volvowagoon

Active member

- Joined

- Jul 19, 2012

- Location

- Franklin, IN

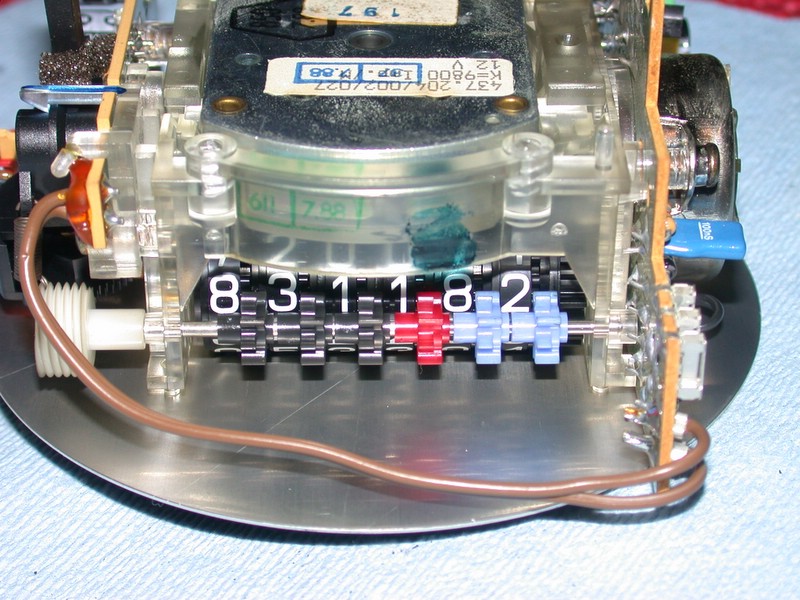

It could be there's a whole new category of odometer failures originating in mechanical issues within the number display wheels due to debris, breakage, or previous owner monkeying. You are the pioneer in documenting it if you find the culprit.

Do you have any experience with removing the number wheels from these later clusters? It looks like a pretty sealed unit to prevent tampering.

Since it got warmer outside the issue has been happening a lot less often which may be a total coincidence. I'm probably done trying to fix it unless somebody can help me perform some bench tests. I have a function generator at work I can use to simulate speed, multimeters, process meters, soldering irons, and a lot of other nifty tools at my disposal. I just don't exactly know what to do with them!

Since it got warmer outside the issue has been happening a lot less often which may be a total coincidence. I'm probably done trying to fix it unless somebody can help me perform some bench tests. I have a function generator at work I can use to simulate speed, multimeters, process meters, soldering irons, and a lot of other nifty tools at my disposal. I just don't exactly know what to do with them!

Maybe then I'll be able to look into this a little further. I guess the point of the update was more or less an attempt to formulate a game plan that I'll execute later.

Maybe then I'll be able to look into this a little further. I guess the point of the update was more or less an attempt to formulate a game plan that I'll execute later.