canyoneagle

Striving for mediocrity

- Joined

- Aug 26, 2011

- Location

- Chapel Hill, NC

Nothing exciting to report. 29 degree temps kept my work on the car to a minimum.

Fixed the wire near the starter - it was a b%$#tch to get in there to strip/splice the wires, but I got it done.

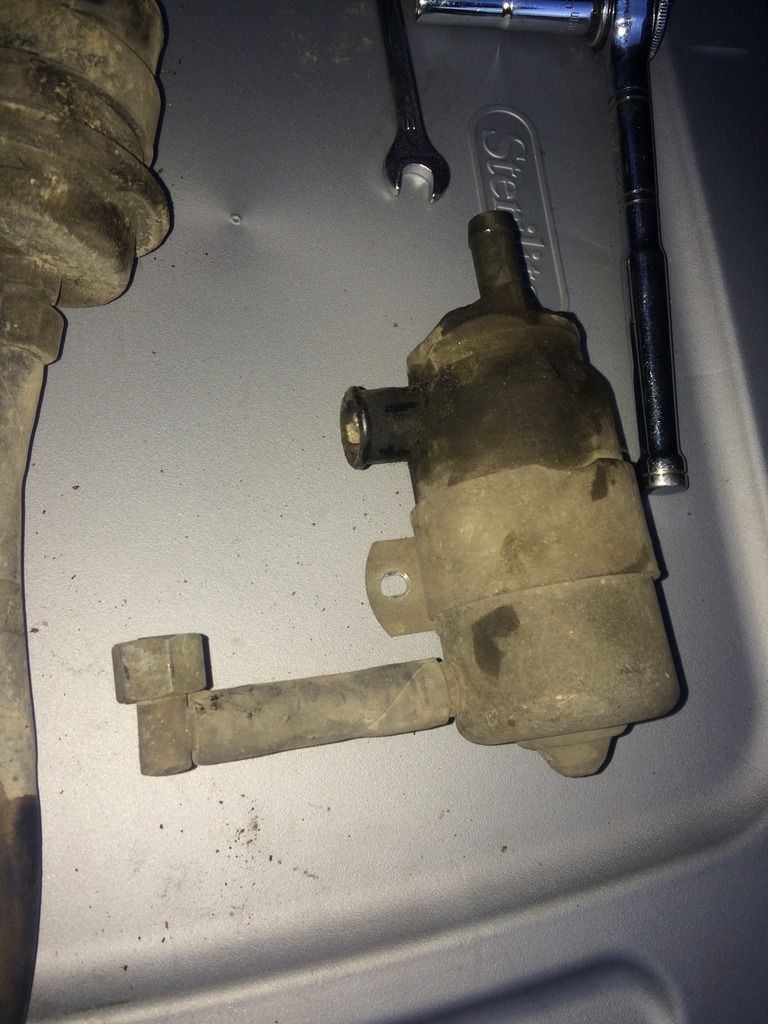

I also replaced several vacuum lines while I was at it today.

Turned the car over, still no sign of fuel. Too chilly to chase it down today.

Fixed the wire near the starter - it was a b%$#tch to get in there to strip/splice the wires, but I got it done.

I also replaced several vacuum lines while I was at it today.

Turned the car over, still no sign of fuel. Too chilly to chase it down today.