VB242

I.M. Weasel

- Joined

- Sep 21, 2011

- Location

- Driving the No Malarkey Bus

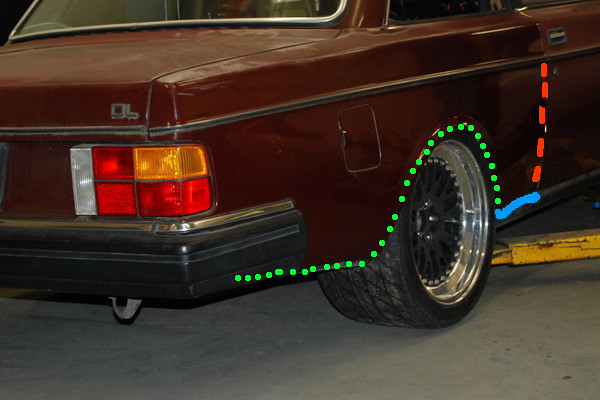

Go ahead I'm ready to take the abuse, but I want/need much more rubber on the road, like 315 section width in the rear. Because autocross. I've hacked out the inner fender, hammered it up and welded it back, so the hard part is done I can just get some wheels and hack it the edge of the fender with a cutoff wheel. These remind of the one period correct pic I saw posted on a popular science or mechanics on TB.

Are there direct fit flares out there, maybe in the motherland?

Are there direct fit flares out there, maybe in the motherland?

):

):