carbonmike

New member

- Joined

- Mar 6, 2014

- Location

- Seattle

I have a junk cracked EFI head that I got for practice porting. Free to anyone who will pay for shipping.

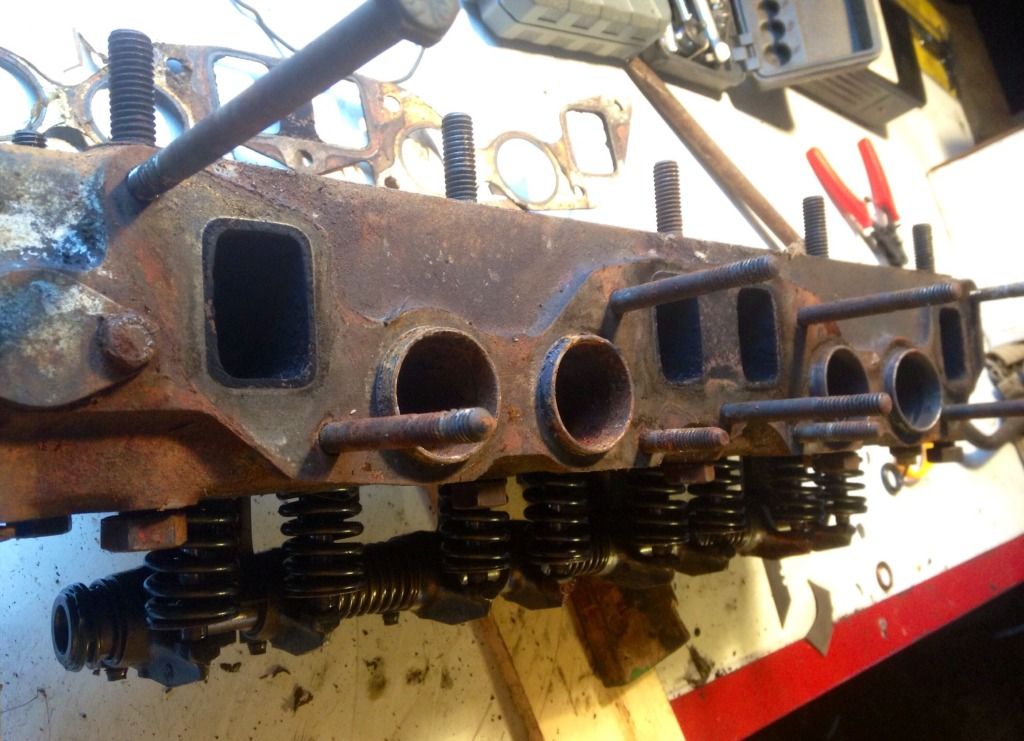

A few beers gave me the confidence to just dive into my freshly machined head. I just used a dremel, going was slow, but on purpose. Closely studied every port picture Canuck ever posted. Very happy with the results.

A few beers gave me the confidence to just dive into my freshly machined head. I just used a dremel, going was slow, but on purpose. Closely studied every port picture Canuck ever posted. Very happy with the results.