<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27287596711/in/dateposted/" title="Judson Supercharger 1"><img src="https://c8.staticflickr.com/8/7396/27287596711_e21a0f9de0_b.jpg" width="1000" height="716" alt="Judson Supercharger 1"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

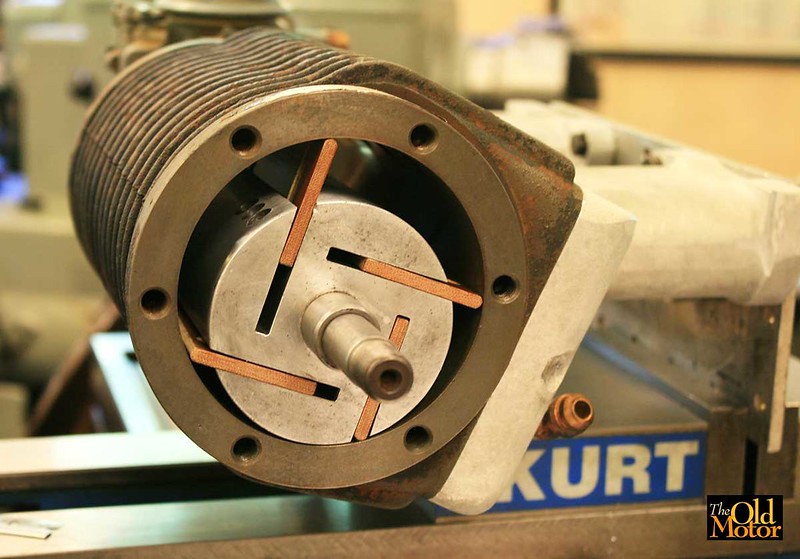

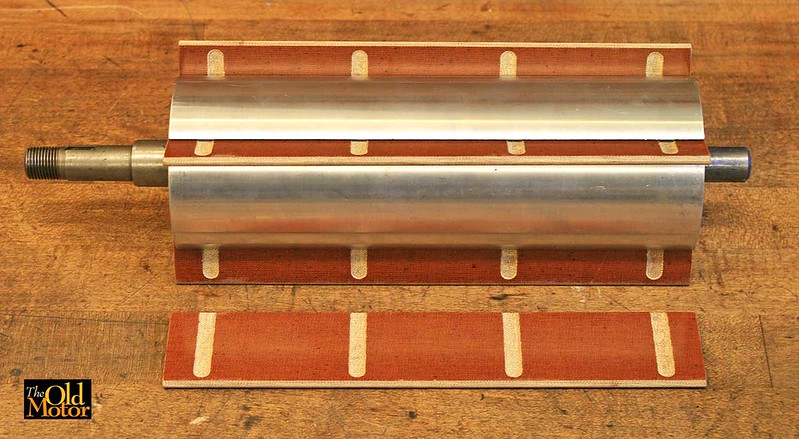

I have been to busy with customers cars lately, but managed to clean up all of the Judson Supercharger parts and give it a good inspection. I bought it all apart but it is 99% complete and is only missing a few common fasteners. It only needs a routine rebuild with new bearings, seals, and gaskets, but I will need to machine a new set of fiber vanes for it which is not that big of a deal.

This set of photos gives you a very good idea of how it is constructed and what all of the parts look like. To get a better idea of how it all works take a look at the

first post in this thread which explains it.

This pales in comparison to the modern turbos and controls many of you are installing, but is going on a 1968 122s Wagon (the shop truck) that is being modified with only bolt on high performance vintage pieces from the 1960s and early-1970s. When installed (takes 3-4 hrs) on a stock engine with no other changes it is capable of a 30% HP increase and the engine should put out about 150 HP with the added 6-7 psi boost.

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27358159615/in/photostream/" title="Judson Supercharger 2"><img src="https://c8.staticflickr.com/8/7476/27358159615_c174c4aa6f_b.jpg" width="1000" height="671" alt="Judson Supercharger 2"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/26751751843/in/photostream/" title="Judson Supercharger 3"><img src="https://c4.staticflickr.com/8/7059/26751751843_bd0e457c5b_b.jpg" width="1000" height="872" alt="Judson Supercharger 3"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The carburetor is a simple one-barrel Holley unit that was used on 220 ci six cylinder cars and trucks in the 1950s and early sixties that is more than big enough for the 108.5 ci B18. It is not very sophisticated (in fact with the glass float bowl it looks like a toilet mechanism), but will serve well after a rebuild to get the system set up and running and have a base line to compare to future changes.

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/26750702114/in/photostream/" title="Judson Supercharger 4"><img src="https://c3.staticflickr.com/8/7445/26750702114_d5727e3a9d_b.jpg" width="1000" height="770" alt="Judson Supercharger 4"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27358183645/in/photostream/" title="Judson Supercharger 5"><img src="https://c6.staticflickr.com/8/7059/27358183645_4c86672104_b.jpg" width="1000" height="702" alt="Judson Supercharger 5"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/26384206164/in/dateposted/" title="jud"><img src="https://c5.staticflickr.com/8/7054/26384206164_2aabc5c301_b.jpg" width="809" height="221" alt="jud"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27287658791/in/dateposted/" title="Judson Supercharger 6"><img src="https://c8.staticflickr.com/8/7561/27287658791_a50526ac07_b.jpg" width="1000" height="830" alt="Judson Supercharger 6"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27324812456/in/photostream/" title="Judson Supercharger 7"><img src="https://c1.staticflickr.com/8/7195/27324812456_c266c1d18b_b.jpg" width="1000" height="738" alt="Judson Supercharger 7"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27358202135/in/photostream/" title="Judson Supercharger 9"><img src="https://c8.staticflickr.com/8/7512/27358202135_01f13d7a34_b.jpg" width="1000" height="827" alt="Judson Supercharger 9"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The drive end of the aluminum rotor and shaft. The rotors were precision balanced at 10K RPM.

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27260500492/in/photostream/" title="Judson Supercharger 10"><img src="https://c5.staticflickr.com/8/7303/27260500492_0f0c982118_b.jpg" width="1000" height="679" alt="Judson Supercharger 10"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>

The crank and blower pulleys.

Below is all of the original throttle linkage, the belt, the blower lubricator, and even the air cleaner.

<a data-flickr-embed="true" href="https://www.flickr.com/photos/68431219@N02/27260532772/in/photostream/" title="Judson Supercharger 12"><img src="https://c5.staticflickr.com/8/7356/27260532772_c7b5a747c8_b.jpg" width="1000" height="692" alt="Judson Supercharger 12"></a><script async src="//embedr.flickr.com/assets/client-code.js" charset="utf-8"></script>