volvobrage

Member

- Joined

- Jan 17, 2011

I want to be your friend too!

Great progress again. One of my favorite blogs.

Thanks!!

Is really cool you like my project

Is really cool you like my project20.02.13

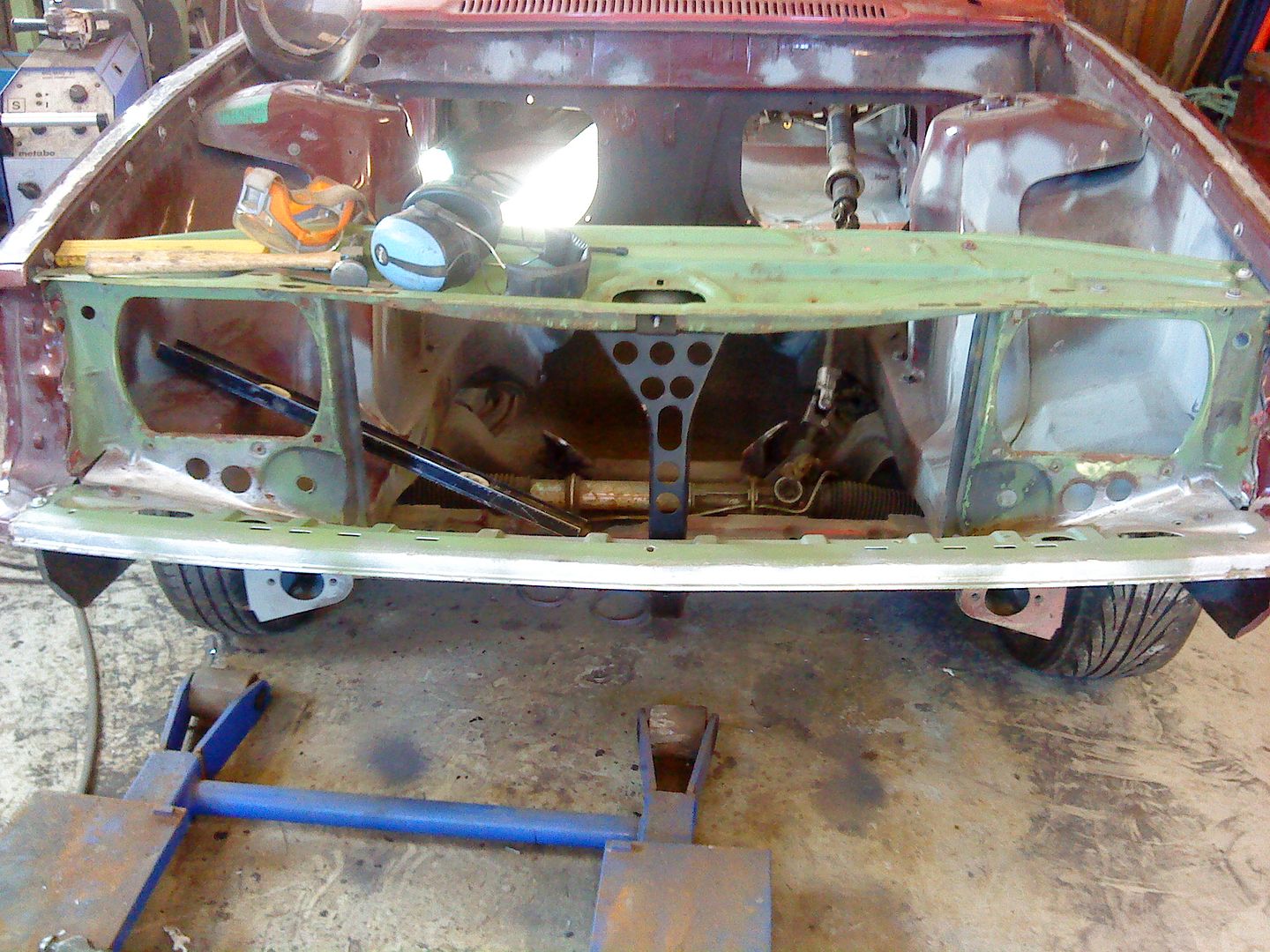

A friend helped me and ripped my tire of the second rear rim..Have been doing some math and these rims are 18x10" et25..But I have 26mm spacers on the last pictures..So when I one time in the future will order custom rims I could with a 10" wide wheel with et-1