vintagewrench

Active member

- Joined

- May 9, 2016

- Location

- Paradise

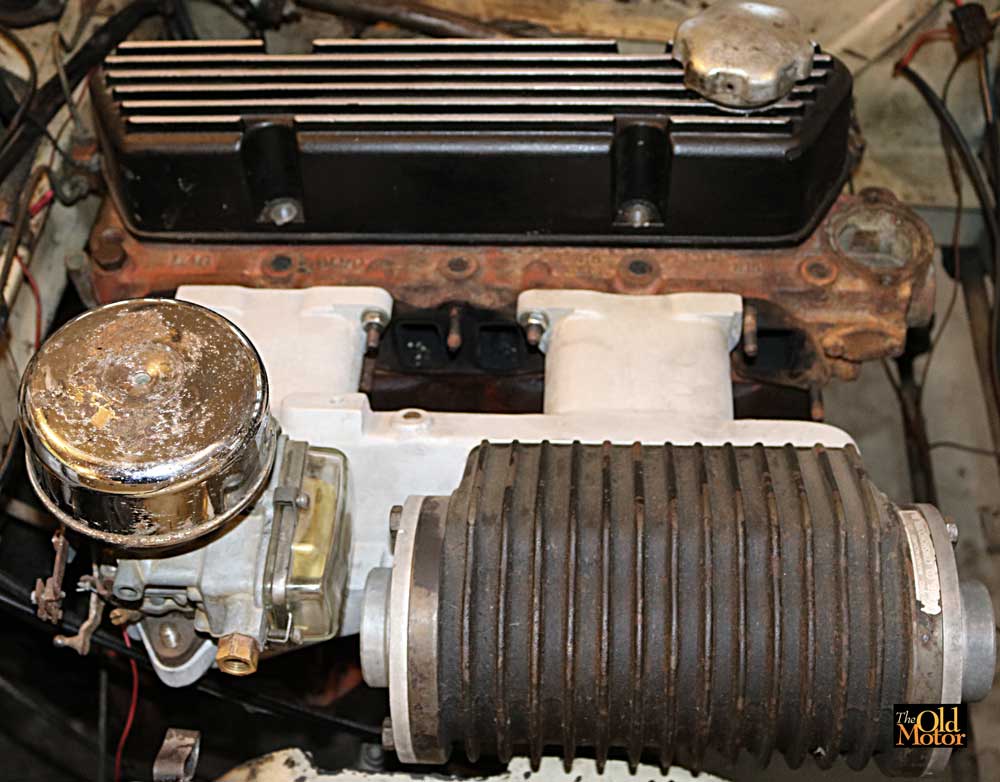

Ah - Let the games begin. The original 1968 B18 115 hp engine w/a B20 FI F head and a later M41 trans and J-Type OD comes out for a rebuild of all three.

Oh - and the problems begin as soon as the cylinder head was removed!! The engine had been rebuilt about 20K miles ago (190K total on the engine) and was over bored to the B20 standard size and everything it looks near new inside. I was hoping it had close to the original bore size because the Judson supercharger which will go on it later is sized for 1800cc engines, and the cylinder wall thickness at this size is border line for a blower installation.

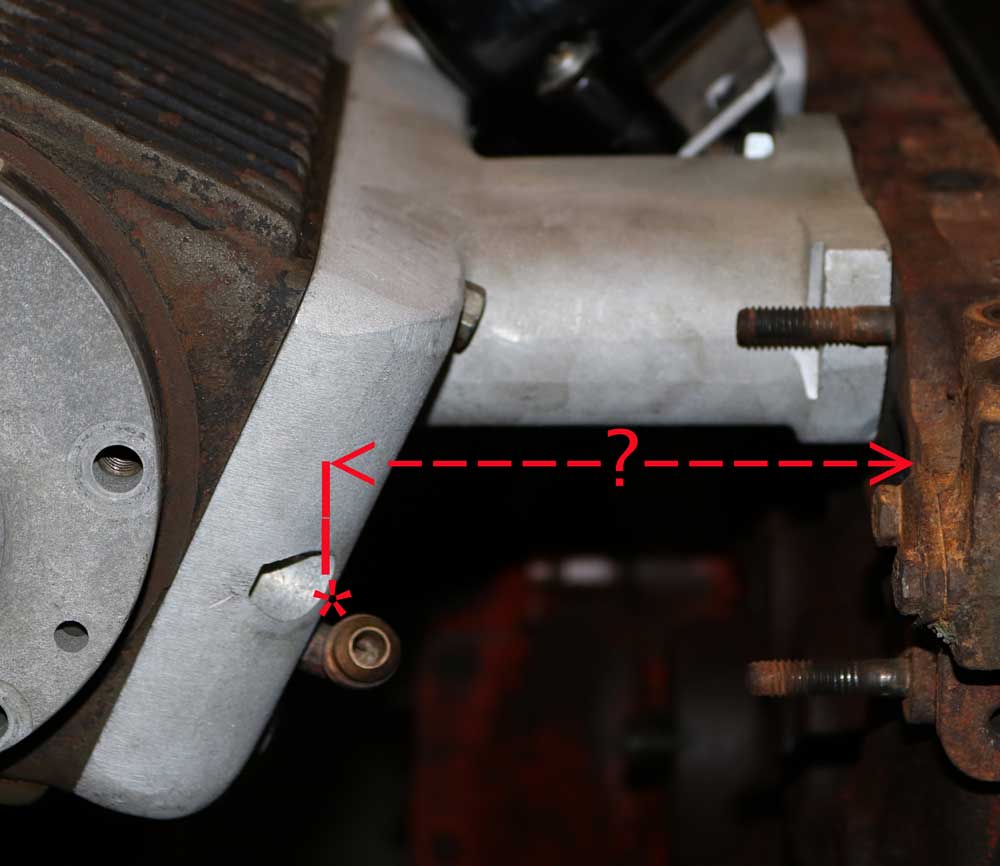

That leaves me with two choices: do a small clean up bore on the B18-B block and then sleeve it and bore it to a B18 standard bore size, or seeing as I am trying to keep this car as original as possible w/the exception of bolt on vintage speed and racing equipment, is too find another 1968 manual transmission block. This block is stamped 68 on the first of the two pads on the middle of the left hand side of the engine block, the second pad is the serial number. The first part of the number is 4968 which is cast on the block in front of both, the second number is the serial number.

Anyone out there that has such a bare block w/its original main caps in good condition that could save me from spending a lot of time w/my boring machine?

Last edited: