Les slight limp

New member

- Joined

- Sep 21, 2005

- Location

- clayhanger, uk

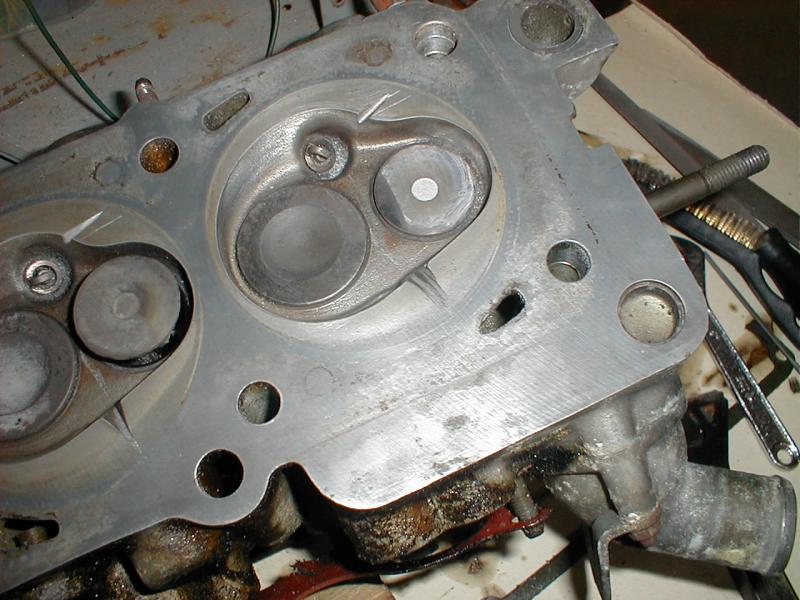

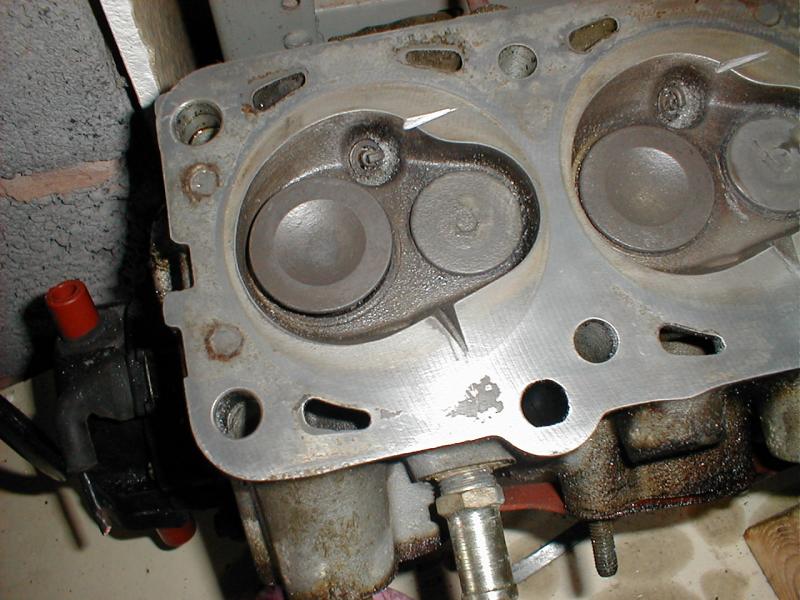

I've tried his grooves on a 530 and with 25 degrees static advance and could not get the engine to ping/knock under any load/speed combination, in my experience anything over 15 degrees produced high load low rev knock on a normal head, the engine set at 10 degrees static advance (normal) will pull happily down to 1000 revs in 5th and thats with a bad exhaust leak, i can't comment for the moment on fuel economy and high rev power because of the exhaust, i've took it up to a hundred and it seemed ok.

I tried this primarily because of the claims of better detonation control before i do my +t, i was sceptical so i tried it on a 530 and kept my my 531 stock, "just in case", i'll be modding my 531 starting this week, i'm glad i tried it on a different head first coz i didn't do a very good job of the first groove, i ended up with a medium cut triangular file which did the job great, talk about low tech, http://www.somender-singh.com/

I tried this primarily because of the claims of better detonation control before i do my +t, i was sceptical so i tried it on a 530 and kept my my 531 stock, "just in case", i'll be modding my 531 starting this week, i'm glad i tried it on a different head first coz i didn't do a very good job of the first groove, i ended up with a medium cut triangular file which did the job great, talk about low tech, http://www.somender-singh.com/