tequila_gundam_no_chaser

tequila_gundam_hug_the_toilet

- Joined

- Nov 15, 2002

- Location

- Atl

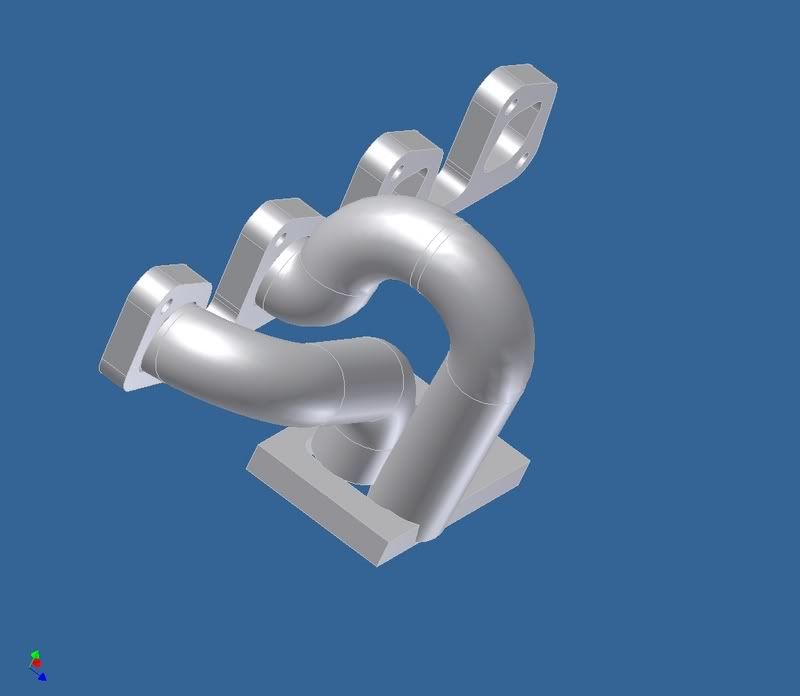

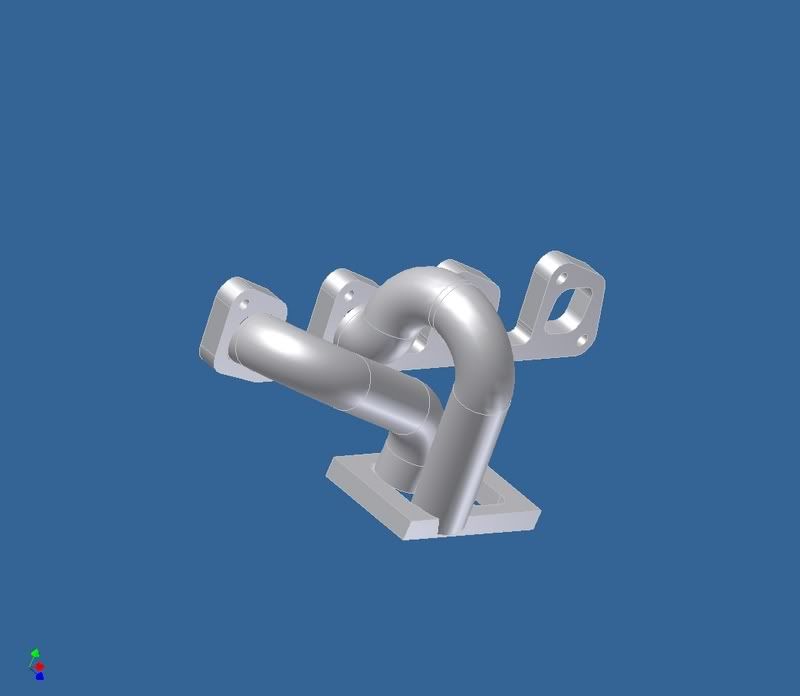

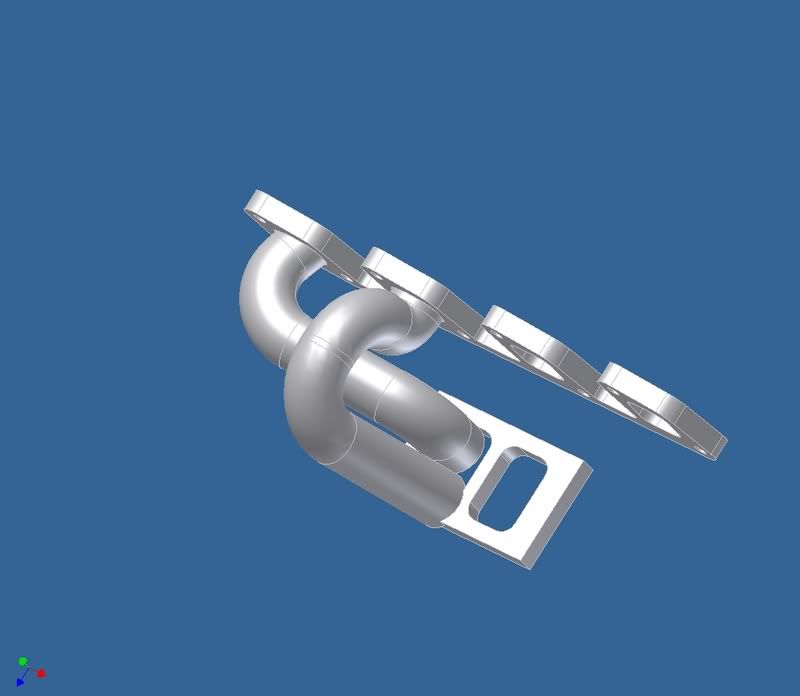

So those who know me have known for quite awhile I've been planning something for my 9. Namely, a holset, a header and a few other goodies. Well here are pics of the semi-complete header. The collector was somewhere around the shop, but Miles was out at work today, so I just went in and snapped a few pics. Anyway, check it out. Purty isn't she!