pwaes

New member

- Joined

- Mar 22, 2009

- Location

- Zeg ik niet

Just got my MOT (in Dutch APK) so she is again allowed on the road (legally) since 2 years, good times!

But now the following has occured, engine so far:

b230ft

531 ported - flowed

ck1 camshaft

siemens deka 660cc injectors

90+ manifold ported

t04e turbo

full 3 inch with v-band exhaust

m90 gearbox

stock intercooler (npr on the way, i know)

tloa chips, ezk and ecu

Picks up from 2200 rpm to 0.9 bar (so 13 psi) untill around 5200 rpm and then goes banana's (upwards 2 bar/ 28 psi) untill the redline of 6500 rpm which I have not reached because I don't keep flooring it.

Is this the famous boost creep I am experiencing? The turbo should be capable of this kind of hp/boost with relative ease.

But now the following has occured, engine so far:

b230ft

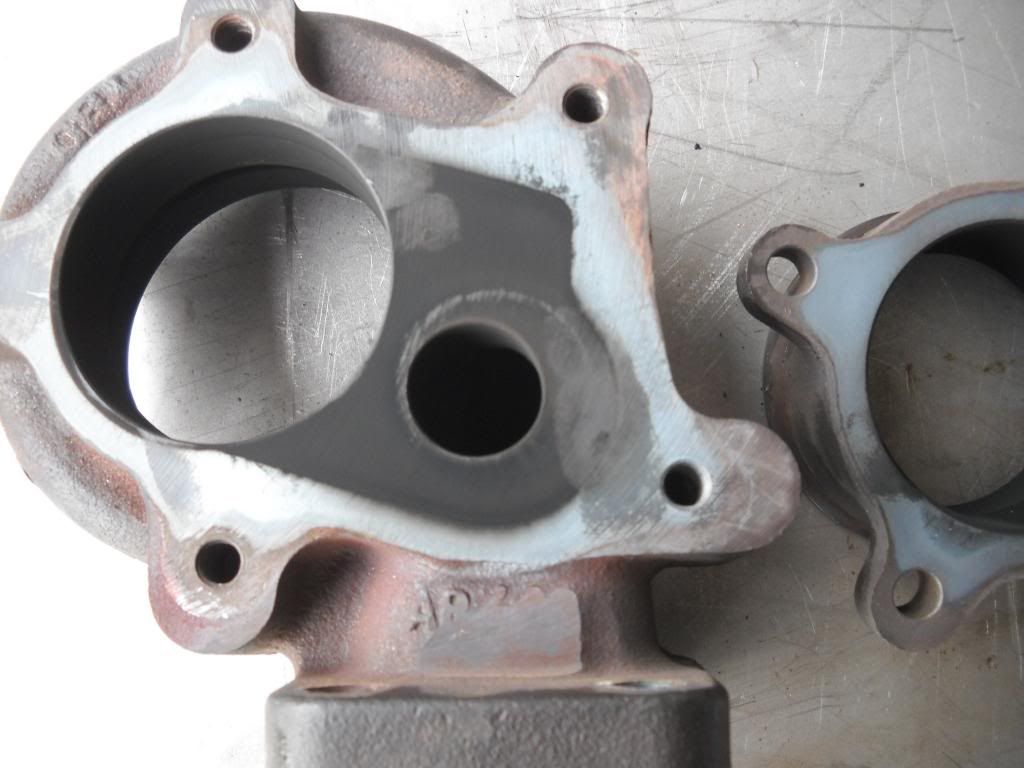

531 ported - flowed

ck1 camshaft

siemens deka 660cc injectors

90+ manifold ported

t04e turbo

full 3 inch with v-band exhaust

m90 gearbox

stock intercooler (npr on the way, i know)

tloa chips, ezk and ecu

Picks up from 2200 rpm to 0.9 bar (so 13 psi) untill around 5200 rpm and then goes banana's (upwards 2 bar/ 28 psi) untill the redline of 6500 rpm which I have not reached because I don't keep flooring it.

Is this the famous boost creep I am experiencing? The turbo should be capable of this kind of hp/boost with relative ease.