I'm B Aa Ccc Kkkk ! ! !

. . . and need help.

I had to put this thing down and forget about it for awhile.

With a new tank, new pumps, new filter, new fuel distributor and new fuel I thought this thing was going to be easy.

Previously I had verified that compression was good on one cylinder. Meter on my 45+ year old compression tester read about 160 psi.

Today I checked compression on all cylinders, warm engine, with a new compression tester:

1 -170, 2 -172, 3 -167, 4 -162, 5 -168, 6 -162

Boy, that looked good, well above specs and within 10%.

The old plugs were what I would call ‘text book tan’, what you would expect to see associated with a well running engine in a training manual. I installed new plugs along with resolving all the fuel issues and had not had them out since.

Today, for whatever reason, the left bank appeared as you might expect but the right bank was ‘as new’ without showing any signs of combustion. That was strange.

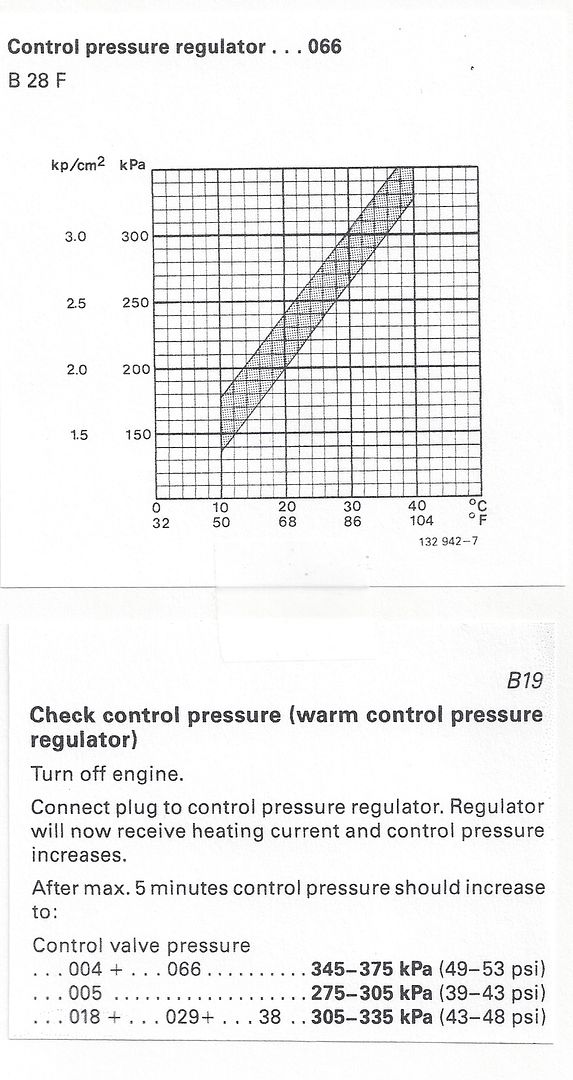

I measured the main pump pressure at about 75 psi within specs and ‘control pressure’ cold at 63 psi, low end of specs. Measured the pressure between the fuel distributor and cold start injector at about 73 psi which is within specs.

I pulled the injectors and duct taped them to baby bottles, jumped the fuel pump relay and filled them to about the 75cc level.

One, 4, 5 and 6 cylinders were all within eyeball of that 75cc. Number two was at about at the 50cc level and 3 was at a little over 25cc.

The spray pattern observed through the 80% clear baby bottles was, on all injectors, while not ‘perfect’ was close enough for me. All had a uniform circular pattern without any streams imbedded in the pattern.

Obviously, I have to resolve the significant different in volume on the #2 and #3 cylinders. Can the injectors be the problem? Or is this a fuel distributor problem?

Ignition timing is correct and CO adjustment is at 43% dwell. NO POWER.

I think I have addressed COMPRESSION, IGNITION TIMING and FUEL INJECTION. Where do I go from here?

I hate to even use the words but could Elroy have screwed up the cam timing?

Someone mentioned transmission issues but I have driven the car and counted shifts; it seems to start in low and up shift twice.