Can't reply with a quote.... EDIT

You've done much work since I last checked in - looking

really good!

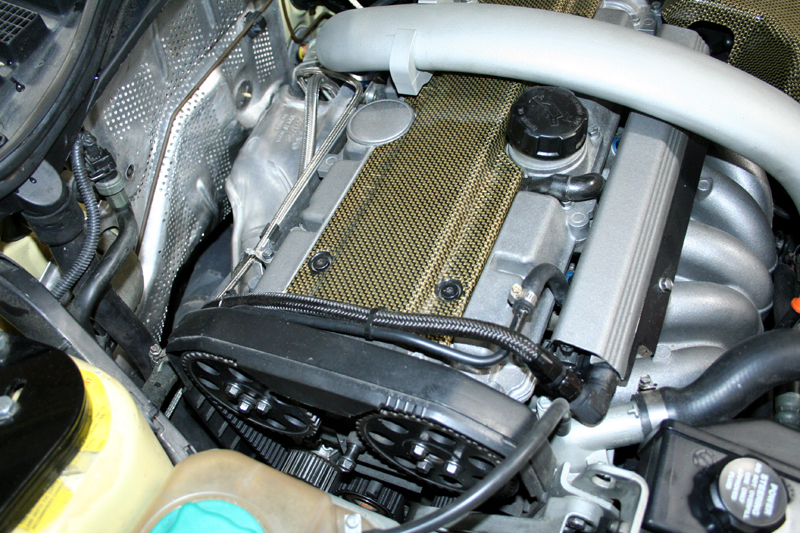

If you use a baffled drain back CC, then the oil leaving the cover won't be such an issue - but baffles under the cover really are the cure.

I used delrin mounts in my stock AWD subframe - I like that you used the entire C70 version - I have the braces lined up so as to add them later on. What did you do to resolve the AWD center support to the plate on the C70 version?

Curious why you kept the "S" shape to the DP - you could have dropped it further to the right, no? Unless on RHD models the steering column is in the way?

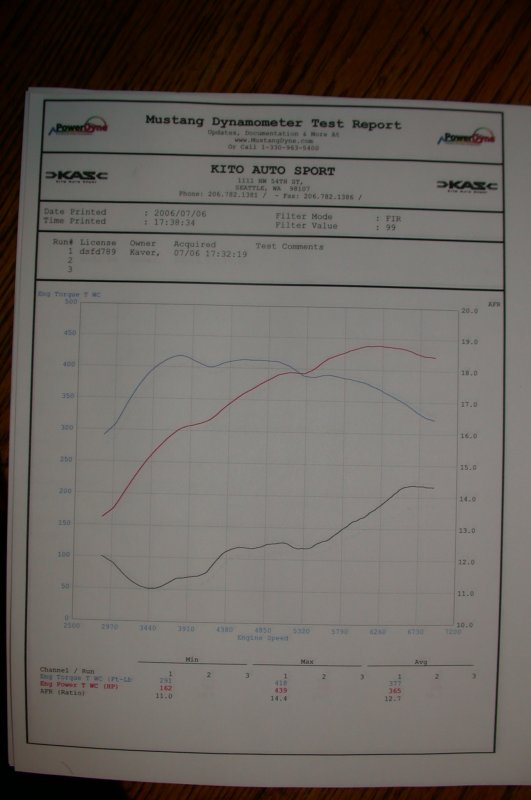

I have found the stock lines to be OK @

450AWHP - with a DW300 FP, larger volume rail & 650cc injectors @ 4bar.

After setting up the single 044 on the MY99 filter bracket, I decided to go with a surge tank with two 044's inside. I'm going to put the tank in a similar location to yours, and run 8AN line to & from the the FPR. Did you have to drop the subframe to snake the lines over? I was hoping I could feed them through & over the tank without doing so...

I just switched to 1000cc injectors, after the 650cc's were hitting over 90% duty cycle @ 1.4bar on the AWD dyno.