msggrunt -

this is a truly impressive and inspirational post. very nice attention to detail.

as for the leather seat covers' fitment issue, i've installed several factory replacement leather covers on various cars at the dealership (mostly due to insurance claims) and can tell you, even in those as recent as 2018 models, when they're first hog-ringed and strapped on, they look about as tight and neat as a well-worn catchers mitt. especially the two-pieces-fit-everything rear seat jobs. fellas who've been doing it decades longer than myself advise that there's little to be done other than letting humidity and the sun run their coarse to draw things up.. unless you have a steam machine handy.. i've heard of such-equipped upholsterers who can work magic to tighten leather up, but i've yet to witness it, so can't give much insight.

this is all concerning factory-born leather, though, and it sounds like the lseat leathers are substantially thicker. but leather's leather, right? i can't blame you for pampering this babe, but i think a couple weeks out of the garage and baking in some sun would go a long way in giving your seats a little face-lift. also worth noting: for any customer who initially scoffed at their new-yet-puckered covers, we tell them what to expect, the nature of the beast, and to bring it back in a month if they're still unhappy, and i've yet to experience a single comeback on the issue.

as for the armrest fitment: it looks like a loose sock, and that's also common where leather covers meet these fixtures. it's also less susceptible to the atmospheric resolve bc of decreased surface/breathable area.

to tame these areas, mist the leather with clean (DISTILLED) water and either allow it to absorb or massage it in (depending on water penetrability/waxiness) followed by several minutes under a hair dryer (low is normal, medium is max, NOT a heat-gun,) and finally lightly massage again (with gloved hands) to assist seating and form of leather as it cools around the fixture. this is, i presume, the manual way to accomplish what the upholstery wizards do with their steam wands.

i didn't get a great look at the arm rest's stitching, but i've seen instances of upholstery that made me scratch my head and kinda wince when it's on the work bench, but then fit the bill nicely once it was installed and taut, so it might be worth a shot if you haven't started the return/rebuild process.

hey, speaking of the sun, how do you think that interior paint would hold up to exposure?.. say, on a daily driver that doesn't get garaged much other than free parking on the (occasional) weekends downtown? do they make any claims as to longevity long-term sun exposure conditions?

gotta be honest, when i read your comment about the new leather smell in the car, my first thought: how can he smell it with all the spray paint?! haha.. did it take a long time to dissipate? like i said, daily driver, but on the plus, power windows work, so i could stand wide open ventilation til summer hits at least..

testpoint -

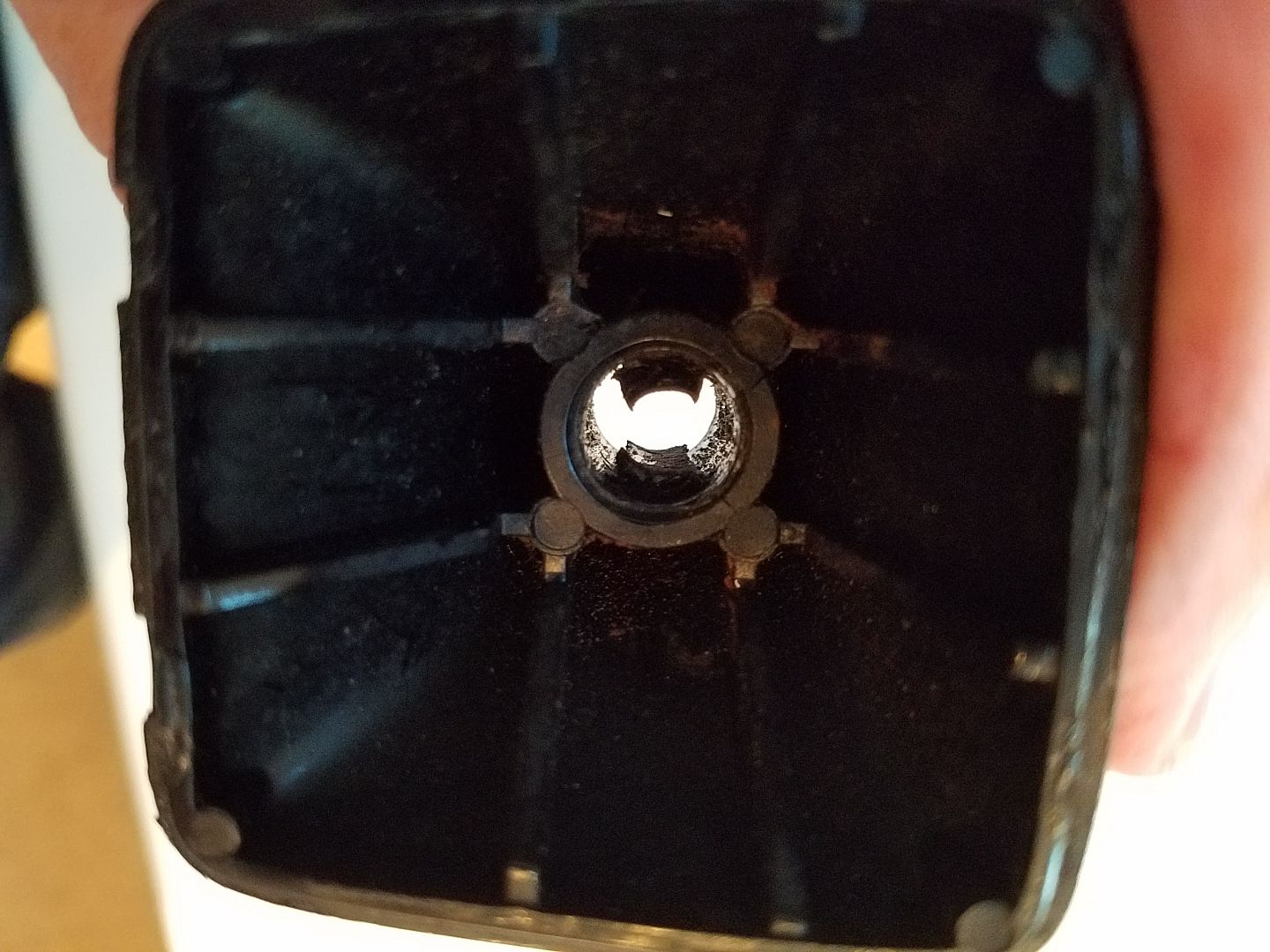

it's been a while since my automatic was totalled. M47 now fills her shoes, but i did have the wonderful opportunity to go digging for my slice o the pie safety switch during that brief love affair. i seem to recall the only thing holding the shifter knob on was some sort of friction/pressure fitting inherent to the knob itself..

so you basically have to knock it off from the bottom side using blunt force. i don't recall what size wrench is called for, but essentially one whose open end is wide enough to fit around (cradle) the metal shaft of the shifter lever, but small enough that it doesn't pitch and mar the bottom/sides of the knob when you knock it with a hammer. before knocking the knob off the shaft, grab the OD button with some pliers and pull it out/disconnect the wires. with the jaws of the wrench cradling the metal shaft, raise until the sides of the jaws are resting against the underside of the shift knob. take a hammer and tap upwards on the bottom/opposite side of the wrench until the knob pops up/off. it's helpful to wrap the knob/button in a shop towel or plastic baggy, as the button and a spring will shoot out of the knob once they disengage from the internals of the shaft if they aren't secured/contained within the knob. hopefully you've found an answer/solved your issue before now, but just in case.