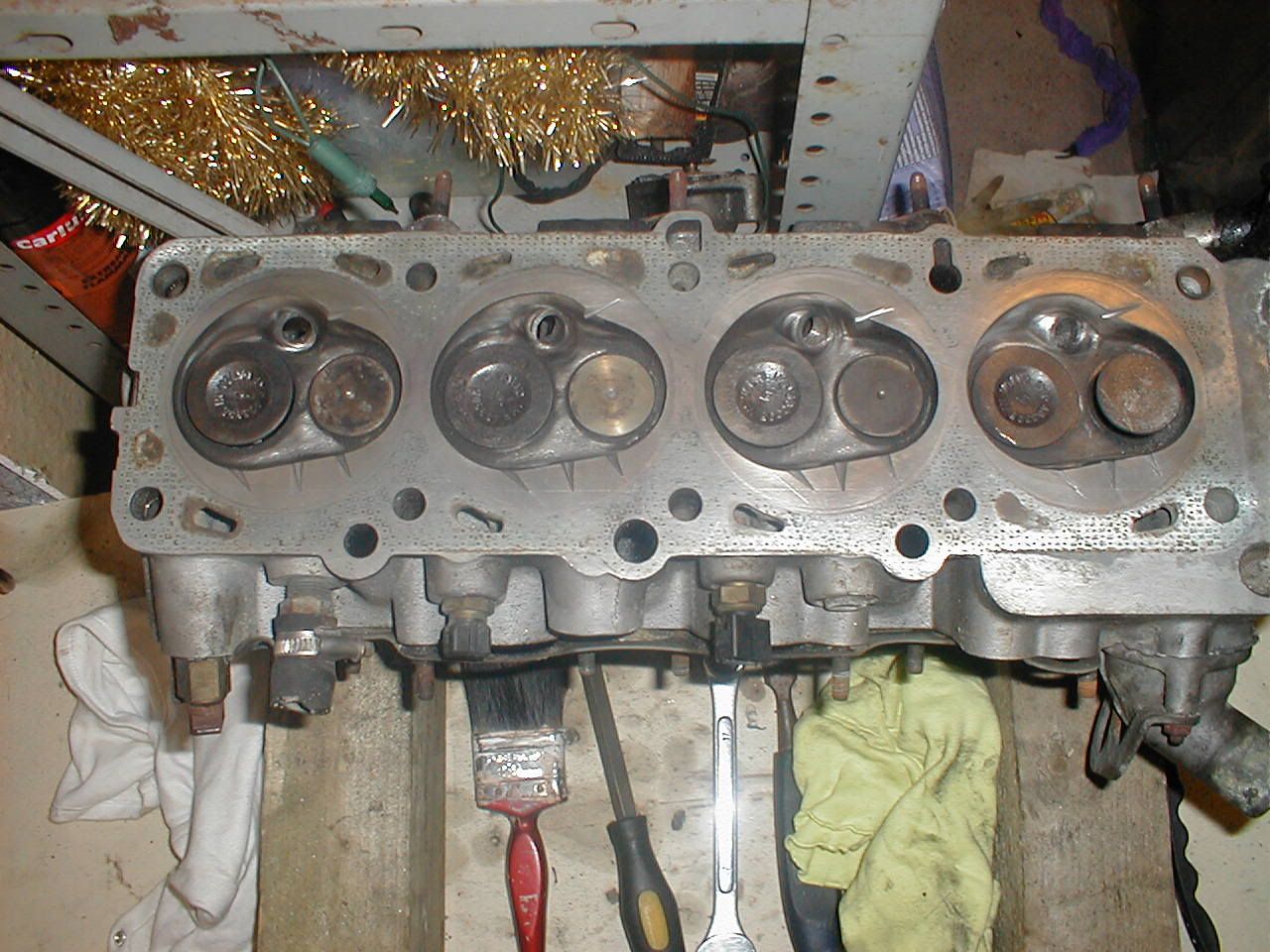

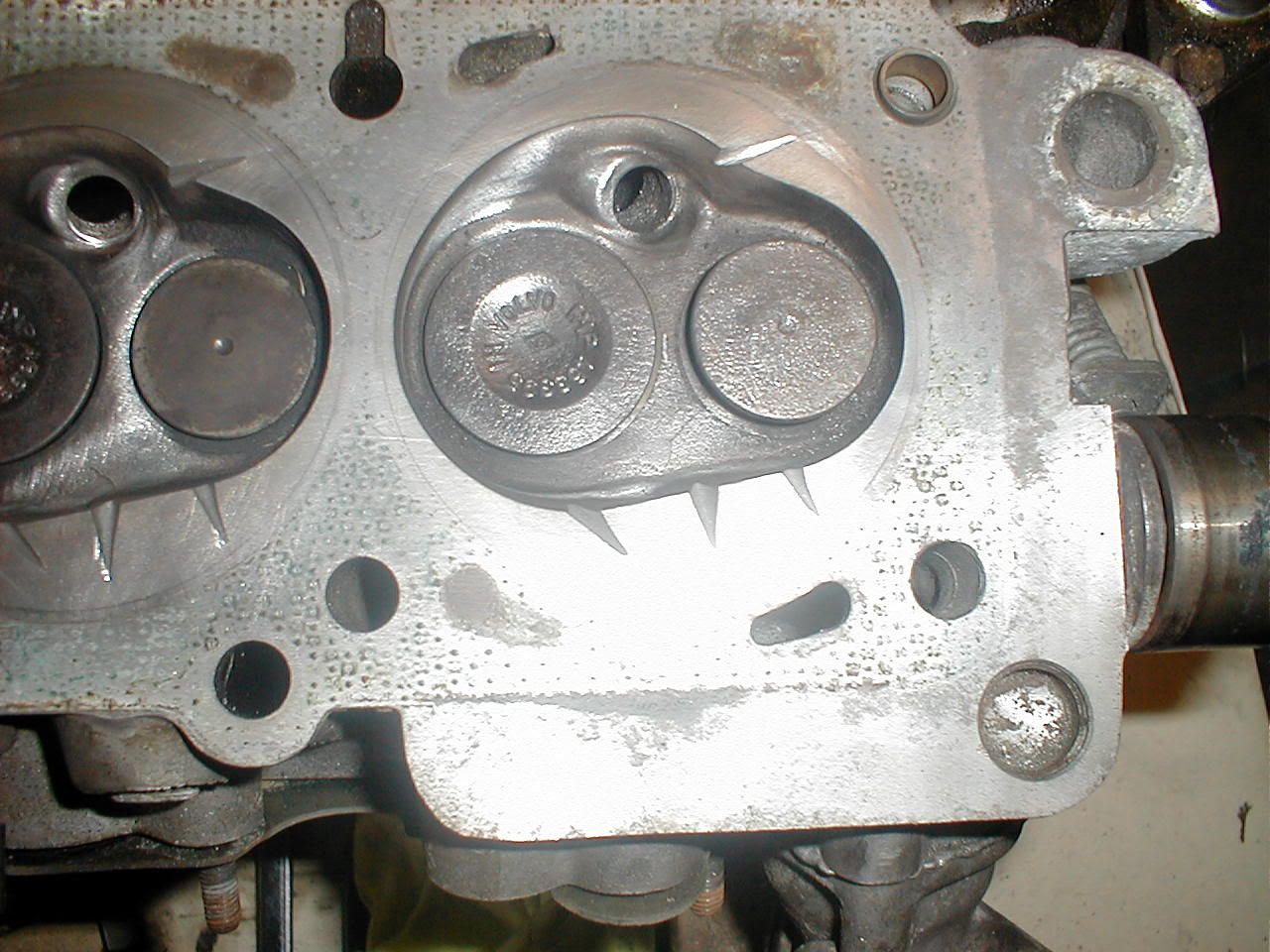

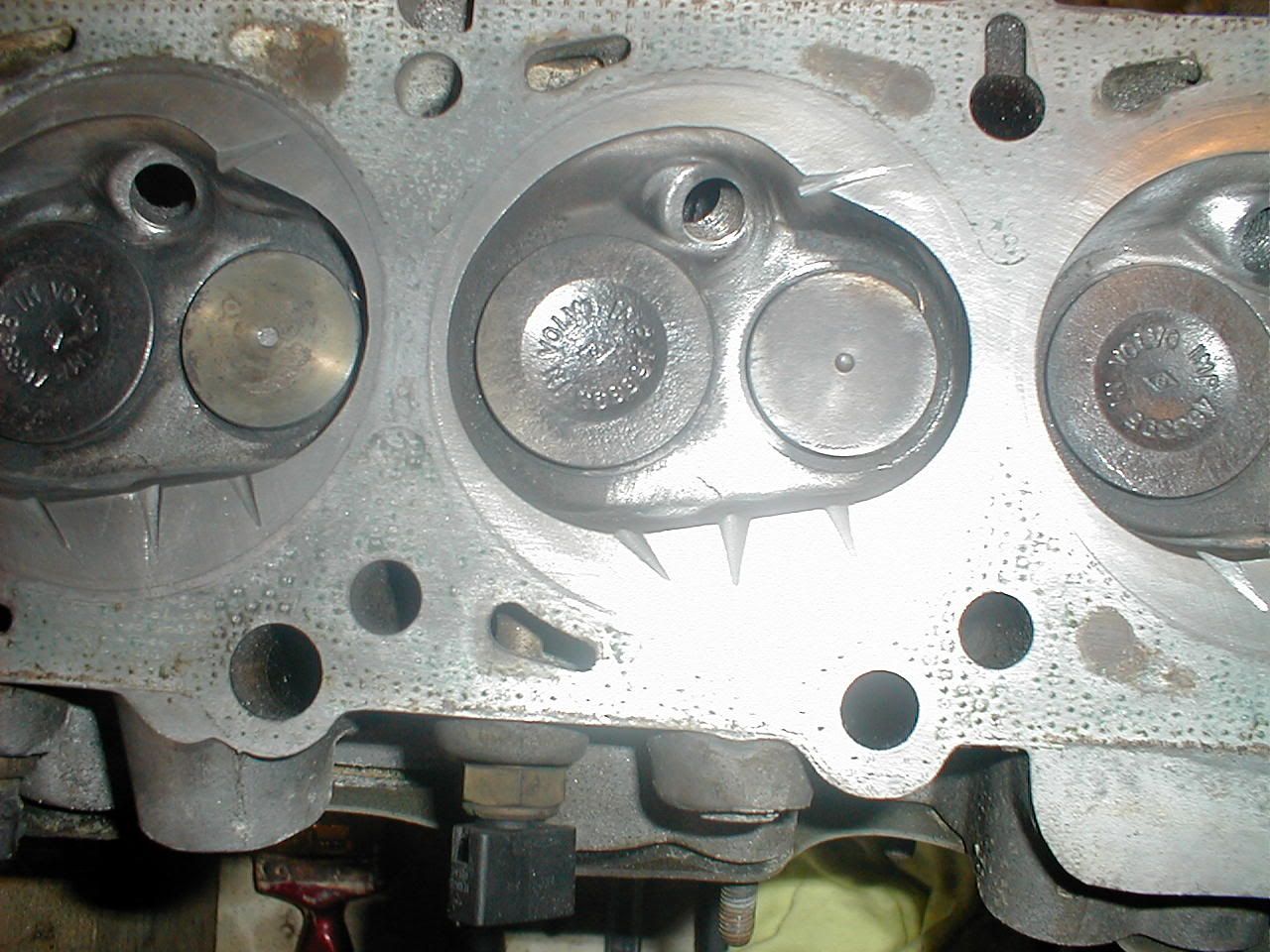

Thanks chris, did i send you the pic with my theories about mixture and flame movement and what the extra grooves are trying to achieve, it might be a bit easier for people to chime in with their thoughts if they can see what i'm trying to do.

I'm convinced somenders grooves work, there is just too much evidence now to try to say otherwise, what is still theory is to why it works and where to best place the grooves, somenders work on the central groove aimed at the spark plug has proven that location as the main one, what makes this so interesting is how we can help the main groove do its job even more efficiently.

Somenders grooves and tight squish go for the same problem in different ways, tight squish decreases squish volume in that area, burning more of the mixture and leaving less mixture to detonate, because the engine is now more efficient you can up the c/r or boost until the detonation threshold is reached again.

The grooves aim to burn the mixture more efficently and goes for a total burn approach by actually encouraging the flame "into" the squish area, that's why a deck clearance of 70 thou is recomended, that the grooves make the engine more efficient by burning more of the fuel is proven, the only way to make an existing head less prone to detonation at the same settings is to leave less unburnt fuel to detonate, thus we "know" that tight squish and the grooves work, however, much work has been done with tight squish so the threshold is pretty much known, grooves on the other hand need more data collecting to find out what the new detonation threshold is and if by a different pattern of grooves that threshold can be maximised for a given combustion chamber shape.

Many thanks to thomas for his work on volvo tight squish, i hope iv'e explained it ok in an easy to understand way, if iv'e used any terms in a wrong way i apologise, i'm not an engineering graduate, just an ordinary bloke with an interest in rwd volvo's.

)

)