-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Buchka 242 Street Car

- Thread starter Karl Buchka

- Start date

poulrais

Well-known member

- Joined

- Sep 8, 2006

- Location

- Quebec, CAN

Sander tipped me off to those earlier. I tried to order one, but the part number is invalid in the US parts system. I'll have to get one when I go back to Sweden.

Would one of these fit?

http://www.crank-scrapers.com/Volvo.html

DavoS40

Member

- Joined

- Nov 12, 2002

- Location

- Fort Collins, CO

Awesome!

Ansel+

ABG

- Joined

- Aug 3, 2009

- Location

- Portland, Oregon

- Joined

- Nov 12, 2002

random side note- the picture of Gary's 144 is in front of my shop (you can see my old t5r in the background lol)

Dauntless

The Brapmaster™

- Joined

- Jun 13, 2004

- Location

- NSW, Australia

I didn't know the B234 had different mounts.any b234 240.

i have to ask, why the b234? less work than b230 besides mounts? by the way very nice! cant wait to see more!

Having said that, it looks like a similar design might also work well for a B23 or B230 in a 240? They look like they'd control engine movement better than normal 240 mounts.

crogthomas

Active member

- Joined

- Jan 30, 2008

- Location

- UK

What's this? Secret switch?

And, what size cutter did you use on the flywheel? 10-12mm or so? Have you tried this before with a standard ECU/sensor? I'm about to do the same, but I'm not sure if it'll work.

Thanks

And, what size cutter did you use on the flywheel? 10-12mm or so? Have you tried this before with a standard ECU/sensor? I'm about to do the same, but I'm not sure if it'll work.

Thanks

Karl Buchka

Active member

- Joined

- Mar 25, 2007

- Location

- Los Angeles

What's this? Secret switch?

And, what size cutter did you use on the flywheel? 10-12mm or so? Have you tried this before with a standard ECU/sensor? I'm about to do the same, but I'm not sure if it'll work.

Thanks

That's for adjusting boost by turning the original vent control knob. Here's a thread I posted earlier: http://forums.turbobricks.com/showthread.php?t=284588

I think I used a 3/8" endmill. I haven't turned the engine over yet, but 77volvo245 has been selling largely identical flywheels for a while and they seem to work great: http://forums.turbobricks.com/showthread.php?t=251267

propav8r

F*ck Edgar

- Joined

- Jan 17, 2010

- Location

- Franklin, NC

I didn't know the B234 had different mounts.

Having said that, it looks like a similar design might also work well for a B23 or B230 in a 240? They look like they'd control engine movement better than normal 240 mounts.

I asked him about it the other day...I think I'm gonna try and whip some up for my car, and if they're successful, I'll see about doing a GB of some sort. I've got access to a 3 axis CNC, the ability to draw basic stuff in CAD and a buddy who's an excellent welder.

Now I just need a couple old torque rods...

CAPT_BLOTTO

#Crush It

- Joined

- Jul 19, 2005

- Location

- Kansas City

Am I allowed to comment in this thread?

Dauntless

The Brapmaster™

- Joined

- Jun 13, 2004

- Location

- NSW, Australia

That would be excellent. I'm sure many of us would like a bolt on solution which controls engine movement properly while also lasting a long time.I asked him about it the other day...I think I'm gonna try and whip some up for my car, and if they're successful, I'll see about doing a GB of some sort. I've got access to a 3 axis CNC, the ability to draw basic stuff in CAD and a buddy who's an excellent welder.

Now I just need a couple old torque rods...

I'd definitely buy a set from the first batch.

Karl Buchka

Active member

- Joined

- Mar 25, 2007

- Location

- Los Angeles

Downpipe got some love tonight. Welded up a couple of pinholes, added an O2 bung, and sanded the flange flat.

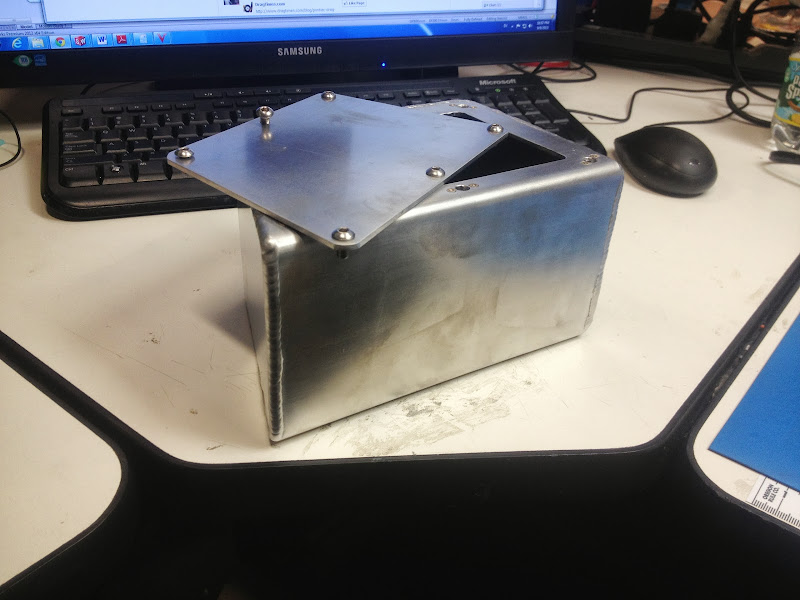

Alex made this nice aluminum catch can that'll go next to the wiper motor.

I just made some -10 weld fittings for it.

-10 to -10 coupler from McMaster ($7). Chop it in half and dress the ends. Took me about 10 minutes to do these four. Cheaper than paying $10 a piece for weld fittings.

Alex made this nice aluminum catch can that'll go next to the wiper motor.

I just made some -10 weld fittings for it.

-10 to -10 coupler from McMaster ($7). Chop it in half and dress the ends. Took me about 10 minutes to do these four. Cheaper than paying $10 a piece for weld fittings.

Last edited:

crogthomas

Active member

- Joined

- Jan 30, 2008

- Location

- UK

fly

Thanks, I'd not seen that before. What clutch are you going to use? I'm going to fit a 850R clutch connecting to a M90 box.

I think I used a 3/8" endmill. I haven't turned the engine over yet, but 77volvo245 has been selling largely identical flywheels for a while and they seem to work great: http://forums.turbobricks.com/showthread.php?t=251267

Thanks, I'd not seen that before. What clutch are you going to use? I'm going to fit a 850R clutch connecting to a M90 box.

crogthomas

Active member

- Joined

- Jan 30, 2008

- Location

- UK

-10 to -10 coupler from McMaster ($7). Chop it in half and dress the ends. Took me about 10 minutes to do these four. Cheaper than paying $10 a piece for weld fittings.

Good idea. These are the sort of details I love. Keep them coming.

Karl Buchka

Active member

- Joined

- Mar 25, 2007

- Location

- Los Angeles

Welded a bracket to the compressor housing to hold the wastegate actuator. The bracket has M6 rivnuts in it.

I have no idea where this actuator came from, but I tested it and it cracks at 4psi and is wide open at 12psi.

It's a mystery pressure plate with an unsprung 4-puck disc.

I have no idea where this actuator came from, but I tested it and it cracks at 4psi and is wide open at 12psi.

Thanks, I'd not seen that before. What clutch are you going to use? I'm going to fit a 850R clutch connecting to a M90 box.

It's a mystery pressure plate with an unsprung 4-puck disc.

Dauntless

The Brapmaster™

- Joined

- Jun 13, 2004

- Location

- NSW, Australia

Nice work. I like this project.

- Joined

- Sep 18, 2002

-10 to -10 coupler from McMaster ($7). Chop it in half and dress the ends. Took me about 10 minutes to do these four. Cheaper than paying $10 a piece for weld fittings.

Be careful doing that for anything that will see hard use- a random Mcmaster thing is probably 6061 but many AN fittings are not made from alloy that's considered weldable (2024 is common).