-1

Last edited: