That tool worked great, popped the solenoid out without issue. I found this guide for disassembling the OD unit which has been super helpful: http://www.buckeyetriumphs.org/technical/jod/JOD1/JOD1.htm

-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M46 P-Type Overdrive Rebuild...tips tricks?

- Thread starter oifish

- Start date

Did you shake it before disassembling it?

??

Shake the solenoid as if you were shaking a spraypaint rattle can. If it rattles freely, that is a good indication that the internals are OK.

Hmm, I'll give it a shake tonight. The whole OD unit leaked like a sieve anyways, so new seals and o-rings can't hurt. The solenoid would always engage without a problem, but then it would drop out of overdrive once warmed up. I definitely plan to bench test the solenoid before making any assumptions.

It looks like the piston o-rings are the black rubber type, so I'm glad I won't need to upgrade the pistons.

Bobbyz

New member

- Joined

- Jun 2, 2013

- Location

- Park Rapids MN

That tool worked great, popped the solenoid out without issue. I found this guide for disassembling the OD unit which has been super helpful: http://www.buckeyetriumphs.org/technical/jod/JOD1/JOD1.htm

That's the site I used during the rebuild of my J type, had a couple of manuals too but the site gives real tips.

Used another site for the M41 but it's a relatively straight forward transmission rebuild.

A wooden dowel sanded down and cut to length is handy for holding the lay shaft bearings in place during reassembly.

Remember that lay shaft, shaft is bigger on one end. I forget which now but it has to go in and out the right way! A bigger hammer is not your friend here.

hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

I have one of the tools IPD used to sell. It's a short piece of 1" hex steel with 2 pins on one end.

I also just got one of the OE Volvo tools last week. I haven't even had a chance to use it yet.

As for the lay shaft, the thicker end goes in the rear of the trans, so always tap the shaft out from the front.

I also just got one of the OE Volvo tools last week. I haven't even had a chance to use it yet.

As for the lay shaft, the thicker end goes in the rear of the trans, so always tap the shaft out from the front.

Redwood Chair

- Stock PSI Or Bust -

- Joined

- Mar 23, 2007

- Location

- Ocean Beach S.F.

My homemade tool (3 foot length of 1" square tube steel with 2 bolts about 15mm apart at the end) worked great for the 2 larger plugs, but the chincy bolts started to yield when removing the smaller center plug. A little tappa tap tap with a punch was enough to break it free.

I came across this fun surprise after removing the pressure plate. I guess the prior owner sheared off one of the flywheel bolts. The broken end came out easy enough though, just used a punch and hammer to back it out. The rear main seal looks ok but I'm going to go ahead and replace it anyway.

Attachments

So the PO busted off the head of the bolt but left the rest of the bolt in there, that you were easily able to easily back out? Unbelievable! Bet they used a zip gun to run them in.

Yea, I was super relieved that it backed out so easily. He also stripped one of the hex screws for the pressure plate. Vice grips popped that loose.

The kit doesn't come with the piston seals for P type OD's, so you'll need to buy them separately.

https://www.ipdusa.com/products/7349/105752-p-type-overdrive-piston-seal

I discovered the kit also doesn't include the gasket for the high pressure filter (#6814456) which got ripped up trying to remove it. Tasca has them for cheap so I added one to the order of new pressure plate and flywheel bolts. Solenoid o-rings were not included either, so I'm the owner of 100 -007, -010, and-014 Buna-N o-rings. If any else needs a couple to refresh their OD solenoid let me know.

Attachments

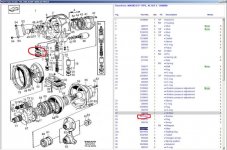

Is there any particular alignment of the holes for the dashpot sleeve and reduction valve during re-assembly? Part #23 and #18. There are holes in each and a hole in the cylinder wall. I didn't see any mention in the ipd guide or the buckeyetriumph OD site.

Simi

Upsetti Spaghetti

- Joined

- Jan 19, 2012

- Location

- Orlando, FL

I don't remember having to align them upon assembly.

I rebuilt my m46 OD once, turns out the pressure spring broke in half, causing it not to build pressure after it warmed up. Replaced the spring and it was good to go.

I did pull off the OD while leaving the trans in the car. Was able to flush the whole thing out and inspect it all. For anyone who needs to take the 3 plugs out of the bottom, i used an adjustable wrench and two drill bits. It worked perfectly.

It may seem intimidating at first but all the serviceable components are relatively easy to get to, it just sucks trying to find replacement parts.

I rebuilt my m46 OD once, turns out the pressure spring broke in half, causing it not to build pressure after it warmed up. Replaced the spring and it was good to go.

I did pull off the OD while leaving the trans in the car. Was able to flush the whole thing out and inspect it all. For anyone who needs to take the 3 plugs out of the bottom, i used an adjustable wrench and two drill bits. It worked perfectly.

It may seem intimidating at first but all the serviceable components are relatively easy to get to, it just sucks trying to find replacement parts.

Same thing happened to mine (broke PRV spring). Where did you find a replacement spring?I rebuilt my m46 OD once, turns out the pressure spring broke in half, causing it not to build pressure after it warmed up. Replaced the spring and it was good to go.

Wellll ****. Everything is back together. New clutch is nice.... but the gd overdrive just kicks in and out. worse than before now.... maybe the solenoid is bad? I really have no idea at this point where to look. The "5" light stays lit as the OD kicks in and out

I finally had the time to clean up the wiring and made sure every connection is solid and now works just fine! The OD is super smooth now. What sucks is that it still leaks. I'm going to remove the unit from the trans and put some gasket sealer on in combination with the paper gaskets.