I've handled dozens of pulleys in my own cars over the years plus customer cars at work and have never noticed anything out of ordinary. Total count could be around 60-100(or more?). Imo the risk of a broken pulley is nonexistant. But of course, use 90 degree turn for oil line if you want to minimize that risk.

-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

+T Turbo Oil feed. Is this the right hole?

- Thread starter EivlEvo

- Start date

To old for this

New member

- Joined

- Sep 14, 2016

- Location

- Texas Panhandle

Weren't very early ones only one thickness? Seems there was update/recall?

VB242

I.M. Weasel

- Joined

- Sep 21, 2011

- Location

- Driving the No Malarkey Bus

It was an early pulley, I had switched to an efan. The later efan pulleys are thicker across the snout. Regardless, it happened to me it could happen again.

Xeroni

MPG?

- Joined

- Jul 18, 2009

- Location

- Santa Rosa, CA

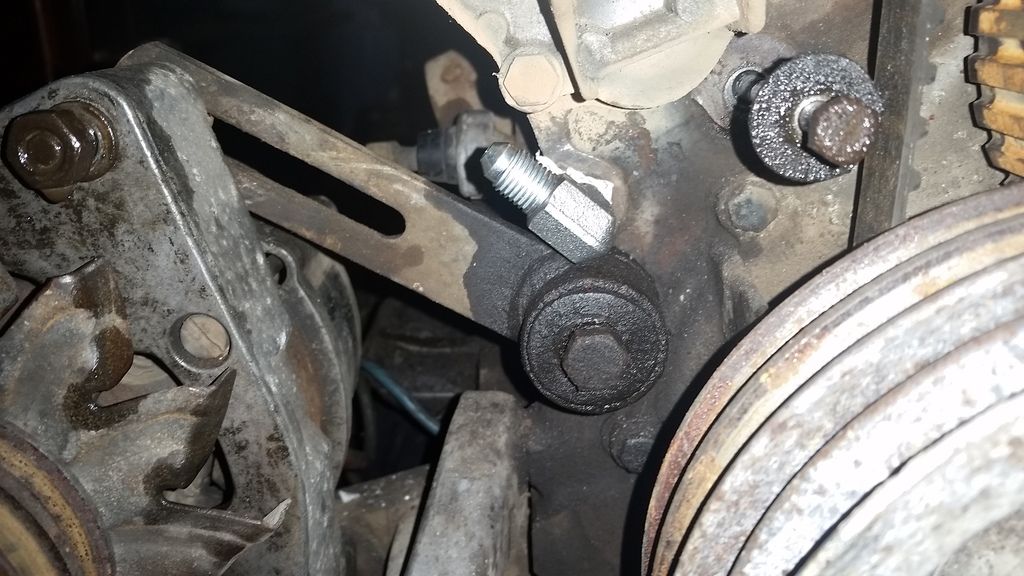

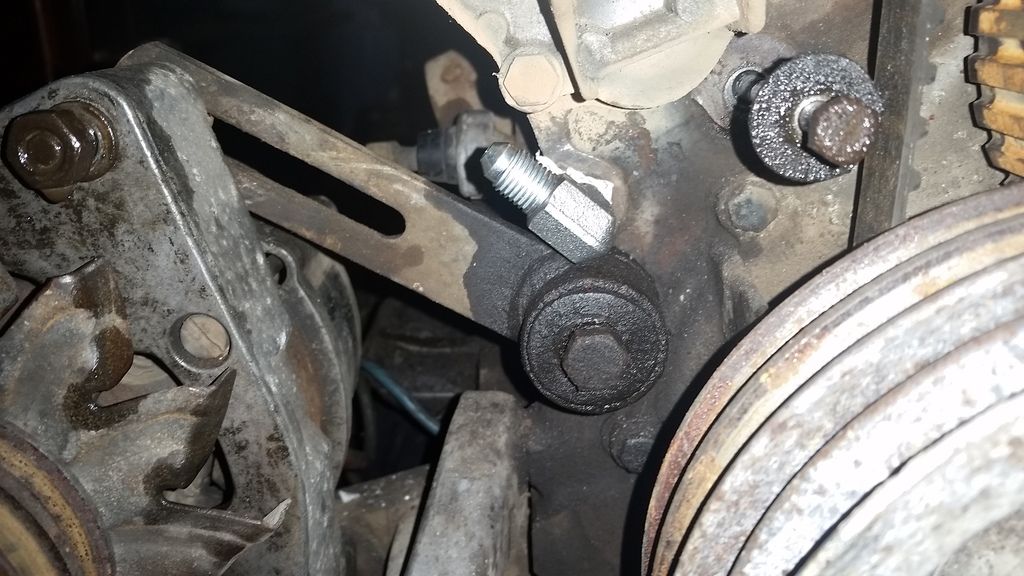

This is how I did it on my b21 block. You just have to start the adapter in the right spot so it tightens enough when it gets where you want it.

bobxyz

Board Member

- Joined

- Aug 29, 2014

- Location

- Boulder CO

How does this happen? Must have been loose already? Never seen or even heard of one before. The material and shape of the pulley don't seem to be easily brakeable if something else doesn't fail first badly.

I've handled dozens of pulleys in my own cars over the years plus customer cars at work and have never noticed anything out of ordinary. Total count could be around 60-100(or more?). Imo the risk of a broken pulley is nonexistant. But of course, use 90 degree turn for oil line if you want to minimize that risk.

Weren't very early ones only one thickness? Seems there was update/recall?

Yes, early (e.g., my B21FT, was single thickness, later B230F was double thickness). I'd be curious if there really was a update/recall.

See post #10+ http://turbobricks.com/forums/showthread.php?p=5428176