It's time to get some seat belts in this thing. I need to make sure of the belt receiver buckle before I finish the drive line tunnel, so in go the seats and I did a little test fit.

That's going to work. Feels really good - shifter is in the right place, pedals feel good.

I started with the rear belts...just to get them done. I'm not going with any stockish placement. I built these adapter brackets.

They're held in with some nut plates welded to the parcel shelf.

Tada - done. These belts don't have a shoulder loop and will be covered eventually.

Next, I needed some anchor plates for back and front.

A little TIG practice.

Couple of holes and a little more welding and bingo - we're installed in the back.

These get added to the B pillar - the spacer keeps the webbing off the bodywork.

Now, the front belts are installed.

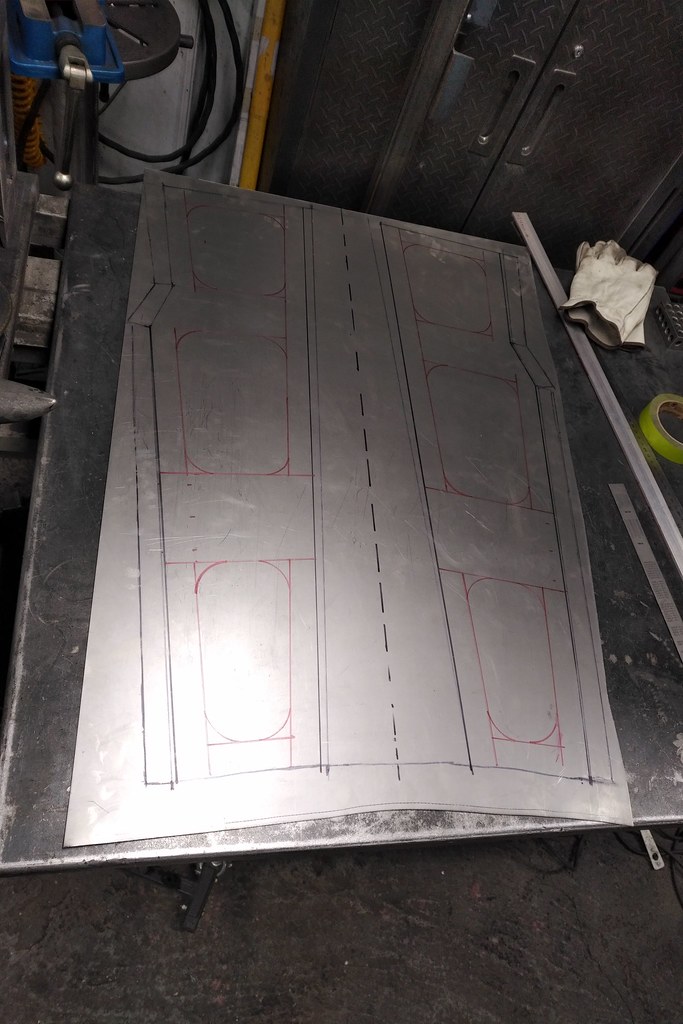

Now, I can finally get the drive line tunnel done. So a little layout work.

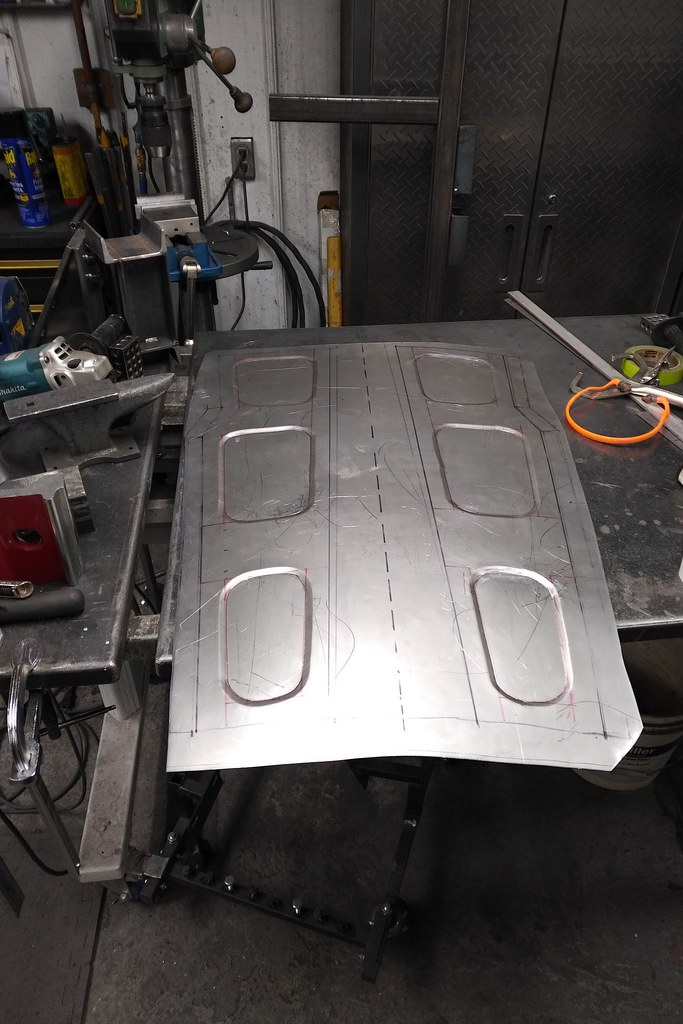

Some bead rolling.

And BAM - we've got a tunnel.

Looks good to me.

Clearance is good.

Side view - very happy with the way it turned out.

That's it for this update. Tune in on the YouTube channel if you want more details.