dunnp2

New member

- Joined

- Sep 18, 2011

- Location

- Seattle, WA

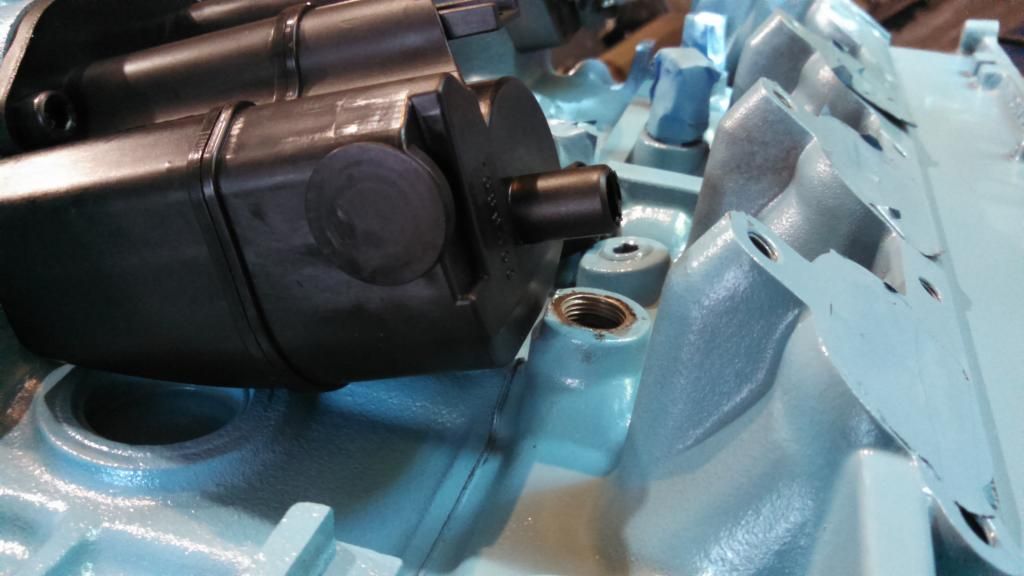

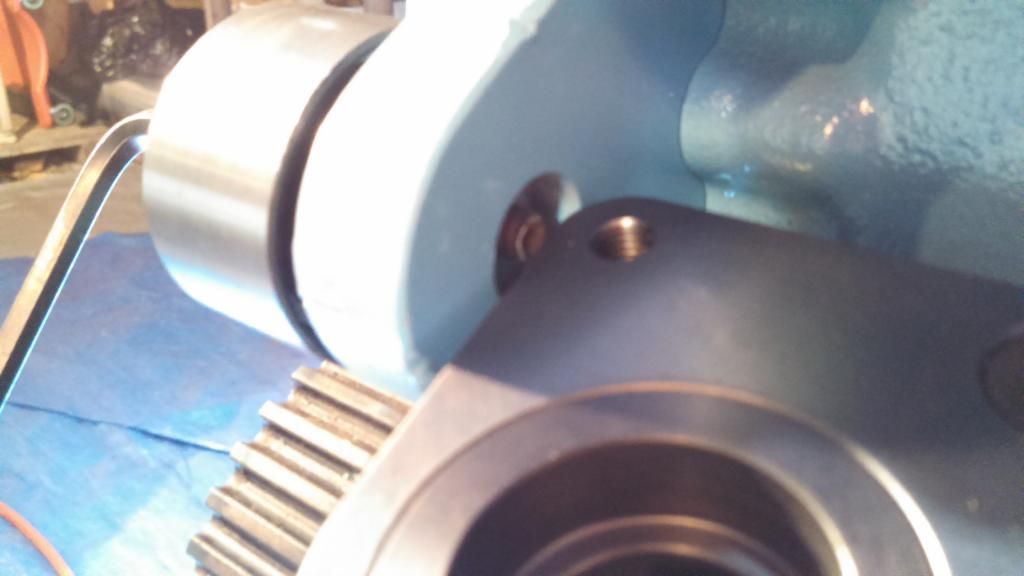

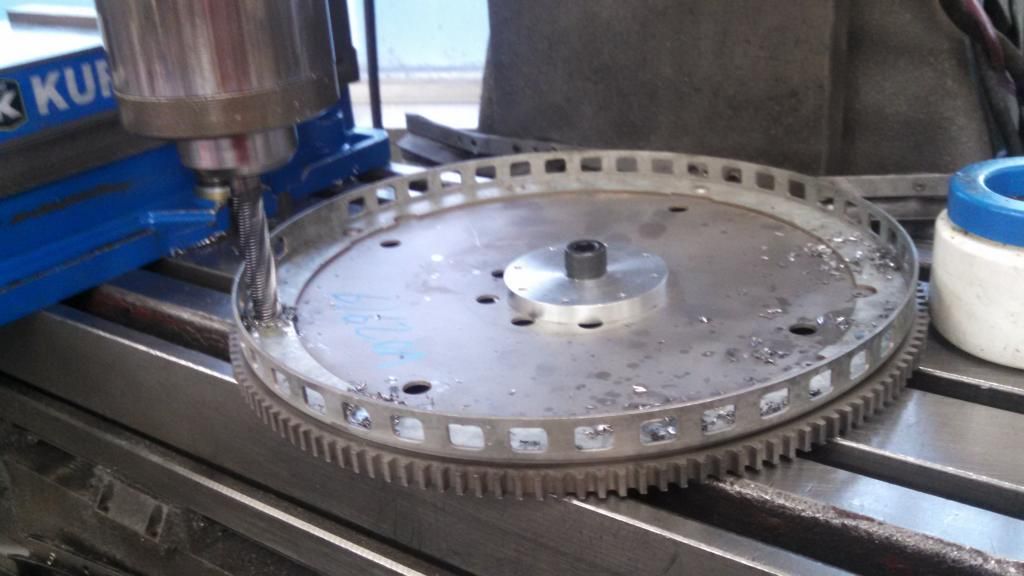

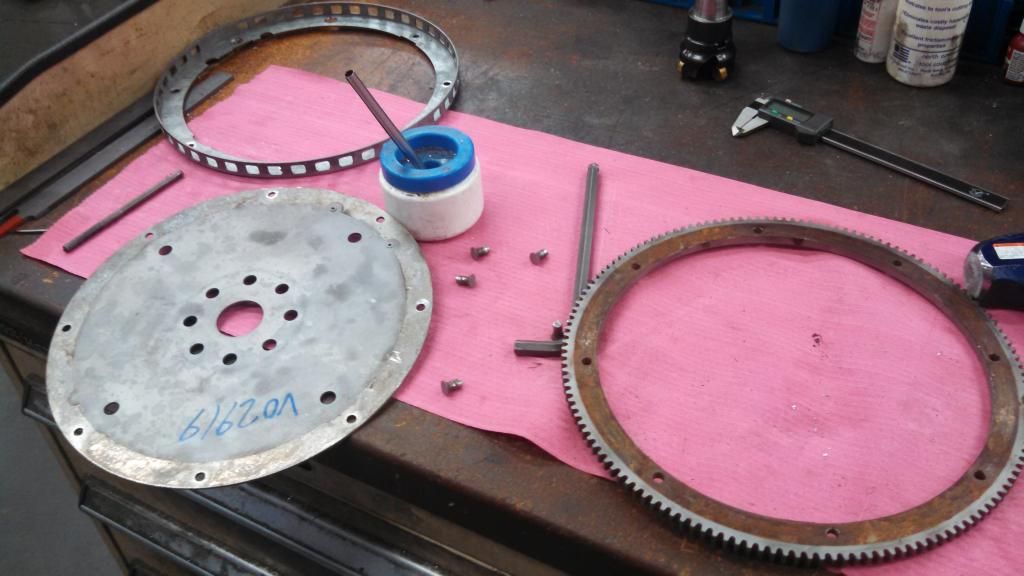

I figured I was far enough along to start a build thread. I'm planning to put a B230 into my '68 144, along with a 16v head, turbo, MS3X, GM T5 transmission, and maybe a few other goodies. The plan is for a really nice daily driver, so I'm not shooting for the moon with power and I'm not slamming it to the ground. It'll have plenty of heavy sound deadening and I'd like the exhaust to be fairly quiet. Not very exciting to talk about, but it should still be awesome to drive!

What do you do immediately after moving from New England to the Pacific Northwest? Buy a clean old Volvo.

Then, of course, you tear it apart!

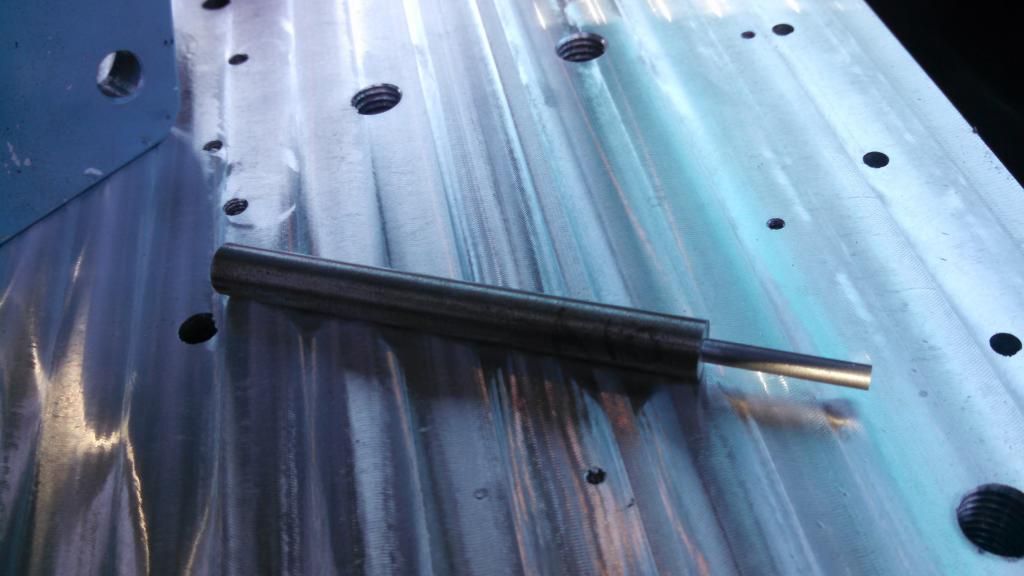

Here's a piston from the stock engine. Surprisingly it didn't feel like it lost any power, but there was a solid oil cloud coming out from under the hood at every stop light. None of the oil rings were in one piece.

The interior is done enough at this point. I fixed the rust holes, POR-15'd everything, then put down a layer of sound deadening covered by a new carpet and some knockoff ricer seats.

What do you do immediately after moving from New England to the Pacific Northwest? Buy a clean old Volvo.

Then, of course, you tear it apart!

Here's a piston from the stock engine. Surprisingly it didn't feel like it lost any power, but there was a solid oil cloud coming out from under the hood at every stop light. None of the oil rings were in one piece.

The interior is done enough at this point. I fixed the rust holes, POR-15'd everything, then put down a layer of sound deadening covered by a new carpet and some knockoff ricer seats.

Last edited: