New year, goals have changed a bit.

The last semester went pretty well, so good I'll get a nice amount of scholarship which can be dumped into the brown to pass MOT.

Also worked on a few cars for buddy's buddies and earned a bit money. I did a V6 Ford Mondeo alternator "swap" and I achieved a new level - calmness when there is sooo little place for my hands to work. I was so proud of myself when I finally turned the key, it worked flawlessly.

Next one was a Nissan Vanette rust job, was quite ****ty but did it in 5 days and those new pieces will surely outlive the van. And by outlive, I mean the owner already did second fenderbender with it today...

Also helped the company my brother works for with my Inventor knowledge. It is not funny to repair a loosely 3D scanned plastic box, but it came out great.

Onto the 244: new goal is to finish the main bodywork before or in summer. As you may seen it has 022 on its plates, and somehow I'm also 22. It HAS to run this year.

The left side is 90% done, only the wheelarch needs to get welded on. That only happens a few days before I seal and paint the floor.

Shimmed the commando, and threw on the "new" rubber sealing thingy on top of it. It looooks sooo nice already

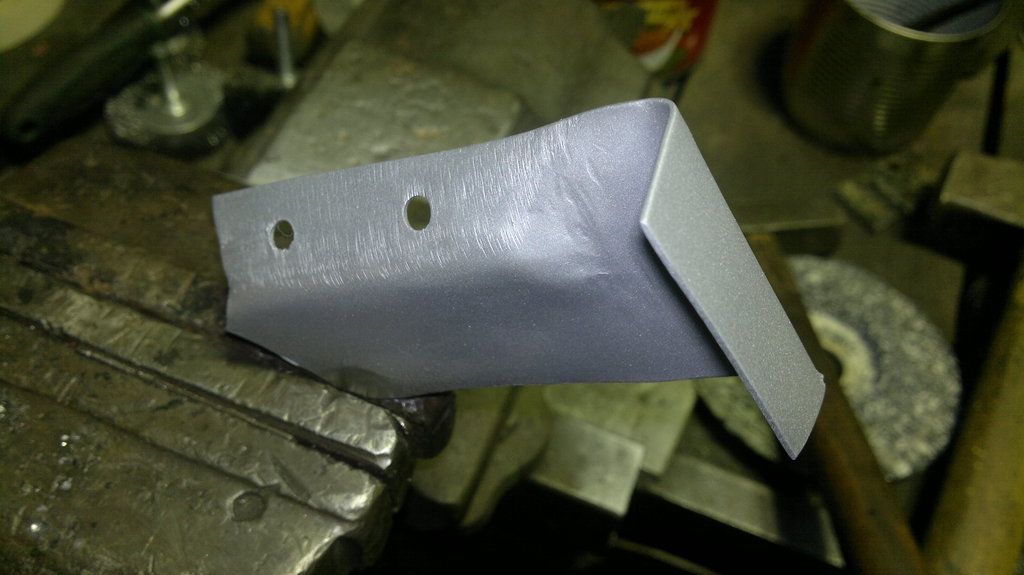

Notice the repaired quarter-spare wheel well joint. There is NO overlap.

Right side came (january 28) and by a weird idea I chained the front strut to the ground and jacked the A pillar.

Sadly I've had no routine in crash jobs, so I did so much unneeded and harmful pushing-pulling on this chassy before and I'm glad I sorted it all out with this last step.

Gaps came out pretty nice, not perfect by any means but I can live with it. Doors mostly seal, and overall it looks nice. Only the front door needs four 2mm thick shims, and thats it.

This pumped me to cut away all the not needed rusty pieces down there. I already fabbed the lower inner sill and welded it on. I hope I can get the floorboards connected to it this weekend.

Also snow fell and I did a quick tuneup on the beige donor car. Funny thing I put the brown's SU carb on it, and it ran quite ****ty. No wonders, SU carbs need dampening oil in them. The brown's carb did not have ANY atf oil in it. I have no idea how I was able to cruise with it on petrol. It even felt stronger than LPG.

So right now it starts on first try:

https://www.dropbox.com/s/vaof8txbubn2ojq/2016-01-06-1467.mp4?dl=0

Looks exactly like my work.