-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

YASVT (Yet Another Sixteen Valve Turbo) - now 16V Whiteblock (LS)

- Thread starter JohnMc

- Start date

I'm really not sure I'll be able to remove/replace the transmission with the motor installed. I've been putting it on and off currently with no flywheel/clutch/pressure plate, not even a pilot bearing, So it really needs just an inch or slightly less clearance before the input shaft goes in the hole and it slides forward. The whole trans is pretty long, and the engine doesn't lean back very much (perhaps I should look at why?) - I'm not thinking it would work if I had to slide it out several inches to clear a clutch.

- Joined

- Jul 16, 2009

- Location

- Monterey/Falun

If you loosen the engine mounts you can tilt the engine back pretty far

- Joined

- Jul 27, 2008

- Location

- Dallas, TX

If you loosen the engine mounts you can tilt the engine back pretty far

and drop the front cross member an inch or two.

- Joined

- Jul 16, 2009

- Location

- Monterey/Falun

and drop the front cross member an inch or two.

I never had to do that. But I'm sure it would help. With the 6speed I loosened the mounts. With the 80e I don't touch anything

- Joined

- Aug 8, 2006

- Location

- Sherbrooke, Qc

This is the exact Poly mount that will be available to purchase with the CD009 adapter I make, it line up perfectly with the trans mounting point and is cheaper than the stock "axial" cd009 mount. I just ordered a batch of 10 of them so they can be shipped together!

It really is a big transmission where it split in two right at the end. I hope the fit in a 7/9 will be a bit forgiving.

It really is a big transmission where it split in two right at the end. I hope the fit in a 7/9 will be a bit forgiving.

- Joined

- Jul 27, 2008

- Location

- Dallas, TX

I never had to do that. But I'm sure it would help. With the 6speed I loosened the mounts. With the 80e I don't touch anything

Im anticipating this to pull out my 4l60e to change out the torque converter.

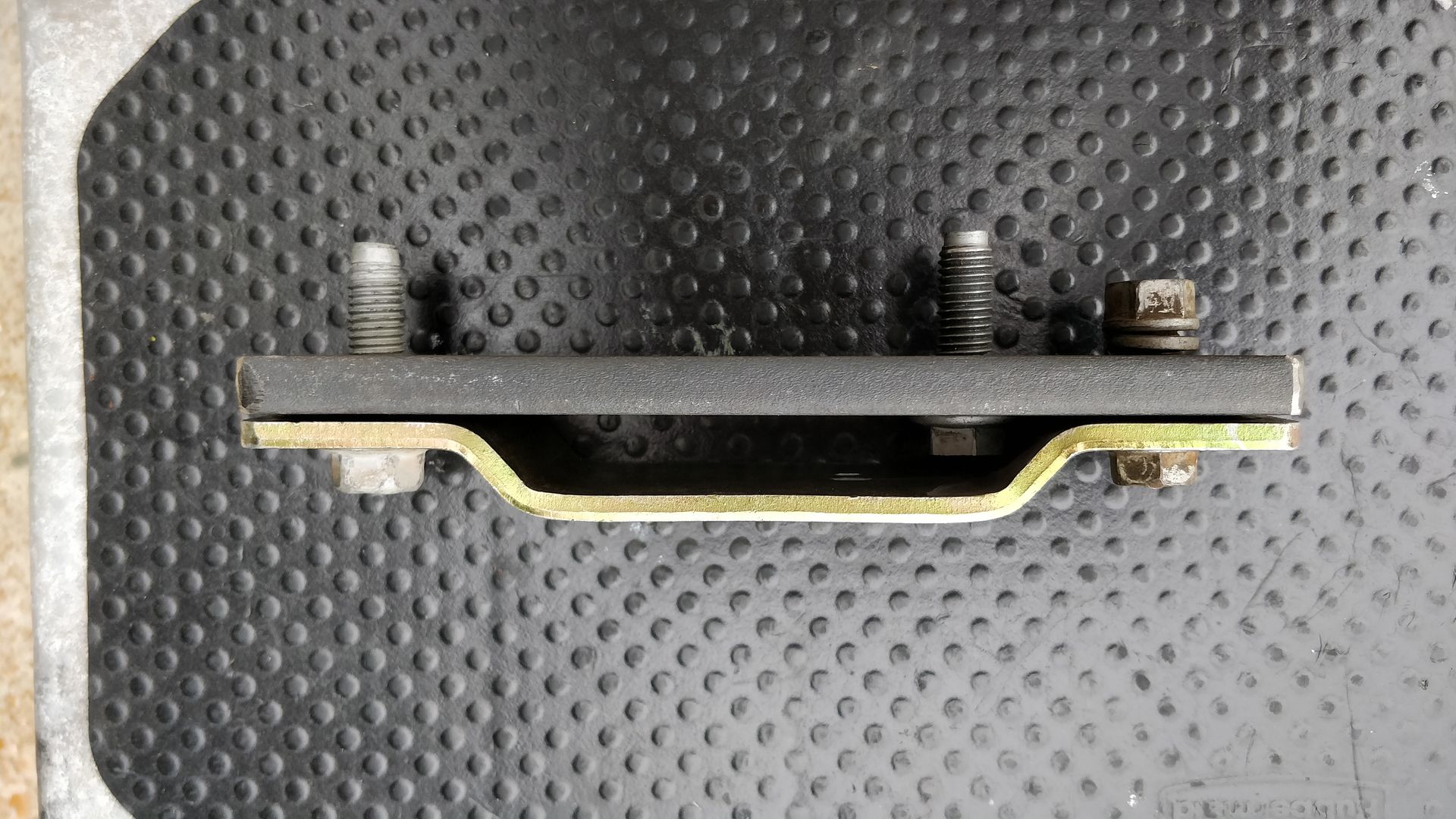

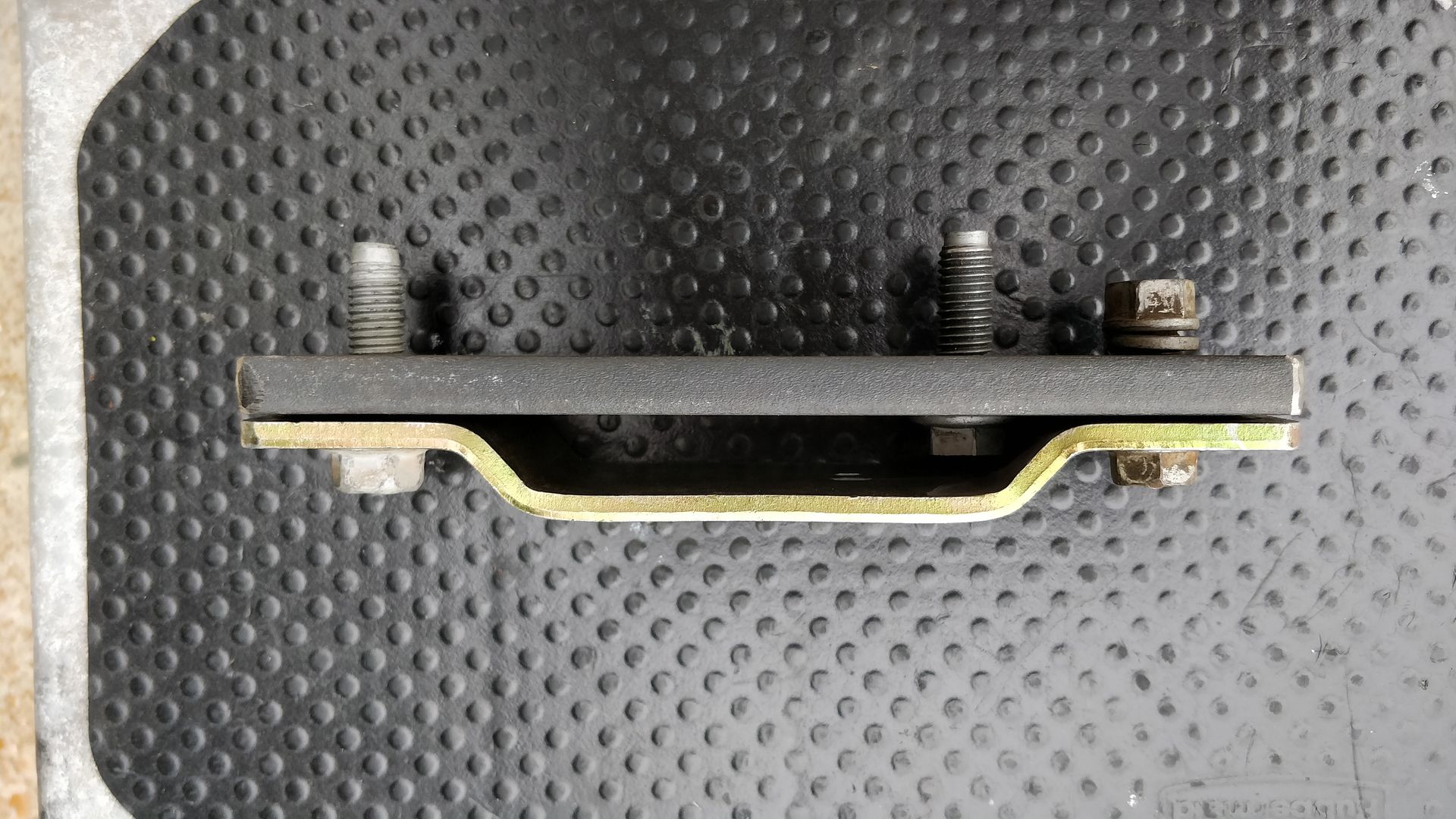

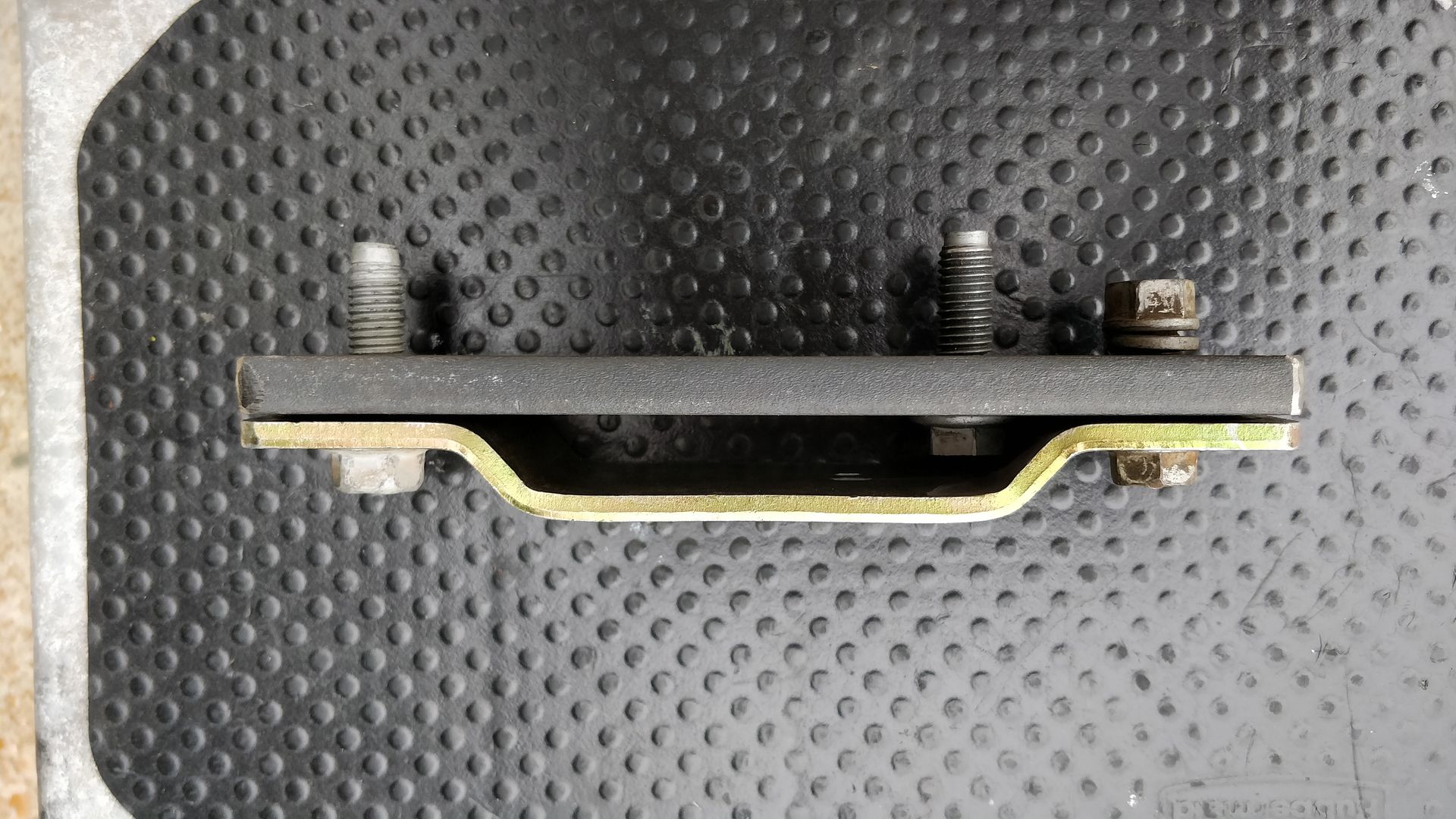

After weeks of CAD design and hours of exacting machine work, here's my super intricate transmission mount:

Yeah, it's a solid chunk of metal (2X.25) with 3 holes drilled in it. One bolt goes through the T5 mount and the chunk of metal into the trans. The next one (middle bolt) just goes through the chunk into the trans, and the last one just bolts the T5 mount to the chunk.

The whole T5 mount isn't shown, just the top part.

I could have found a mount that would fit to the CD009 directly, but it wouldn't have centered properly on the T5 crossmember. For better or worse, the T5 is off center, and it just happens to sort of match up to the CD009 on one side.

Easy, cheesy, on to other things.

Yeah, it's a solid chunk of metal (2X.25) with 3 holes drilled in it. One bolt goes through the T5 mount and the chunk of metal into the trans. The next one (middle bolt) just goes through the chunk into the trans, and the last one just bolts the T5 mount to the chunk.

The whole T5 mount isn't shown, just the top part.

I could have found a mount that would fit to the CD009 directly, but it wouldn't have centered properly on the T5 crossmember. For better or worse, the T5 is off center, and it just happens to sort of match up to the CD009 on one side.

Easy, cheesy, on to other things.

DET17

Reformed SAABaholic

- Joined

- Nov 1, 2009

- Location

- NW Georgia

Yeah, it's a solid chunk of metal (2X.25) with 3 holes drilled in it. One bolt goes through the T5 mount and the chunk of metal into the trans. The next one (middle bolt) just goes through the chunk into the trans, and the last one just bolts the T5 mount to the chunk.

Adapto-magic! TB loves simple solutions......

BTW, M.H.Yount sectioned part of his 240 crossmember out and modified it to "bolt in" so he could pull his T5 with engine in situ, for clutch work. I'm sure he has photo records of those changes.

The T5 was easy to pull. Just take off the 4 bolts holding it to the adapter plate, and pull it back. Cross member, shifter, driveshaft removed, of course. But no struggling with those bell housing bolts.

It remains to be seen how easily the CD009 comes out. It's got a lot less wiggle room.

It remains to be seen how easily the CD009 comes out. It's got a lot less wiggle room.

M.H. Yount

Active member

- Joined

- Nov 1, 2008

- Location

- Charlotte, NC

Getting tranny out has, in my experience, always been a piece of cake. Getting it back in -- especially if the disc/pressure plate has been monkeyed with --- not so much.

DET - engine x-mem cut was primarily so I could, by myself, easily pull engine/tranny combo for fab purposes during the swap. With tight points around clutch arm, exh manis and oil pan -- needed some clearance somewhere to manage the hoist/angles alone. I think I had it in/out 10-11 times during clean up and fab. If I had only clutch work to do at this point - I'd likely just drop tranny and do it from the bottom.

DET - engine x-mem cut was primarily so I could, by myself, easily pull engine/tranny combo for fab purposes during the swap. With tight points around clutch arm, exh manis and oil pan -- needed some clearance somewhere to manage the hoist/angles alone. I think I had it in/out 10-11 times during clean up and fab. If I had only clutch work to do at this point - I'd likely just drop tranny and do it from the bottom.

Last edited:

MadDog_945

Våga Vägra 8V

- Joined

- Apr 25, 2006

- Location

- Lower Saxony

After weeks of CAD design and hours of exacting machine work, here's my super intricate transmission mount:

Yeah, it's a solid chunk of metal (2X.25) with 3 holes drilled in it. One bolt goes through the T5 mount and the chunk of metal into the trans. The next one (middle bolt) just goes through the chunk into the trans, and the last one just bolts the T5 mount to the chunk.

Easy, cheesy, on to other things.

Awesome..!!! May I have the drawings?

Heh, I didn't even measure anything, I just eyeballed it.

Trans came out again yesterday, waiting for the new top mount shifter.

I'm going to pluck the engine out tonight and start tweaking (bashing) the passenger inner fender, some small love taps on the right header (motor mount clearance) and the crossover tube (sway bar clearance).

I pondered that downpipe fitment a little bit, and just decided that all it needs is a less bulky connecter between the upper and lower sections. It all fits quite nicely, there's just a v-band clamp in an awkward spot. I'm thinking all I need to do is cut off the v-bands and use a band clamp:

That way it removes almost all the bulk and size of the v-band clamp, without me needing to heavily rework anything. I might just need to weld a small section of 3" tubing on to fine tune the fit.

Trans came out again yesterday, waiting for the new top mount shifter.

I'm going to pluck the engine out tonight and start tweaking (bashing) the passenger inner fender, some small love taps on the right header (motor mount clearance) and the crossover tube (sway bar clearance).

I pondered that downpipe fitment a little bit, and just decided that all it needs is a less bulky connecter between the upper and lower sections. It all fits quite nicely, there's just a v-band clamp in an awkward spot. I'm thinking all I need to do is cut off the v-bands and use a band clamp:

That way it removes almost all the bulk and size of the v-band clamp, without me needing to heavily rework anything. I might just need to weld a small section of 3" tubing on to fine tune the fit.

After a week or two if inaction on this, I spent a while yesterday. Pulled the motor out and spent a while bumping, yanking, thumping, bashing, grinding, bending. Fixing all the small fitment issues. Then stuck the motor back in. It all looks the same, but now nothing is touching that shouldn't be.

Still waiting on the top mount shifter to arrive.

Futzed around with various power steering lines I had laying around (240, 740, 940) and while they all screw right into the GM steering pump, the clearance between the bracketry and the pulley at the engine is very exacting. After a while I decided to just skip trying to make something work with the 3 pressure lines I had and got a couple of adapters - GM Corvette (it's snug) to 6AN adapter, and an M14X1.5 banjo to 6AN adapter, and a 6AN hose. Won't look cheesy, no stacked adapters, everything fits straight on, nice generic hose - just two female 6AN fittings on each end.

Yeah, that's all I have to show for the last couple of weeks.

Still waiting on the top mount shifter to arrive.

Futzed around with various power steering lines I had laying around (240, 740, 940) and while they all screw right into the GM steering pump, the clearance between the bracketry and the pulley at the engine is very exacting. After a while I decided to just skip trying to make something work with the 3 pressure lines I had and got a couple of adapters - GM Corvette (it's snug) to 6AN adapter, and an M14X1.5 banjo to 6AN adapter, and a 6AN hose. Won't look cheesy, no stacked adapters, everything fits straight on, nice generic hose - just two female 6AN fittings on each end.

Yeah, that's all I have to show for the last couple of weeks.

LC4CARL

Aero challenged

- Joined

- Sep 8, 2008

- Location

- Vancouver, WA

And months from now you?ll catch glimpse of some detail you nailed and smile.

poulrais

Well-known member

- Joined

- Sep 8, 2006

- Location

- Quebec, CAN

Where did you order the top mount shifter?

CBF Performance.

http://cbfperformance.net/?~~id=70985258&~~mode=product

Even the shortest ones that hang off the rear are not going to fit very well into a 240. Even with the engine scooted an inch and a quarter forward from where the STS mounts placed it.

This will be a bit too far forward, might need to trim the shifter hole slightly, and use the extension on the lever to move it a couple of inches to the back.

http://cbfperformance.net/?~~id=70985258&~~mode=product

Even the shortest ones that hang off the rear are not going to fit very well into a 240. Even with the engine scooted an inch and a quarter forward from where the STS mounts placed it.

This will be a bit too far forward, might need to trim the shifter hole slightly, and use the extension on the lever to move it a couple of inches to the back.

- Joined

- Nov 12, 2002

I am watching this Nissan trans adventure as an alternative to the t5 planned for mine.

poulrais

Well-known member

- Joined

- Sep 8, 2006

- Location

- Quebec, CAN

Did you receive your shifter?