ICantDrift

New member

- Joined

- Aug 16, 2016

- Location

- Morrisville, NY/ Middleofnowhere, NY

Hey all,

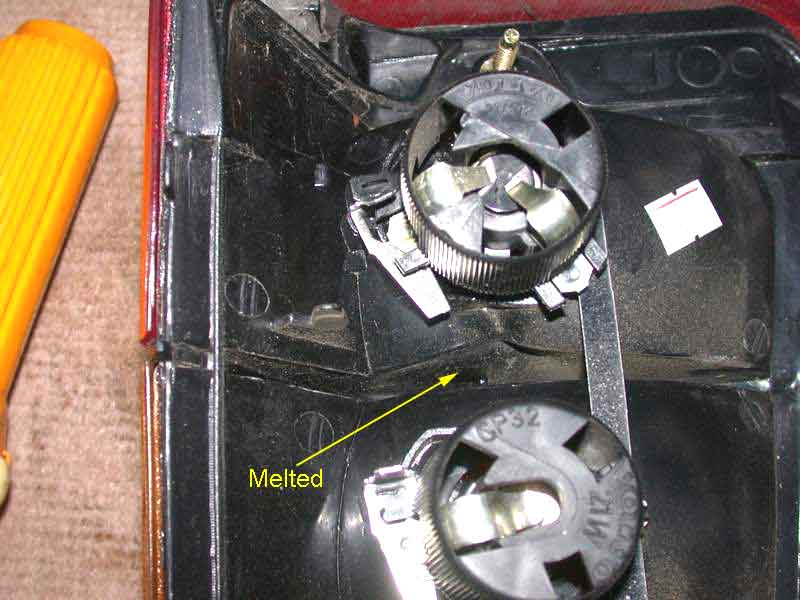

I've been fighting a non-working brake light in my '88 245 for the past few months and I'm not sure what is causing the issue. The problem is that the ground prong for the brake bulb isn't contacting the ground tab on the housing because it's getting so hot that the plastic around the ground tab is pushing into the molten plastic of the housing, away from the ground prong on the bulb. Too much heat means too much current but I'm not exactly sure why this is happening. Has anyone else experienced this and/or have any advice?

Thanks in advance

I've been fighting a non-working brake light in my '88 245 for the past few months and I'm not sure what is causing the issue. The problem is that the ground prong for the brake bulb isn't contacting the ground tab on the housing because it's getting so hot that the plastic around the ground tab is pushing into the molten plastic of the housing, away from the ground prong on the bulb. Too much heat means too much current but I'm not exactly sure why this is happening. Has anyone else experienced this and/or have any advice?

Thanks in advance