- Joined

- Jan 24, 2009

- Location

- KC, MO

Howdy, nicely coming along. MS3pro supports DBW now, and analog AC request, and fans, and idle up features with fans.

I might have a look into that.

I might have a look into that.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

It's CAM/TRW. There's definitely some monkey-room inside the cabin, I had my father push on the wheel gently and clearance happened, so I think I can get clearance from loosening stuff up in there and tightening it back up at a /slightly/ different angle.what type of steering rack are you running? zf or the other one?

Last week and yesterday: Finished making brake lines, mounted the proportioning valve to the inner fender, re-removed the whole shebang so the brake booster isn't in my way as I work on the clutch, and powered through soldering a large potion of wiring (joined my "standalone conversion" fuseblock to my harness, extended ECT/CLT and TAC leads, roughly placed the TAC inside the car, roughly routed the wires for AC, cruise control, instrumentation, switched power, fuel pump power, etc).

Today: spent some time not near the car, banging rocks together with my pedals - finally decided to stop futzing about with Mustang conversion master cylinders and reverse-swing pedals, take my own advice, and call up a welding-capable friends/family who can weld, to duplicate Volvorod85's hydraulic pedal conversion. Took a detour to do some therapeutic (although largely irrelevant until things like the clutch are sorted) instrument cluster work:

Well hopefully it doesn't cause issues like it does for many, it can ruin your input shaft bearings and cause shifting problems. Your only allowed .005Yup, did that. Once you've got the engine and transmission installed, it's a little late for that, lol.

Edit: Well, that's owing mainly to my hydraulic slave cylinder that requires the trans+bell to be installed together, YMMV.

Bought and installed a single-piece driveshaft... one more piece in place. With the TKO on an M46 crossmember + STSmachining adaptor + Energy poly bushing, you will realistically need a 1310-sized Yoke (of which, a Neapco N2-3-15631X is basically the only available option), and use AW70 drop spacers. 46" yoke-to-yoke, 3" tubing, and aluminum because why not.

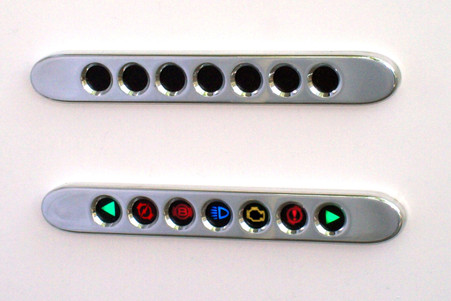

Still hacking through interior integration + instrumentation wiring... some random shots:

Fuel pump:

Instrument cluster set in place to get the wire lengths right:

Should be a pretty quick run-up to a test-fire, assuming I don't spend too much time being anal about wire lengths and making pretty Metripack connections

Already had one around as a spare for the '80, they're pretty easy to find in junkyards, and seem to last forever. Figured if it proved insufficient, it'd be a direct swap to an -044.

Actually, I'm pretty sure I got an -044 with Spoon's 242 (which I got this past weekend), might go ahead and do that shortly.

They flow less and this setup needs a constant 60psi of fuel pressure

Mine runs a 50 psi after before the rail after the fuel pressure regular. No problems