- Joined

- Sep 18, 2002

Looks like I can still count on turbobricks to work hard at solving imaginary problems.  Nice work!

Nice work!

Nice work!

Nice work!Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

Nice work!

Nice work!Split liners not such an issue on the 2.3

Just for the record my t5r was north of 400 whp, unshimmed, Mahles and audibly pinged for over a year while I sorted other issues and that was seven years ago. Got a note from the current owner and the car is still going as strong as ever. Just sayin...

I did generally keep the boost to 20 psi or so and redline at 7600.

Dyno logs to back that up? With significant knock, it is unlikely to not damage the motor, so either the knock wasn't as bad as you thought, or it was running so rich it just didn't matter?

He's got logs, video, pbase and a huge build thread to back it up. It's one of the most viewed build threads on TB.

http://forums.turbobricks.com/showthread.php?t=58262

On that note, a couple of years ago now I did what Capt Bondo had suggested around page two, and installed a decent sized turbo, headers, and a short runner large plenum intake. Compared with the previous setup that had a restrictive setup, I was able to make more power at lower boost, run higher revs on basically the same tune without any of the knock that was pulling timing previously

.

Because you aren't holding all that heat in. What people are failing to realize is that in terms of factors that contribute to those liner failures, 90% of it is thermal.

Of course it's way easier on the ego to say "ZOMG I made too much powerz! I broked err-thang!" than to simply say "I tried to use a bunch of stock junk to do something it was never designed for with no tuning and it smoked itself." Ooh shocking.

Nice work. 35 pages and no test/tune/dyno data at all. I'll move on to the second link now...

EDIT: There it is!

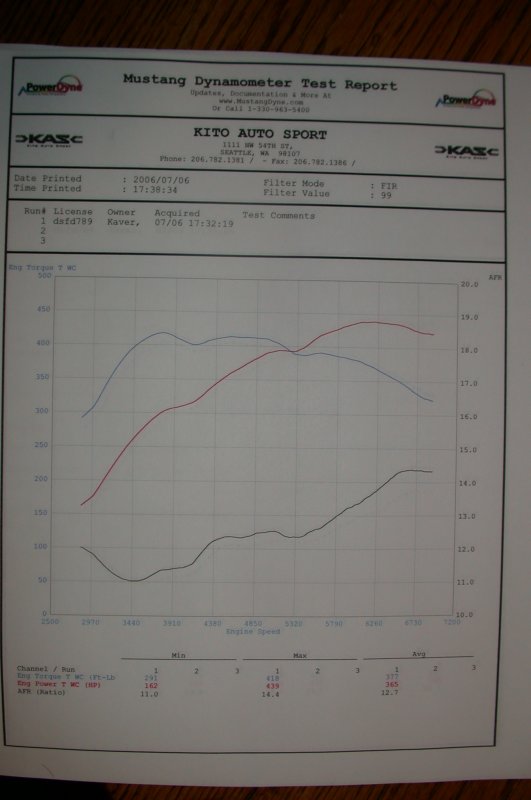

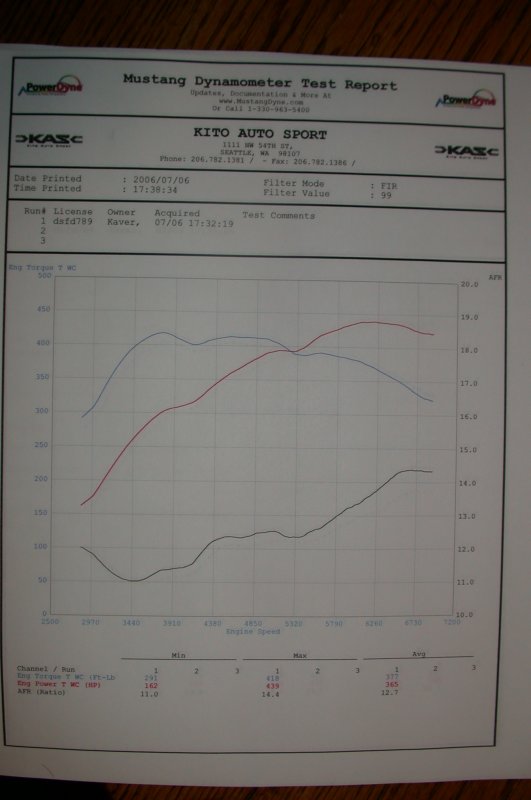

Very respectable numbers on a real dyno. Not surprisingly power drops off a little over 6K, but given the hotside used and stock intake manifold, it's understandable. Definitely needed more tuning/more fuel volume/bigger injectors, got way too lean pretty quickly.

The new wagon gets a 2000 block and head, me7 intake, ATP exhaust manifold and an 82ar gtx3076r this time. I don't want to run a header or custom intake for visual (inspection) reasons. Should still be an improvement.

I've been a big advocate of the best thing you can do to a whiteblock is get rid of the damn td04 and uncork that side of the motor.

Btw I'll take the fact you found my dyno sheet as a pseudo apology for going right to pitchfork and torch status on my post

6061 Shims, ~320WHP, about 2mm from the top

B5254T5(LPT)