GreatDaneShane

HBIC

- Joined

- Jul 28, 2007

- Location

- Houston, Texas

http://arduino.cc/forum/index.php?topic=8525.0 foud this. Might beof some help. Funduino nano v3.0 board came in today.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

http://arduino.cc/forum/index.php?topic=8525.0 found this. Might be_of some help. Funduino nano v3.0 board came in today.

http://arduino.cc/forum/index.php?topic=8525.0 foud this. Might beof some help. Funduino nano v3.0 board came in today.

Run time should be really fast even with an Uno. You will need a pressure transducer and a PWM (pulse width) operated valve.

There are a lot of ways to do it, but the simplest way would only take about 15 lines of code.

Pseudo code for single port WG actuator:

read sensor

if sensor reading < max pressure - error threshold;

close valve

else if sensor reading = max pressure +- error threshold;

return;

else if sensor reading > max pressure + error threshold;

open valve

end if

That code would theoretically, allow no intake pressure to the wastegate actuator and keep the wastegate closed until it hits the max desired pressure. You would probably want this to be more gradual, which would add two or three more lines of code.

If you do go for electronic boost control, you would have more control with a dual port WG actuator.

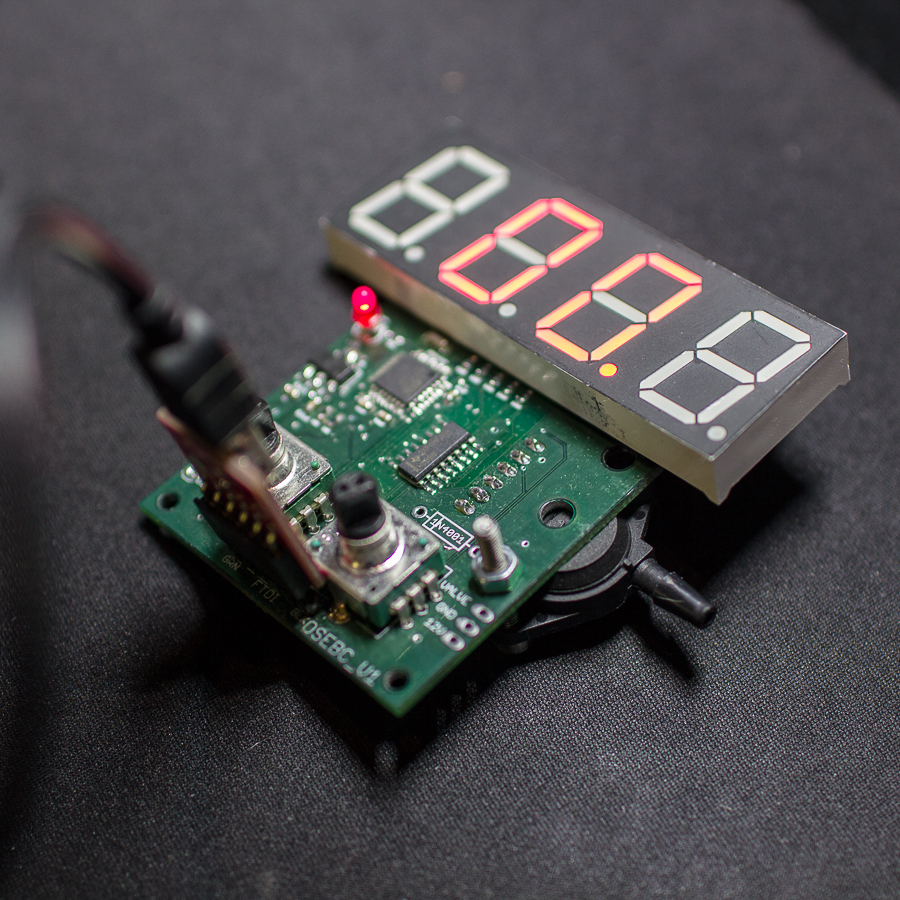

I'm building one, open source and doing a kickstarter.

Very cool. What's the deets? Any testing yet?

Shoot, I just realized we owe eachother a hang out sometime. I'm out by cityview park/kerncliff almost every day.

ms2extra v3.3.3 has the ms3 boost code now. and has always had overboost protection mandatory to enable boost control

also open source so if you can code make your own.

Arduino is powerful but you wont get it to work better than some 1990's Blitz, HKS, Apexi or any other funky old jdm controllers without giving it more inputs like Throttle position, rpm,Vss,coolant temp,intake temp, turbine shaft speed, gps, excreta. At least the MS has the hardware already there dig into the code and make it better.

guess you could make the audrino connect via can-bus to get input data.

Also a lot of them top out at 24-27psi, which is not enough for some of us here.

Pressure transducers should have the transfer function and curves available from the manufacturer. If you're trying to use automotive ones, try the factory service manual, or just stick to lab ones that you can buy at digikey etc.