This is going to get ugly.

No, I don't think so, it was a legitimate question, but no sensible answers, just the usual TB hate.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

This is going to get ugly.

**** dude, genius. I feel like an idiot now..If 5 is good, surely 10 is better?

One turbo feeding a supercharger is compound charged, compounding means the second compressor compounds the boost out of the feed compressor.

I was just thinking of doing it for ****s and giggles, as long as I could produce the same power as a normal big turbo, I don't need to research compound charging, my 850 is already compound charged.

OP: the only real reason to do something like this is for a show car, like the '57 Chevy posted above, just to get attention.

As an actual, functional system it will suck. As others have mentioned each turbo would only be getting 1/5th of the available exhaust energy, once every two engine revolutions, which causes several problems. Not to mention you've got a whole lot of added weight and efficiency losses by mutliplying turbo x5. A really good modern turbo is only about 55% efficient as an overall machine...that is, you get 55% of the energy you put into it back out again as usable work. 5 small turbos are not 5 times as efficient as one large turbo, not even close. You'll have more energy losses through the turbines, bearing systems, and compressors and the engine will therefore be working much harder to produce the same power output as it would with one properly sized turbo.

Let's say you wanted to make 500 bhp (at the flywheel) from your 2.3L 5-cyl, nice round number right? That's 100hp per cylinder or 217 hp/L. You'd need something like 32 psi manifold pressure, or about 3.3 pressure ratio on a compressor map, to do so at sea level, with the system optimized and working really well. This is treating the turbo match as five individual 0.46L single-cylinder engines. The corrected mass flow rate through each compressor would end up being about 8 lb/min at 6000rpm on this engine.

Look at the compressor maps of small turbos available for sale and you'll see that none of them will be anywhere near optimal running at 8 lb/min and 3.3 PR. Taking the Garrett GT1241 as an example, it's peak efficiency is available at 8 lb/min but only up to about 2.7 pressure ratio. At 3.3 PR you'd be overspeeding the crap out of this little guy (like 300,000 rpm vs. 220,000 rpm speed limit). Overspeeding not only puts a tremendous strain on the turbo mechanically but makes it a really poor air compressor. Compressor efficiency will be terrible, intake air temps will be very high, and as a result the turbine will be working much harder, creating more backpressure and killing flow through the head (VE). As most people who have played around with turbos know, "turning up the boost" will only net you more power up to a point of diminishing returns with a particular turbo.

Taking that GT1241 down to a reasonable pressure ratio like 2.7:1 means that you'd be making about 24 psi intake manifold pressure. With a properly sized single turbo, that's about 430hp at the flywheel, and the compressor would be flowing about 36 lb/min. There are plenty of small-ish turbos that could do this all day long, without the need for the added complexity & weight of four more turbos, wastegates, charge plumbing, etc. The other advantage of a small single turbo would be that you could turn up the wick to 32 psi / 3.3 PR and make 500 flywheel hp, no problema. A GT3071R for example would be perfect for 500hp on this 2.3L.

It's true that a single small turbo will have less rotational intertia and need much less exhaust energy to spool up than a large one, and if you had a 460cc single (dirt bike for example) I'd say sure, go ahead and use a GT12 or equivalent and make something like 85hp. But multiplying that system by 5 just doesn't make much sense when the net effects will just be:

-lower peak hp potential

-increased backpressure

-increased charge air temps

-increased fuel consumption

-added weight

-5x the amount of crap to fail

vs. a properly sized single turbo system at the same power level.

Ok what about 3 cylinders feeding a 15g and the other two feeding a 12t? I'm not trolling, I just want ideas, of alternatives to something like a garrett gtx,

It was a legitimate question, tell me why it's a stupid idea.

http://www.owendevelopments.co.uk/article/19/QUAD_TURBO_KIT/

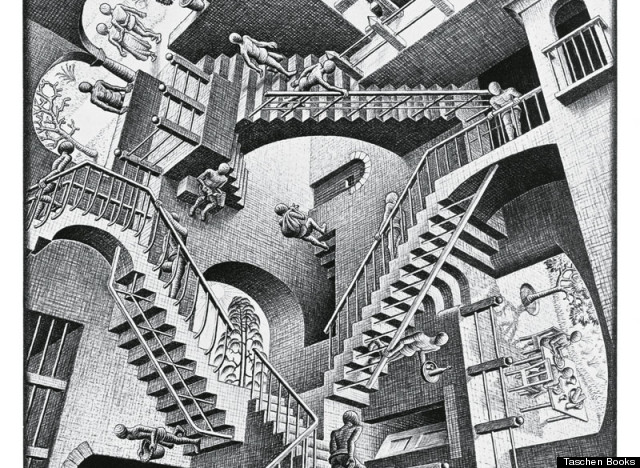

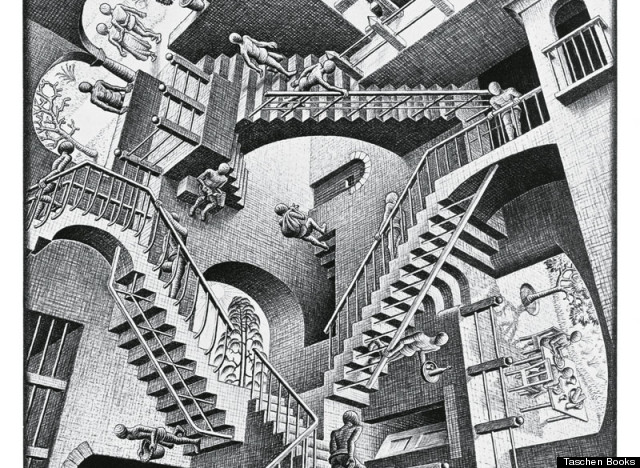

Whay about cylinder one feeding a tiny little thing into cylinder 2 a slightly larher one and progressively bigger... Screwing around with perspective,, bigger as they get farther away...

what about you do it?

now that would be some seriously funny escher-esque stuff there.

Exactly. Turbos going up pipes cone-ing out one way and cone-ing down the other..

Anything in a desparete attempt at attention..

A plumbing version of this:

But probably more like this:

And end up like this:

Brilliant

BrilliantBut probably more like this:

It was an early 90 Escort, with home made 5 point harnesses made from regular seatbelts!

It was an early 90 Escort, with home made 5 point harnesses made from regular seatbelts!

I once saw a rollcage made of pipes like that!