aight. so here's the setup:

They don't come a whole lot more stock than this, the only "mods" it has are.. no cat (wasn't me), and the egr system is ****ed up so I blocked it off at the intake. Even the hot air intake was still hooked up until I needed to move it for the dyno's optical pickup.

I was troubleshooting some other stuff initially (and fixing things as they came up). Very first pull was 77 whp, running very poorly. After running some stuff through, I ended up replacing the oxygen sensor (still not 100% sure that it's acting completely right, but I think there's other stuff going on right now) with one off the parts 244, things cleaned up a little. Fixed a trans leak, did a couple runs to let the ecu sort itself out, played with cruise control (Works... sort of, think it's got a leak still somewhere), and tried to get as much of the year-old 82 octane out. Then I added 5 gallons of fresh 93, and it was a different car entirely.

So, that's where this story begins:

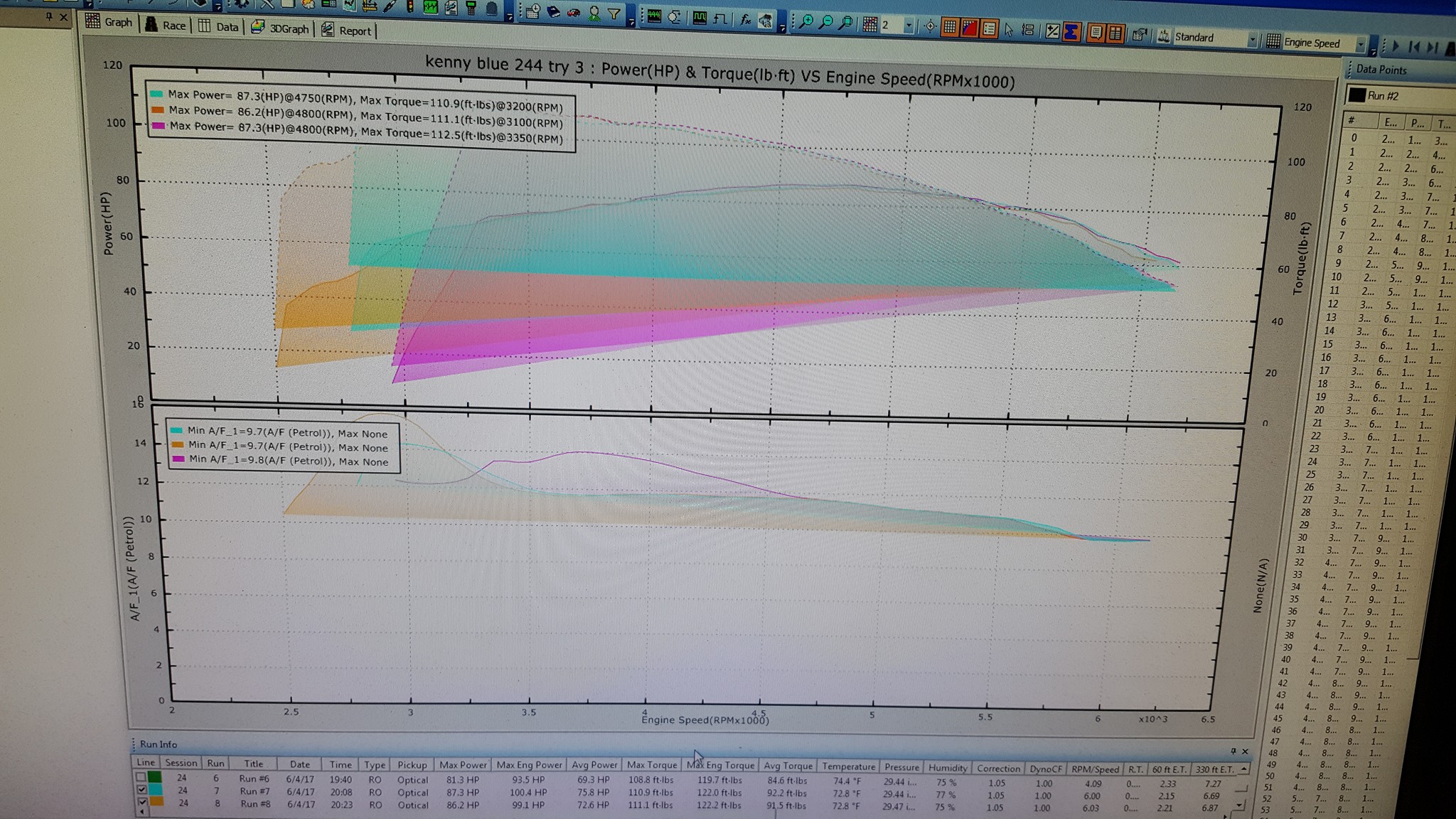

First pull on the graph (run 7) was after letting it idle for a few minutes (where it finally leaned out into the 12's at idle, suspect knock enrichment is to fault for some of that), everything was up to temp already. the mechanical fan never fully engaged before, during or after the pull

Second pull was minus the shroud and mechanical fan. I will say this about the mechanical fan on the car.. either it's leaked out and garbage, or conditions in the room didn't warrant it engaging. The car never indicated any kind of overly warm running condition, so, it could go either way. I would guess the unloaded weight of the unit to be a couple of pounds. The car *sounds* like it rev's easier without the fan on. Car was off (obviously) for the removal of the fan, would estimate 10 minutes or so. other fans in the shop were blowing around the car.

Third pull was minus the mech fan, and with the top of the airbox open and filter pushed out of the way (i.e. simulating some sorta high-flow intake or whatever). More intake noise, sounded throatier, aaannnddd... that was about it.

Statistically, I'd say all were a wash. The biggest (and least of a surprise) change I got out of the car was getting better gas in it.

From a performance perspective, in the summer with the a/c on, I'd wager the E-fan helps a noticeable amount esp off of idle vs an engaged mechanical fan. Once you get going, it's likely to disengage and not be a big problem. It does take up a lot of space, however, and I have not noticed any substantial problems with the swap. YMMV.

going forward, I'm going to play with the LH/ezk setup on the car and see if I can get it to do better (and ignore the o2 sensor for the time being), esp up top even though the ol M cam is past dead up 'air