JW240

All idiot, no savant

- Joined

- Aug 15, 2004

- Location

- The Netherlands, Europe

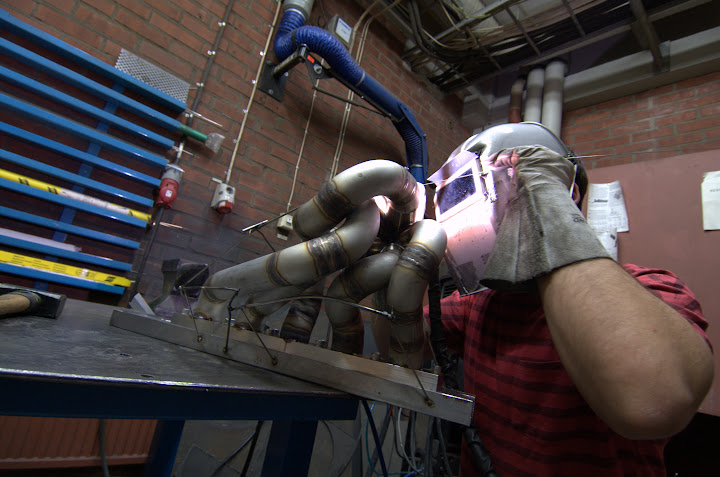

nice stuff. they are using the Cebora or the newer Esab TIG?

Very nice shop indeed. jealous.

Very nice shop indeed. jealous.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

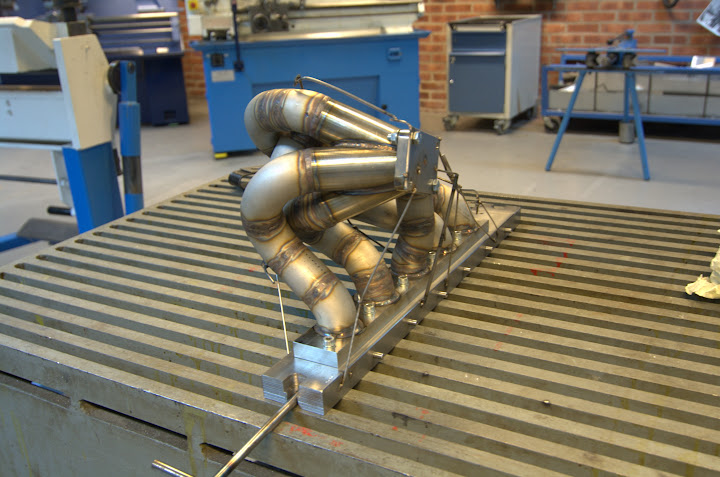

Say... this jig.. is it made for filling the header with gas so the inside of the neat gets nice ?

Last time i looked someone over the shoulders welding a header, he put it in a bathtube filled with gas to weld it through... he didnt want to tell me what gas... but i believe it was heavier than air

It should be done today.as always nice work. what schedule on the manifold?

It's 18mmDanggg is that head flange 1/2in or are the pictures decieving?

Argon.Say... this jig.. is it made for filling the header with gas so the inside of the neat gets nice ?

Last time i looked someone over the shoulders welding a header, he put it in a bathtube filled with gas to weld it through... he didnt want to tell me what gas... but i believe it was heavier than air

I dont understand.

Argon

Purity better than 99.99%

Used for TIG and plasma welding as well as a root protection when welding of all metallic materials. No ozone-reducing effect.

Marking; EN ISO 14175-I1-Ar. Group I1

Argon 4.6 (Argon Plus)

Purity better than 99.996%

Used for TIG and plasma welding as well as a root protection upon welding of all material

Argon 4.6 is recommended for welding of extra-sensitive material, where there is a very strict demand for gas purity, such as e.g. titanium and magnesium

No ozone-reducing effect

Marking; EN ISO 14175-I1-Ar. Group I1

what are you, 12?I dont understand.