as stated before, car went to go-autoworks for the intercooler piping and dump tube fabrication, and it got wrapped up saturday around noon.

in progress

compressor wheel and welded cover

cold side piping

tagged up

hot side stuff

gate

accentuating the superclear(tm) turnsignal

dat stance

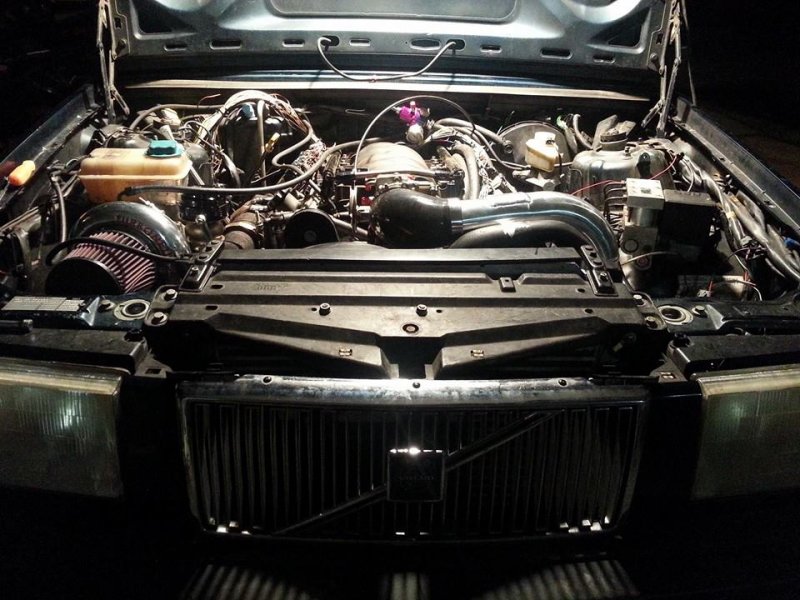

filtered and grilled up

pool's clean too, just gotta wait for it to warm up.

Busy weekend, couple of issues had to be worked out, some I don't understand, some that do make sense, and some that were pre-existing and I just got around to addressing them. First a list, (so I can remember myself) and then an explanation if needed-

power steering line r&r, had a pinhole in the weld, should be good to go now. Comically long time to correct this due to packaging constraints.

return line at pan was loose and oozing, tightened that up

Crank and cam input circuit upgrade

downpipe wrappage

transmission stuff

So, crank and cam input circuit stuff-- I don't know when the brain trust decided to re-name the VR inputs as "universal" inputs and then wave healing hands for all types of inputs and let it ride, while consolidating documentation and reducing instructions down to "adjust pots until it works". That's bull**** on a number of different levels and reckless to boot. Having tried that before (on this car with the previous setup), I can say without a doubt not all proposed solutions work as advertised and they choose to ignore the ones that don't. Aggravating, but I suppose it is what it is. Almost all management systems have their hangups, some are worse than others, this is a fairly minor issue for most people I would imagine and reasonably easily rectified (simply bought the dual input board from jbperf, hooked it up, and things worked right off the bat), but frustrating none the less. With this in place, I reached over, cranked the car in wasted spark mode, worked flawlessly (previously using the onboard hall/optical input it would occasionally fail to sync on cranking and lose sync at low speeds). switched to sequential and it sync'd and lit right off. Yay.

Transmission stuff.. I could probably write a book about this. I will keep the big part short: I hate cork pan gaskets. That **** never seems to seal no matter how clean and how tight I install it. My tailshaft leak appears to have been fluid coming out of the pan and getting blown around. It may still ooze out the tailshaft a little, but the major leak was from the back of the pan. All of the pan bolts that were installed I guess after getting things warm a time or two, had gotten a little loose (some more than others, and one was missing entirely), so I dropped the cross member (needed to space the trans up some more anyway), tightened all of the bolts again, replaced the missing mother****er, and hosed it all off with brake cleaner. I'll look later today and see if the puddle is back, or if I dodged a drain pan removal bullet.

Tuning the transmission has been interesting to say the least, it's almost as much fun as I thought it would be, and definitely more aggravating than I thought (but of course, we have a tendency to wax poetic about new things prior to jumping in). The initial tune worked reasonably well but wouldn't kick down at almost any speed for any reason. This made for some interesting initial rough-in tuning. I got creative with the datalog and re-mapped the shift tables... and overshot on a couple of things. An assumption that I didn't need to get into OD prior to 50mph was a bad idea, and, incidentally, if your downshift numbers are higher than your upshift numbers, it won't shift into that gear at all.

Lockup hysteresis is another area that will require attention, there have been found to be places where the converter locks and unlocks fairly rapidly, which also has an interesting feel to it.

And then there appears to be a leakdown issue, which I'll have to research a bit.. if started cold, it has been the norm that the transmission works fine. If, however (and this is not a hard and fast rule...) it's been driven around and then parked for a little while, it seems to go into a 'limp mode', however all of the inputs on the microsquirt work and it seems to think it's behaving correctly. It seems that after a few minutes and/or jacking with the selector, it gets the air out of whatever leaked down and starts working again. I don't know if this is temp related or leak related, on one or two occasions I've gotten it remedied by adding fluid (although it wasn't low enough that it should have affected low speed driving). when it's working though, it shifts like a BEAST. I'll have to play with the line pressure values to tone some of that down or it's going to beat the bearings out of the diff. WOT 1-2 shift at 6500 rpms, 3psi, it steps out. any more power and when it hits that shift it's going to switch to rolling burnout (not that this was really unexpected).

As far as manners, it's nice. The package is heavier than the 16v+aw71, as the front end is sitting now an inch or two lower (almost on the bump stops), I suspect most of the weight difference is from the 200+lb transmission, but the total weight of the engine, turbo, accessories is also probably 100lbs more than the volvo setup was. cruises effortlessly (as expected) and for the moment, the 5psi spring (not the 7 as initially thought) means it's making just over what it would have were it completely NA (it doesn't get to 5psi, and it doesn't stay there, much closer to 3.5-4psi and tapering on down to just over 3psi in the upper rpms) right now, it's quiet everywhere except idle of all places, and at idle it sounds like a pickup with flowmasters or something on it (so as long as I can stop at lights with trucks, no one will suspect the volvo...)

still ironing details, but it's coming along.

, nicely done.

, nicely done.