TurboDenny

Why am I here?

- Joined

- Nov 6, 2014

- Location

- Indianapolis, IN

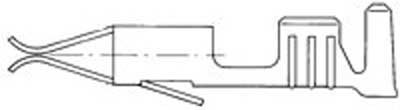

Currently in the middle of a +t on my '89 244, and I've come to the point of relocating the MAF. Does anyone know how to remove the wires from the plug itself. I'd rather not cut anything if I don't have to.