-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dialing in LH2.4 on the General Leif and dyno tuning basics?

- Thread starter klr142

- Start date

Update on the varying idle speed and AFR: We swapped in an 850 NA throttle body with the 960 TB's shaft so we could use the LH2.4 throttle position switch and the idle is now stable! We are also able to hold the the rpm around 1200/1300 now with just a smidge of throttle instead of it being over 2500rpm with just a hair of throttle. MUCH better for driving around in "traffic" - I mean, the pits.

Mainly because that's how my car and our race car have always been? If the tune is decent enough, it doesn't change too much from initial settings and it ends up being fine while still retaining the ability to fine tune(relatively speaking) for stoich in the lower load areas that I haven't really tuned.

That being said, we definitely don't need to run it closed loop, so I just shut it off and will leave it off now. I need to dial in the low load stuff better after our dyno session played with a bunch of stuff, though.

Hey Jaybee!Hi Kyle

Why on earth would you turn the lambda feedback back on again and mess up all your tuning effort ???

I have driven all my volvos withouht lambda feedback the last ten years and never had any issues with that whatsoever. even passes the tech inspection every timeThe sond is attached but not operative

Mainly because that's how my car and our race car have always been? If the tune is decent enough, it doesn't change too much from initial settings and it ends up being fine while still retaining the ability to fine tune(relatively speaking) for stoich in the lower load areas that I haven't really tuned.

That being said, we definitely don't need to run it closed loop, so I just shut it off and will leave it off now. I need to dial in the low load stuff better after our dyno session played with a bunch of stuff, though.

WINNER!Noise

One day, we will. It probably would've saved us 30-45 minutes on the dyno today(about 2.75hrs total spent today with more fine tuning to be done but it was good enogh).step 1) throw LH in the trash and install an ecu which is more workable for a not exactly street mannered engine like LH was designed for.

Whats that in dubyuh-aich-pees?1.21 gigawatts

Closer than the above answers!115 wheel horsepower.

Last edited:

Jerd

Active member

- Joined

- Mar 1, 2008

- Location

- Vancouver WA

What RPM are those peaks at? Really nice!

122power

dude

- Joined

- Feb 20, 2009

Damn dude

Thanks guys! Here's a massively long post in true Kyle fashion.

First off, the varying idle speed and AFR was fixed by installing a 850 non-turbo throttle body with new seals(a/c o-ring on the TPS and a valve stem husher on the throttle return spring side) on the engine. We smoke tested the intake and found a little bit of leakage out of the throttle shaft of the 960 throttle body. The 850 throttle body required re-using the 960's throttle shaft to have the notch for the throttle position switch be in the right place. We replaced the seals as mentioned above when taken apart. The idle is now stable and the AFRs at idle are now stable. The wedge on one side of the NA 850's throttle plate made it so we can actually hold 1200-1300rpm with just barely cracking the throttle instead of it instantly wanting to be over 2500rpm! That made a HUGE improvement in the ability to drive this thing around at low throttle openings(parking, pits, etc.). WAY BETTER! Who knows how much of that improvement was due to the wedge instead of the fixed vacuum leaks. I'm not going to bother finding out any time soon.

Here's what we did on the dyno:

1. We started the dyno time by playing with Injector Constants 1(IC1) and 4 to try and make sure the car is using all of the load map. I ended up settling on a mixture of both being adjusted, instead of one or the other being adjusted. It's not perfect and could be dialed in more, but it's better than before and the trace is in at least the second from the top or top load cell most/all of the time at WOT from 2500rpm up. We called that good and moved on.

2. Started dialing in the fuel mixture by leaning out(lowering) IC1 then fine tuning on the main fuel map from there. We ended up running values of 105 for IC1 and 3400 for IC4. I had to take a "ton" of fuel out of the main fuel map above 5500rpm and tweaking a few other areas to try and smooth out the curve.

3. The car had a significant lean spot around 5200rpm(as seen in the "2nd" run below on the dyno graph picture), so I started changing the RPM Scale for the main map to give me a column there that would allow be to fine tune it better. I got more resolution at higher rpm and less resolution at lower rpm, especially around low rpm/idle where the car doesn't really need much adjustment. I think I want to go back and give it even more resolution in our 2500-7000rpm range that we normally race in so I can get it even closer dialed in. NOTE: At this point I had forgotten that I had some WOT fuel add turned on still and I did not go back to zero it all out. I don't know if it actually works, but once we get the wideband working again(or replaced) I'd like to turn it off and fine tune the main fuel map more. If I am not satisfied with that, then I'll try adding the WOT fuel again.

4. Once we were satisfied enough with the fuel side of things, we moved onto the ignition. We first verified that the proper load cells were being pulled from and they were(top 2 mostly). Step two was take the top three load rows and drop them all 2? to see how the power changed. It didn't change! That suggested that we had more timing than we needed and there were no losses by retarding the ignition timing. We then took out another 2? and found the power drop everywhere so we added that last 2? back in and verified we were back where we started. We did not get around to trying smaller amounts than that or going into adjusting any of the lower load areas of the map. Maybe another day, or maybe another day with different, modern engine management system...

5. Next up, camshaft timing! We started with the gear set at 3? advanced which is where RSI had it in the past and ran the last race with no complaints about the power curve at all. At this setting, the timing mark for the cam was basically straight at the stock TDC mark on the timing cover. We tried retarding the cam 3? first and lost torque everywhere except at high rpm. It lost 7/8wlb-ft from 2500-4500rpm and the losses started shrinking gradually to where there were no losses at 6200rpm and above that it climbed up to the retarded setting having barely 1wlb-ft more at 6500-fuel cut around 6900rpm. We then instead tried advancing the cam 3?(6? advanced from previous setting) and our torque went up 1-3wlb-ft from the initial numbers below 4500rpm but matched torque until 5200rpm where it crossed and started dropping. At 5600rpm it was down 2wlb-ft, at 5900 it was down 3, at 6300 it was down 4 and at 6500 it was down 6 and at 6700 it was down 7. Not huge differences, but there! We're in the ballpark for sure with our initial setting and did a final pull with it set back to "zero" at 3? advanced on the gear. That was our final run for the day and the 3rd run on the posted graph.

Lengthy cam timing side note: I never paid much attention to people saying you need to adjust the cam timing by X amount for each Y amount the cam is brought closer to the crank. On my street car and every iteration of the General Leif's 8V engines, I just set the cam gear as close to the stock timing mark as I could and ran it. When the cam gear was adjustable, I would play with it to see where I liked the power curve best(or to meet my needs at the time; track/street). Usually that would be somewhere around "straight up" to 4? advanced(my street car had .040" off the head with a .040" headgasket at one point which is about .047" closer cam/crank relationship). With this 405 head shaved around .080" on a 2.6L B23 and ENEM C2 copy camshaft, 3? advanced made the best power with RSI's setup at the time(running E85 and a fancy header). They made somewhere around 178whp if I remember correctly. We ran that on pump gas with the same setup and it was really quick, but we never got really good testing on it as the motor was having some issues from the get go and blew up in the qualifying session for the first race with it in the car. Our current setup which has another .040" shaved off(.123"/3mm total) so I didn't think it would necessarily be optimal but obviously would work to start with. I think people have said something like it's 1? retarded for each .010" closer the cam is to the crank, so if you take .080"/2mm off the head, just set the camshaft to the stock timing marks and you'll actually have advanced it a tooth from where it was previously and all will be happy. Us having another .040" off the head and needing about 3? advance on the cam gear is pretty close to that suggestion.

From our Facebook Page:

And thanks to Mr. Culberro here for the dyno shop referral!

In response to Billy seeing our AFR jump at 5200rpm for the 2nd run:

In response to Jonathan saying that's pretty good power out of the setup:

First off, the varying idle speed and AFR was fixed by installing a 850 non-turbo throttle body with new seals(a/c o-ring on the TPS and a valve stem husher on the throttle return spring side) on the engine. We smoke tested the intake and found a little bit of leakage out of the throttle shaft of the 960 throttle body. The 850 throttle body required re-using the 960's throttle shaft to have the notch for the throttle position switch be in the right place. We replaced the seals as mentioned above when taken apart. The idle is now stable and the AFRs at idle are now stable. The wedge on one side of the NA 850's throttle plate made it so we can actually hold 1200-1300rpm with just barely cracking the throttle instead of it instantly wanting to be over 2500rpm! That made a HUGE improvement in the ability to drive this thing around at low throttle openings(parking, pits, etc.). WAY BETTER! Who knows how much of that improvement was due to the wedge instead of the fixed vacuum leaks. I'm not going to bother finding out any time soon.

Here's what we did on the dyno:

1. We started the dyno time by playing with Injector Constants 1(IC1) and 4 to try and make sure the car is using all of the load map. I ended up settling on a mixture of both being adjusted, instead of one or the other being adjusted. It's not perfect and could be dialed in more, but it's better than before and the trace is in at least the second from the top or top load cell most/all of the time at WOT from 2500rpm up. We called that good and moved on.

2. Started dialing in the fuel mixture by leaning out(lowering) IC1 then fine tuning on the main fuel map from there. We ended up running values of 105 for IC1 and 3400 for IC4. I had to take a "ton" of fuel out of the main fuel map above 5500rpm and tweaking a few other areas to try and smooth out the curve.

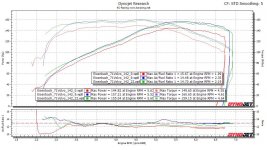

3. The car had a significant lean spot around 5200rpm(as seen in the "2nd" run below on the dyno graph picture), so I started changing the RPM Scale for the main map to give me a column there that would allow be to fine tune it better. I got more resolution at higher rpm and less resolution at lower rpm, especially around low rpm/idle where the car doesn't really need much adjustment. I think I want to go back and give it even more resolution in our 2500-7000rpm range that we normally race in so I can get it even closer dialed in. NOTE: At this point I had forgotten that I had some WOT fuel add turned on still and I did not go back to zero it all out. I don't know if it actually works, but once we get the wideband working again(or replaced) I'd like to turn it off and fine tune the main fuel map more. If I am not satisfied with that, then I'll try adding the WOT fuel again.

4. Once we were satisfied enough with the fuel side of things, we moved onto the ignition. We first verified that the proper load cells were being pulled from and they were(top 2 mostly). Step two was take the top three load rows and drop them all 2? to see how the power changed. It didn't change! That suggested that we had more timing than we needed and there were no losses by retarding the ignition timing. We then took out another 2? and found the power drop everywhere so we added that last 2? back in and verified we were back where we started. We did not get around to trying smaller amounts than that or going into adjusting any of the lower load areas of the map. Maybe another day, or maybe another day with different, modern engine management system...

5. Next up, camshaft timing! We started with the gear set at 3? advanced which is where RSI had it in the past and ran the last race with no complaints about the power curve at all. At this setting, the timing mark for the cam was basically straight at the stock TDC mark on the timing cover. We tried retarding the cam 3? first and lost torque everywhere except at high rpm. It lost 7/8wlb-ft from 2500-4500rpm and the losses started shrinking gradually to where there were no losses at 6200rpm and above that it climbed up to the retarded setting having barely 1wlb-ft more at 6500-fuel cut around 6900rpm. We then instead tried advancing the cam 3?(6? advanced from previous setting) and our torque went up 1-3wlb-ft from the initial numbers below 4500rpm but matched torque until 5200rpm where it crossed and started dropping. At 5600rpm it was down 2wlb-ft, at 5900 it was down 3, at 6300 it was down 4 and at 6500 it was down 6 and at 6700 it was down 7. Not huge differences, but there! We're in the ballpark for sure with our initial setting and did a final pull with it set back to "zero" at 3? advanced on the gear. That was our final run for the day and the 3rd run on the posted graph.

Lengthy cam timing side note: I never paid much attention to people saying you need to adjust the cam timing by X amount for each Y amount the cam is brought closer to the crank. On my street car and every iteration of the General Leif's 8V engines, I just set the cam gear as close to the stock timing mark as I could and ran it. When the cam gear was adjustable, I would play with it to see where I liked the power curve best(or to meet my needs at the time; track/street). Usually that would be somewhere around "straight up" to 4? advanced(my street car had .040" off the head with a .040" headgasket at one point which is about .047" closer cam/crank relationship). With this 405 head shaved around .080" on a 2.6L B23 and ENEM C2 copy camshaft, 3? advanced made the best power with RSI's setup at the time(running E85 and a fancy header). They made somewhere around 178whp if I remember correctly. We ran that on pump gas with the same setup and it was really quick, but we never got really good testing on it as the motor was having some issues from the get go and blew up in the qualifying session for the first race with it in the car. Our current setup which has another .040" shaved off(.123"/3mm total) so I didn't think it would necessarily be optimal but obviously would work to start with. I think people have said something like it's 1? retarded for each .010" closer the cam is to the crank, so if you take .080"/2mm off the head, just set the camshaft to the stock timing marks and you'll actually have advanced it a tooth from where it was previously and all will be happy. Us having another .040" off the head and needing about 3? advance on the cam gear is pretty close to that suggestion.

From our Facebook Page:

"Thanks again to Kris at KO Racing for letting us come play on the dyno! He was awesome! Very helpful and easy to work with. No pain, just gain! Well, we didn?t gain a huge amount but we verified where we were was good with the ignition(actually reduced timing with no torque loss) and camshaft timing. I still need to work on the fuel to smooth and lean it out some more, but it was good enough to call it quits while paying for dyno time. The car ran great with no issues, though!

The first run was our baseline run but the power numbers are probably skewed down more than actual because the oil wasn?t up to operating temperature yet. It may have been similar to how it was at Pacific earlier this month though because then it was running even richer! And our wideband is now not working. Maybe just a new sensor is needed??

The second run pictured was our best for the day and the third was our last run with the fueling a little more dialed in(but not done yet!). 157whp around 5,500rpm and 160wtrq around 4,600rpm with a nice, wide powerband that doesn't lose too much for those times when we need to rev it higher than we should.

Can?t wait for PIR in less than two weeks time!

Ps. Thanks The V Shop for letting me sneak out for a good portion of the day to play race car. �� Thanks Moates, Tunerpro, my friends at Jetronic.info/Turbobricks.com for making tuning Volvo?s old engine management possible!"

And thanks to Mr. Culberro here for the dyno shop referral!

In response to Billy seeing our AFR jump at 5200rpm for the 2nd run:

" Billy, that was on our best run and the final run doesn?t have it nearly as bad because we did tune it out. That run, with the lean surge at 5200, had the highest power numbers of the day. Compared with our final run(of 23!), it averaged about 2wtrq more across the board, even in places where the AFR was the same. That being said, at 5200rpm where there is over a point of difference in the AFR(12.7 vs 13.8:1), the leaner mixture made 3.5wtrq more! So, it wants to be leaner for peak power.

I will actually try and lean everywhere else out a bit more to get it closer to 13.2:1 across the board. Our final run fluctuated between 12.1-13. I was moving the rpm range of the cells to get them closer to the spots that needed attention and reduced the resolution, per say, of the lower/idle rpm area that the stock computers prioritize."

In response to Jonathan saying that's pretty good power out of the setup:

In response to Jens suggesting getting rid of the grocery getter camshaft:"Thanks! Factory exhaust manifold(with your downpipe and merge that flares to 3?) and ENEM?s mild K13 camshaft. Our Dynomax super turbo muffler isn?t straight through, either, so there?s more power to be had if we made something custom and went larger on the cam. I like the powerband though where it is as that?s the rpm range and power range we want to be in!

We weren?t ignition timing limited, we actually retarded it from where I had it and didn?t lose any power. Next time the head comes off we?ll get some tighter squish with a thinner headgasket and bump the compression another .7 or so by doing that."

"For our final run, the AFR varied between 12.1:1 to 13.0:1. I want to flatten it out all closer to 13.0-13.3:1 for better efficiency and it seemed like it made a tiny bit more power as well.

We could go to a more aggressive camshaft in the future, but right now we like how much torque it has at 3000rpm because sometimes we need to drive around at that low of rpm to conserve fuel and in tight corners. It's an endurance race car and we should be performing towards the front of our class with this much power after we dial the rest of the car in more along with a solid set of drivers. If we picked up another 10-20hp with a larger camshaft and a larger exhaust(it's still just a factory exhaust manifold with a dual downpipe going into a custom merge that flares up to 3"), we would go through more fuel and be put into a higher class where we would not be competitive. It would be fun, though, for sure!

For all we know, there could be some other restrictions above 5500rpm because after that the required fuel dropped quite a bit to keep the AFR from going too rich."

Attachments

Last edited:

shoestring

Well-known member

- Joined

- Jun 20, 2009

- Location

- Swampscott, 01907

Great result!

- Joined

- Oct 21, 2004

- Location

- BFE Desert east of Cali

On the cam timing, I actually did the math on mine when I built it up. I forget the numbers taken off the block and head now, been years, but between headgasket choice and the amount trimmed from block and head, it came out to .030" shorter than stock. I timed the came, found out I did in fact need 3* advanced to get the cam straight up, so the .010"/1* did come out spot on for mine.

Awesome writeup for sure! I did find pulling timing from about 10* advanced back to stock on the top 3 rows made virtually no difference in how it drove or in mileage. Spool is better, lost power when it spools though so I need to add some back in. I did also note a LOT of fuel in the high load bins, even on the stock map. I had to trim mine by 30-40% in the 5k+ ranges. Explains why it was pig rich. lol

Awesome writeup for sure! I did find pulling timing from about 10* advanced back to stock on the top 3 rows made virtually no difference in how it drove or in mileage. Spool is better, lost power when it spools though so I need to add some back in. I did also note a LOT of fuel in the high load bins, even on the stock map. I had to trim mine by 30-40% in the 5k+ ranges. Explains why it was pig rich. lol

122power

dude

- Joined

- Feb 20, 2009

Damn kyle when are you writing an lh book? Good info.

shoestring

Well-known member

- Joined

- Jun 20, 2009

- Location

- Swampscott, 01907

Yup, good writeup. Our experiences mimic yours in that cam timing is best when it's 0 or as close as is reasonable. I really like how this hangs on past peak power. Would make the gear spacing on a stock gearbox so much easier to live with.

I see that the kink at 4600 is still there, at least a little. I thought it might go away because of the B21 intake you have, but no. WHAT IS IT???!!! Our combos are different enough that we should be able to figure it out through process of elimination. Must be some kind of exhaust tuning effect...

I see that the kink at 4600 is still there, at least a little. I thought it might go away because of the B21 intake you have, but no. WHAT IS IT???!!! Our combos are different enough that we should be able to figure it out through process of elimination. Must be some kind of exhaust tuning effect...

Haha, Luke, I'm not that good! Just learning more every day about what you can do with LH on the tuning side. Mr. Jaybee and the Jetronic.info guys are doing the most with getting us awesome XDF files to use on TunerPro and permit getting things dialed in more.

Thanks Dan. On my street car I've seen more benefit at low rpm than what this dyno experience showed(when advanced 6? instead of 2 or 4 at times), so I think it depends on the rest of the setup/camshaft. Some camshafts seem to have larger differences when you move it around than others. None seem to like retarding too much from my experience, except the T cam...... Hahaha

I am also happy with how the power hangs on at higher rpm! Even with it running richer at the last race, it definitely was a benefit to let it rev way out if you're trying to accelerate as fast as possible. That's even with the really close gearing! (T5 transmission with the 2.95 first gear, 0.80 fifth gear and 4.56 rear end)

Regarding the torque curve dip... Yeah, I don't know what to say there! This setup has the stock downpipe sort of thing, but it does have the K-Jet manifold and a 405 head... Funky buisiness! It's there on all of my dyno runs with the K(around 4400 with the cam advanced 4?), H and K13. The H and K13 are between 4500-4600rpm.

Thanks Dan. On my street car I've seen more benefit at low rpm than what this dyno experience showed(when advanced 6? instead of 2 or 4 at times), so I think it depends on the rest of the setup/camshaft. Some camshafts seem to have larger differences when you move it around than others. None seem to like retarding too much from my experience, except the T cam...... Hahaha

I am also happy with how the power hangs on at higher rpm! Even with it running richer at the last race, it definitely was a benefit to let it rev way out if you're trying to accelerate as fast as possible. That's even with the really close gearing! (T5 transmission with the 2.95 first gear, 0.80 fifth gear and 4.56 rear end)

Regarding the torque curve dip... Yeah, I don't know what to say there! This setup has the stock downpipe sort of thing, but it does have the K-Jet manifold and a 405 head... Funky buisiness! It's there on all of my dyno runs with the K(around 4400 with the cam advanced 4?), H and K13. The H and K13 are between 4500-4600rpm.

We didn't do any lower load tuning, just a bulk drop of timing in the highest three or four load cells across the full rpm range. Being that it's LH2.4 and EZK, the load scale may not be something that really correlates to what you will be using(it's not kPa). I want to adjust it all further and it's not pretty by any means right now, but we did successfully race at Pacific with how it was before I adjusted things on the dyno anyway, so yeah. I'm happy to share what I have, I just wouldn't call it perfectly dialed in. I'll see if I can get some time to post up later. The really low load areas under 3,000rpm I reduced the timing a lot because with the 960 throttle body installed we couldn't hold a low rpm at the tiniest of throttle openings. The 850 throttle body with the 960 throttle shaft is much happier in that regard so I could probably bring that ignition timing back up closer to stock.Want to share the rough shape of your ignition timing map? My car is slightly more compression and slightly larger cam, but otherwise pretty similar.

(I mostly want to steal your timing map so you can still beat at Lucky Dog later when my car finally runs)

By the way, I can't remember if your engine is together yet? Does it run? Do you know the cranking compression just out of curiosity? You're running Mega or Microsquirt, right? What throttle body and intake are you using?

Being that it's LH2.4 and EZK, the load scale may not be something that really correlates to what you will be using(it's not kPa).

Yeah - I'm mostly just interested in roughly how much timing it needs up in the top few rows. The cam is so big that it likes idling around 25 degrees anyway, so I think my whole timing map might end up nearly flat...

By the way, I can't remember if your engine is together yet?

It's 90% together. I have to mount some stuff and clean up some wire routing, but it's mostly together.

Does it run?

It runs! Though I haven't done anything more exciting than puttering around the neighborhood.

https://www.youtube.com/watch?v=TcfO0hk3x4Q

Do you know the cranking compression just out of curiosity?

I don't. I suppose I should check that.

You're running Mega or Microsquirt, right? What throttle body and intake are you using?

I'm a contributor to the rusEfi project, so I'm running one of those for the ECU. I'm not decided on whether I'll run speed density or alpha-N, but either way I'll have plenty of resolution for tuning.

I'm (unfortunately) running the stock LH2.4/3.1 intake and throttle body for now, but I'll switch at some point first to an 70mm-ish Ford electronic throttle body, and a better intake.

Nice! Do more than puttering around the neighborhood!Yeah - I'm mostly just interested in roughly how much timing it needs up in the top few rows. The cam is so big that it likes idling around 25 degrees anyway, so I think my whole timing map might end up nearly flat...

It's 90% together. I have to mount some stuff and clean up some wire routing, but it's mostly together.

It runs! Though I haven't done anything more exciting than puttering around the neighborhood.

https://www.youtube.com/watch?v=TcfO0hk3x4Q

I don't. I suppose I should check that.

I'm a contributor to the rusEfi project, so I'm running one of those for the ECU. I'm not decided on whether I'll run speed density or alpha-N, but either way I'll have plenty of resolution for tuning.

I'm (unfortunately) running the stock LH2.4/3.1 intake and throttle body for now, but I'll switch at some point first to an 70mm-ish Ford electronic throttle body, and a better intake.

I'll see if I can smooth out my timing map now and post it up soon. I haven't had any time and right now I'm supposed to be researching a new washer as ours stopped working... Doh! But basically, peak timing of between 27-30? is apparently normal for high HP NA redblocks on the swedish forums and we had been running a max of 31 and are now settled at 29. I'll get a picture later!

Nice! Do more than puttering around the neighborhood!I asked for more info about the setup in the KL Racing camshaft thread.

I should have time this weekend to go for a real drive. Brakes are bled, seat is bolted down, just need to mount the coils and put the doors back on...

edit: and that timing sounds right, 27-30 is about what I though it should be. I think my map currently has 25 across the board in the top row, which might leave a few hp on the table, but also won't blow anything up.

Do it, do it! Or come to the track and hang out with us when we race!

Regarding ignition timing, start closer to 10 at low rpm and ramp your way up. I think I’m still only around 18-19 at 2000rpm as it can’t take more than that. Likely around 22-24 at peak torque for us which is between 3500-4700 or so? I still need to get a screenshot of my timing map as I started smoothing the fuel side yesterday and that’s as far as I got.

Regarding ignition timing, start closer to 10 at low rpm and ramp your way up. I think I’m still only around 18-19 at 2000rpm as it can’t take more than that. Likely around 22-24 at peak torque for us which is between 3500-4700 or so? I still need to get a screenshot of my timing map as I started smoothing the fuel side yesterday and that’s as far as I got.