Yes, it's not an actual synchronizing ring that is welded. The ring could be called a stop ring.

This topic was once covered in a Swedish Bilsport car magazine. The original article was in Swedish, but here's a translation of that in English:

M90 with a bad third gear?

To choose a gearbox to a car is always difficult a task. Or, excuse us, to put it in other words, to brake a transmission is not too hard because modern manual trannies are not designed to be very strong. If one does not have the means to use a specially manufactured racing transmission, which in our case would've cost as much as our entire budget raised to the second power, a good choice would be to use an automatic transmission like in so many other "tough guy cars" you see on the strip. In a turbocharged car this would be even more ideal because when using one the engine will not come off boost during gear changes and it works better than a manual on take-off too. Besides, an automatic is more gentle to the rest of the driveline and to the tires too. So an automatic would be a winner choice in our situation then. But, does anyone know of a strong automatic transmission that fits a volvo directly and easily? That's right, there are no such things. So that was that.

We did not have the time to modify an amerikanski-automatic to fit our car so we decided to use Volvo's M90 transmission instead. "But the third gear breaks down on those all the time" they say. And they are right. We have a lot of M90-trannies in our garage with a broken third gear. However there is a solution to that problem which at least might save an already broken down transmission in some cases. The reason for the disaster is a too fast of a gear change from the second gear to the third. In such a case the synchronising ring (synkring?) gets an impact from the synchronising hub (synknav?) and it comes off from its place and hits the gear. Just one missed gear change might be enough for this.

Do you think that you have it in you to dismantle a transmission? Do you think that you can put it back together after dismantling? Good. Then all you need is a M90 tranny and start to work.

CAPTIONS:

Open sesame

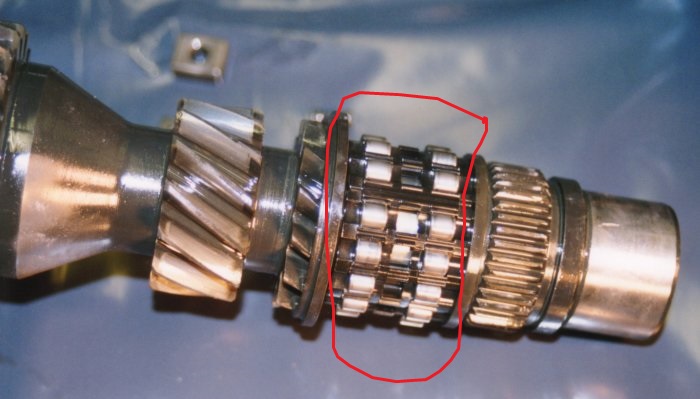

Once we have taken the transmission apart enough we concentrate on the middle axle. It is on this axle where the synchronising hub (synknav?) is situated. Fiddling around with a tranny is not as hard as it might seem to be. However you should install every part you remove to the same place and position where you took it away from. The bearing on this axle has to be removed when we start to weld to the gear because it is made of plastic and it would melt if not removed. It might seem impossible at first to remove the bearing but there actually is an opening in the bearing as shown in the picture. You just need to twist it out!

OUT OF ORDER

When looking at the gear you should see a machined groove in it. That is where the synchronising ring (synkring?) should be. The teeth in the gear underneath it are in bad shape. That has happened because of a missed gear during gear change. Synchronising ring descends too low and gets in touch with the gear and makes correct functioning impossible. Note the bearing groove above the gear. That is where the plastic bearing is supposed to be.

WELDING

Here the ring is back in its place. We shall now weld that ring to the gear from every tooth with a mig-welder. It sounds a bit rugged as a fix but it does work. Keep the old oil in the tranny, preferably fill it up. That way the welding sparks will not get attached to wrong places and besides the oil cools the parts down. And no, the oil shall not burst into flames even though welding sparks shall drop in there. Weld one of the teeth to the ring and then turn the axle 180 degrees. Weld again and now turn 90 degrees and after welding that turn again 180 degrees and weld and so on. Weld every tooth to the ring and weld with enough current to get good welds. With any luck you have just saved a broken down m90 transmission or fortified one to take the forthcoming abuse.

I'll try to find the article and the pictures in it later.