alschnertz

Enough already!

- Joined

- Oct 4, 2009

- Location

- CT

1986 745T, 157,000 miles.

I found that the #1 fuse (fuel pump, Engine Management, ETC) is getting very hot. Almost to the point of not being able to touch it.

I've read that the main fuel pump should draw 6.5 amps.

Where would I check that? I connected my amp meter across the #1 fuse and found it was drawing between 10.5 and 12.1 amps. Seeing that high amperage, I elected to replace the main pump. So I put the new pump in and am still drawing 11.5 amps across the #1 fuse at idle.

Maybe that's a combination of the pre-pump + the main pump?

When I replaced the fuse panel a few years ago (due to meltage), I was very careful to clean and solder all the crimp connections. All were very clean to begin with. At that time, I replaced the fuel pump relay and drilled cooling holes in the relay body too. Additionally, I removed the #1 wires from the fuse panel and replaced them with a separate "stand alone" 30 amp fuse holder (though I only use a 20 amp fuse).

Just to be clear, after isolating the #1 wires from the fuse panel, the fuse panel and fuel pump relay do not get hot anymore.

Is it likely that the original pump was fine?

Is 11.5 amps across #1 normal?

Should I really be able to burn my fingers by touching the #1 fuse? That can't be right.

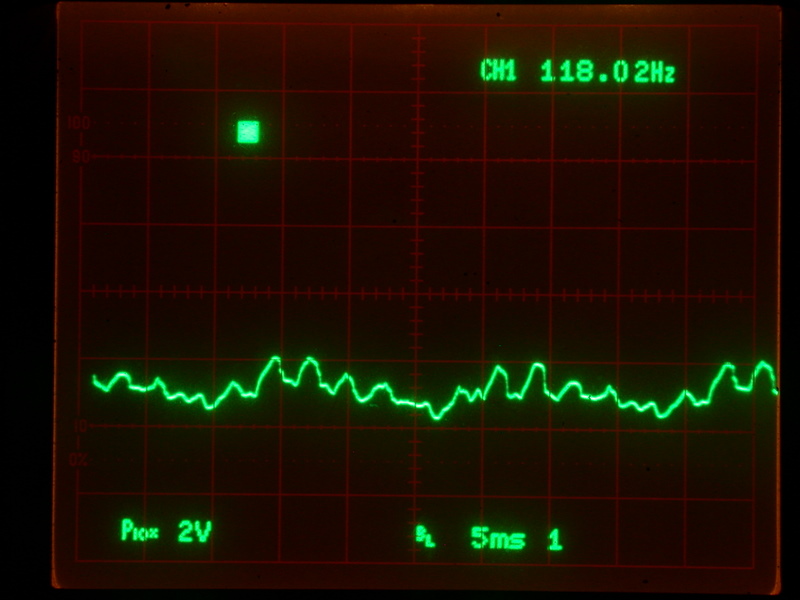

Could the Engine Management or ETC be causing this? The engine does have a slight intermittent hiccup at idle.

I found that the #1 fuse (fuel pump, Engine Management, ETC) is getting very hot. Almost to the point of not being able to touch it.

I've read that the main fuel pump should draw 6.5 amps.

Where would I check that? I connected my amp meter across the #1 fuse and found it was drawing between 10.5 and 12.1 amps. Seeing that high amperage, I elected to replace the main pump. So I put the new pump in and am still drawing 11.5 amps across the #1 fuse at idle.

Maybe that's a combination of the pre-pump + the main pump?

When I replaced the fuse panel a few years ago (due to meltage), I was very careful to clean and solder all the crimp connections. All were very clean to begin with. At that time, I replaced the fuel pump relay and drilled cooling holes in the relay body too. Additionally, I removed the #1 wires from the fuse panel and replaced them with a separate "stand alone" 30 amp fuse holder (though I only use a 20 amp fuse).

Just to be clear, after isolating the #1 wires from the fuse panel, the fuse panel and fuel pump relay do not get hot anymore.

Is it likely that the original pump was fine?

Is 11.5 amps across #1 normal?

Should I really be able to burn my fingers by touching the #1 fuse? That can't be right.

Could the Engine Management or ETC be causing this? The engine does have a slight intermittent hiccup at idle.