Ttownthomas

New member

- Joined

- Feb 1, 2015

- Location

- Cary, NC

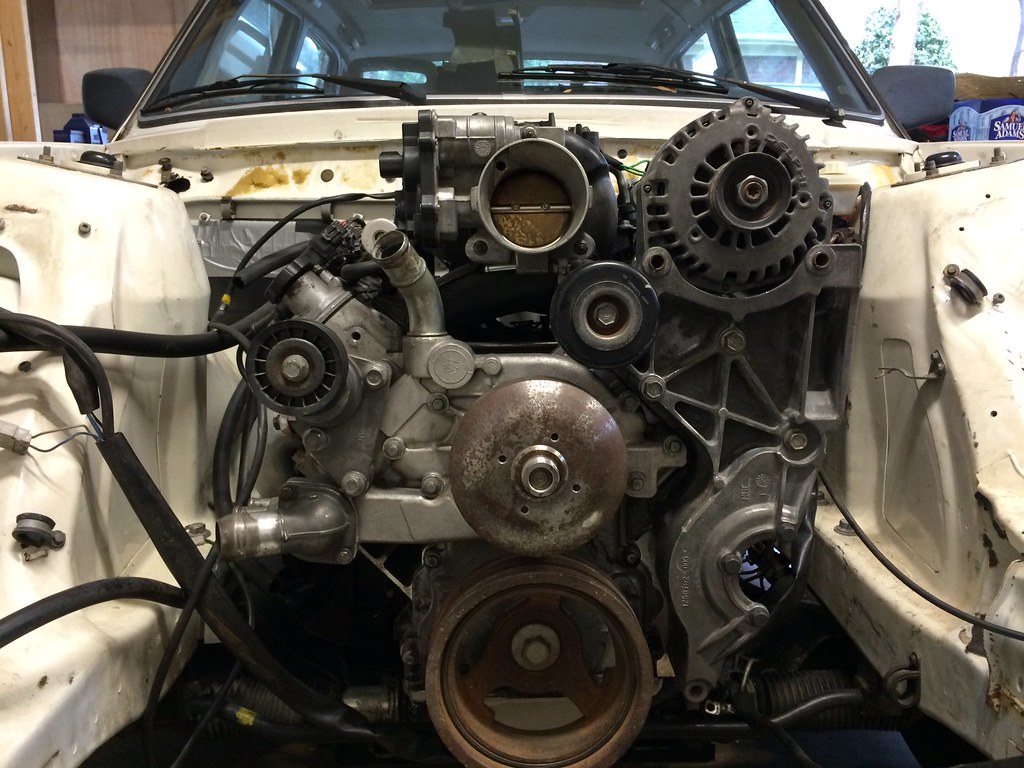

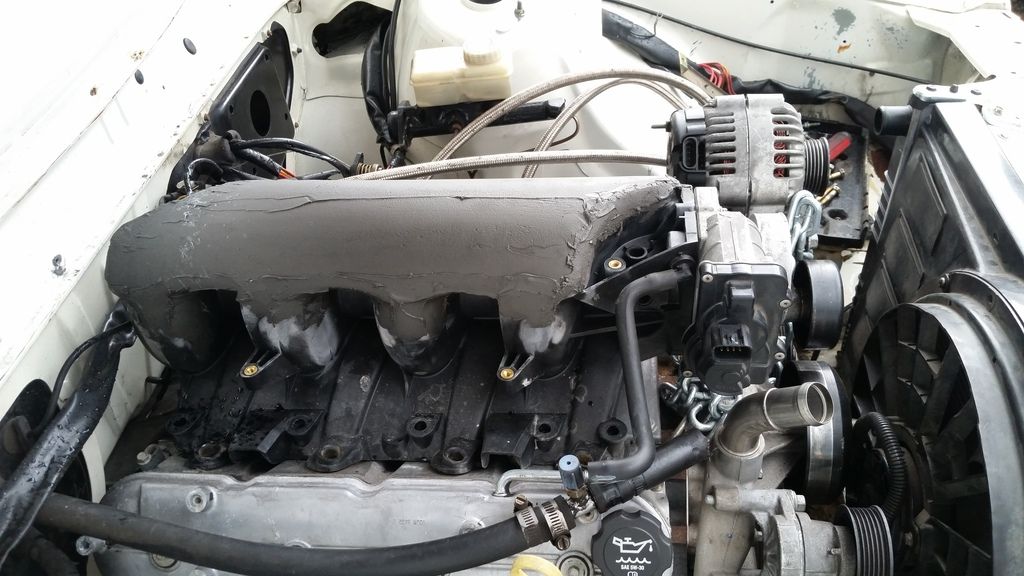

The power steering rack and the sway bar have no clearance issues now. I had to spacer down the trans crossmember by 1.25 inches to get the required clearance. I will fab up a new crossmember once I get this thing running and get the right suspension in there. Then I can measure driveshaft angle. The fit on the mounts is so close. Any taller and the truck intake wouldn't fit and any lower and it would not clear the rack and crossmember. Overall well engineered.

Last edited: