Sorry for confusion - I change my plan and don't want to change chips in b234f - now I want small +TIs there any place when i can download or buy only tuned bin file ?

-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel/Spark tuning for LH 2.4/EZK with TunerPro!

- Thread starter beepee

- Start date

AFR adjustment closed loop

hello i have just started using tunerpro and oustrich 2.0 to my old Volvo

the reason is that i think modern clear bensin contains more oxygen to burn cleaner and then the old LH dont understand that it need to lean out to get the same AFR as when the car was new.

its no way this car did 15l/100km when it was new at come driving

anyway the problem it when i adjust main fuel map it seems like the ecu want to compensate back to its goal at 14.7

i could turn off the closed loop option but then i could be better out with a carburator!

i have read a bit about this but can not find a fix.

there is a few videos on youtube where it seems like a homemade program do the adjustment of the AFR / Lanbda value but the programs is nowhere to be found

Do anyone have a plugin for tunerpro where its possible to change this?

or a XDF for my Bosch 934 ecu where AFR is included?

thanks a lot

hello i have just started using tunerpro and oustrich 2.0 to my old Volvo

the reason is that i think modern clear bensin contains more oxygen to burn cleaner and then the old LH dont understand that it need to lean out to get the same AFR as when the car was new.

its no way this car did 15l/100km when it was new at come driving

anyway the problem it when i adjust main fuel map it seems like the ecu want to compensate back to its goal at 14.7

i could turn off the closed loop option but then i could be better out with a carburator!

i have read a bit about this but can not find a fix.

there is a few videos on youtube where it seems like a homemade program do the adjustment of the AFR / Lanbda value but the programs is nowhere to be found

Do anyone have a plugin for tunerpro where its possible to change this?

or a XDF for my Bosch 934 ecu where AFR is included?

thanks a lot

Last edited:

Ipdown made a checksum plugin for tunerpro, it can be found on the lh wiki

hello do you have a link for this download? i cant find it

surre_sprett

New member

- Joined

- Oct 24, 2008

- Location

- Namsos - N-Tr?ndelag - Norway

hello i have just started using tunerpro and oustrich 2.0 to my old Volvo

the reason is that i think modern clear bensin contains more oxygen to burn cleaner and then the old LH dont understand that it need to lean out to get the same AFR as when the car was new.

its no way this car did 15l/100km when it was new at come driving

anyway the problem it when i adjust main fuel map it seems like the ecu want to compensate back to its goal at 14.7

i could turn off the closed loop option but then i could be better out with a carburator!

i have read a bit about this but can not find a fix.

there is a few videos on youtube where it seems like a homemade program do the adjustment of the AFR / Lanbda value but the programs is nowhere to be found

Do anyone have a plugin for tunerpro where its possible to change this?

or a XDF for my Bosch 934 ecu where AFR is included?

thanks a lot

One solution for this is to use an Innovate LC1 or 2 wideband lambda and program the analog narrowband output to a different value and feed it to the ECU in place of the stock lambda.

One solution for this is to use an Innovate LC1 or 2 wideband lambda and program the analog narrowband output to a different value and feed it to the ECU in place of the stock lambda.

takk for svar

i got a wideband with a narrowband output,

so i was thinking, if i had an output from the ecu to tell the load 0-10v or 4-20ma or others

then it could be feeded in to a small circuit that manipulate the narrow band according to load

do anyone know if its possible to get a output from the calculated load of the engine?

takk for svar

i got a wideband with a narrowband output,

so i was thinking, if i had an output from the ecu to tell the load 0-10v or 4-20ma or others

then it could be feeded in to a small circuit that manipulate the narrow band according to load

do anyone know if its possible to get a output from the calculated load of the engine?

just found the load signal

Tq/Load signal (to EZK)

anyway do someone know what signal that is given here?

to know how to use the signal for a lambda manipulator

just found the load signal

Tq/Load signal (to EZK)

anyway do someone know what signal that is given here?

to know how to use the signal for a lambda manipulator

so not so much peoples in to this LH2.4 stuff anymore is it?

anyway had a look at the load signal today on my osyloscope,

its a square wawe PWM signal at about 2.4KHZ

dutycycle i could not measure but i got the length of the pulse maybe someone can calculate the dutycycle,

length of pulse at idle: 90us

length of pulse at trottle (may not be full load): 416us

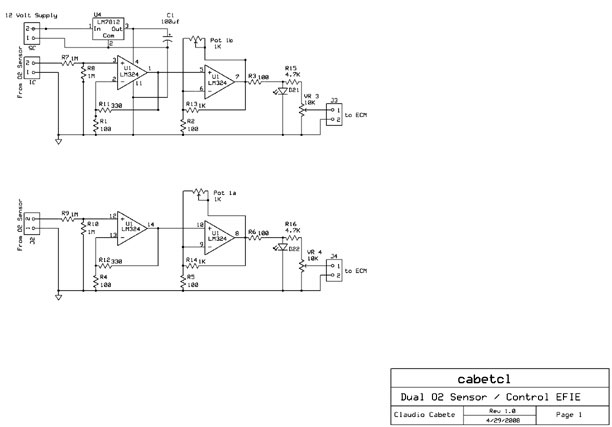

could anyone modify this circuit to be controlled from the load PWM?

i want to have:

-only one part of this circuit is needed cos i got only 1 o2 sensor

-an pot for how much the signal is enhanced at max duty cycle

-an pot for how much the signal is enhanced at min duty cycle

-linear enhancer values between this 2 pots according to load dutycycle

-pot for adjusting dutycycle input if my measurements is not correct

more about this circuit: http://hydrogengarage.com/DIY/DIYinstructions.html

mrjaybeeze

Team Jetronic.info

- Joined

- Feb 2, 2008

- Location

- Norway

jau

Hi there

I can't see how this is going to work ?

The output going to the EZK (ignition) is just an indicator to the ignition box of what kind of load the engine is having and this signal is mainly a result of what is sensed by the MAF in relation to rpm etc

YS

Jens B

Hi there

I can't see how this is going to work ?

The output going to the EZK (ignition) is just an indicator to the ignition box of what kind of load the engine is having and this signal is mainly a result of what is sensed by the MAF in relation to rpm etc

YS

Jens B

Hi there

I can't see how this is going to work ?

The output going to the EZK (ignition) is just an indicator to the ignition box of what kind of load the engine is having and this signal is mainly a result of what is sensed by the MAF in relation to rpm etc

YS

Jens B

higher load requires lower AFR to prewent knocking if the AFR is allways as close to knocking as possible to save fue

thats why i want to enhance the O2 sensor acording to load and modify fuel map accordanly to the afr wanted, and ecu can confirm its at 1 volt but adjusted by anhancer and load signal

this way ecu can maintain in closed loop longer and go to open loop just at the areas that is not cowerd by enhancer

i got a wideband O2 sensor that output full wideband at narrowband signal

so when AFR at lets say 12 is needed by fuel map, then load signal is picked up by the enhanser then offsets the O2 signal by a given adjustable amount to make it 1 volt and the ECU can see 1 volt and fine tune acording to this 1 volt, if it need to tune too much according to the expectations of the fuel map it will trigger check engine lamp and get the too lean or too rich error i belive

im also looking at the knock signal that is going to the LH from the EZK at #4 i wonder if this output anyway if its used at the LH or not. maybe a audorino or other IC could do it all and also keep the AFR close to knocking all the time. if an audorino is used it may eaven have a self learning funktion that make it predict knock based on load engine temp air temp and so on

what kills a engine is:

knocking

high exhaust temperatures

if this is safe then nothing major will happen, exept maybe sparkplugs worning out

i found this circuit a few years back that can sence knock but the circuit have to be tuned to the frequency of the engine http://www.msextra.com/forums/viewtopic.php?f=67&t=36089&sid=eedfba56883e0946625687b8e628d64e&start=100

anyway if there is an output for knock at the EZK it would be a lot easyer to use that one

i also posted on a circuit forum but no answer yet

http://forum.allaboutcircuits.com/threads/need-help-with-circuit-ecu-controlled-o2-sensor-enhancer.118827/#post-939782

why all dis troubble?

-the old volvo uses too much fuel with the modern etanol mixed and structure changed fuel

-i want to slide around sideways in my old volvo!

-i dont want to change to engine from a modern car yet bechause new engines is made from poor materials and is worn out just in 200000km

-its interesting to modify stuff

Last edited:

JW240

All idiot, no savant

- Joined

- Aug 15, 2004

- Location

- The Netherlands, Europe

How much is too much? My 240 easily gets 10L/100km, when I care I can get it down to 8L/100Km.

I'd get a wideband with programmable output and use that. Coupled with right mapping it could work as you want?

I'd get a wideband with programmable output and use that. Coupled with right mapping it could work as you want?

How much is too much? My 240 easily gets 10L/100km, when I care I can get it down to 8L/100Km.

I'd get a wideband with programmable output and use that. Coupled with right mapping it could work as you want?

Mine used 15/100km before i changed my fuelmap and turned closed loop off. Now i dont know yet but its a lot less.

anyway now its not optional cos the ecu drive only by fixed maps that means its more to save and more power to get.

programmable output is not enough from wideband cos the widrband dont know the load of the engine. This way is to keep the ecu in closed loop and adjusting after what the ecu think is 1 volt but in reality its the correct value needed for a spesifick load .

Bechause the ecu want to have 1volt at the o2 sensor at any case exept at open loop

but i want to be in closed loop to have optional fuel consubtion and power. Afr change slightly by air pressure air temperature air moisture oxygen levels in the air and so on, the o2 sensor give a signal back to the ecu to explain what just come out the exhaust and in closed loop the ecu compensate and make the mix "perfect" at 1 volt in the 1990's

times changes and so do the fuel and the programmed afr is no longer good

5ft24

New member

- Joined

- Apr 11, 2014

- Location

- Washington

Ok. Been doing lots of reading...

tons of info to digest. have a 1990 740T, 967 ECU. Auto trans.

Runs good, no ping I can hear, running 92 octane.

My long term plan is to upgrade to a 16T turbo with the 15G conical exhaust housing, NPR intercooler and 3" DP/Exhaust.

Am I better off starting to tweak on the 967 bin I have, or is there a different bin to tune that will better meet the needs of my long term goals?

Thanks

tons of info to digest. have a 1990 740T, 967 ECU. Auto trans.

Runs good, no ping I can hear, running 92 octane.

My long term plan is to upgrade to a 16T turbo with the 15G conical exhaust housing, NPR intercooler and 3" DP/Exhaust.

Am I better off starting to tweak on the 967 bin I have, or is there a different bin to tune that will better meet the needs of my long term goals?

Thanks

5ft24

New member

- Joined

- Apr 11, 2014

- Location

- Washington

umm... Narrowband Lambda sensor is 0-1 volt. 1 volt is rich, 0 is lean. ECU looks for crossings from rich to lean at approx 0.5v for stoich. No Lambda sensor knows the engine load, wideband or narrowband. Only the amount of O2 in the exhaust.

if you tune the tables so the O2 is always showing 1 volt, you are pig rich and washing your cylinder walls with fuel

if you tune the tables so the O2 is always showing 1 volt, you are pig rich and washing your cylinder walls with fuel

Mine used 15/100km before i changed my fuelmap and turned closed loop off. Now i dont know yet but its a lot less.

anyway now its not optional cos the ecu drive only by fixed maps that means its more to save and more power to get.

programmable output is not enough from wideband cos the widrband dont know the load of the engine. This way is to keep the ecu in closed loop and adjusting after what the ecu think is 1 volt but in reality its the correct value needed for a spesifick load .

Bechause the ecu want to have 1volt at the o2 sensor at any case exept at open loop

but i want to be in closed loop to have optional fuel consubtion and power. Afr change slightly by air pressure air temperature air moisture oxygen levels in the air and so on, the o2 sensor give a signal back to the ecu to explain what just come out the exhaust and in closed loop the ecu compensate and make the mix "perfect" at 1 volt in the 1990's

times changes and so do the fuel and the programmed afr is no longer good

sergitin34

New member

- Joined

- Dec 23, 2009

- Location

- Winnipeg MB

Sorry to hack in,I need some orientation.

First: 1989 240 Sedan B230F *(N/A and Stock).

Bosch LH Jetronic 2.4 engine managment.

ECU 0 280 000 951 (made in spain)

ICU: 0 227 400 146 (pink lable) (made in germany)

Tranny: AW70

I have been 4 days reading all the threads regarding to chips with upgrade ROM for N/A and turboed Redblocks Volvos. It called my atention at the end of the read that the guys developing and selling are not doing it anymore.

My questions would be, whom should I ask for info about this in this forum?

Is there any more developed ROM now than these chips Fredrik (frpe82) was selling? I mean they sound like something really good to get your hands on. Since I started reading this thread from the very begining and then hooked up with the other threads including the N/A chipping one. But have now like 8 tabs open and a mess of info.

I still have to open my EZK to check if it is chipable, then if not I would need to buy one that is or a daughter board kit to solder into my motherboard, as I understand it.

Whom is now doing this kinda daughter boards kits?

Then more into this thread topic... Since it seams this chiping interfase has been more friendly now to the rest of us. Is it easier now days buyins an Ostrich emulator and a chip burner device and a couple blank burnable chips, then just upload the right .bin into the chip and go with it? Are Fred's chips ROMs out there for grabs or for buying? Or even simpler, is any one still selling these kits with Fredrik's ECU and ICU chip kit for N/A engines around?

I want to Play too. Please any info would be well regarded.

Thanks and Happy new year.

First: 1989 240 Sedan B230F *(N/A and Stock).

Bosch LH Jetronic 2.4 engine managment.

ECU 0 280 000 951 (made in spain)

ICU: 0 227 400 146 (pink lable) (made in germany)

Tranny: AW70

I have been 4 days reading all the threads regarding to chips with upgrade ROM for N/A and turboed Redblocks Volvos. It called my atention at the end of the read that the guys developing and selling are not doing it anymore.

My questions would be, whom should I ask for info about this in this forum?

Is there any more developed ROM now than these chips Fredrik (frpe82) was selling? I mean they sound like something really good to get your hands on. Since I started reading this thread from the very begining and then hooked up with the other threads including the N/A chipping one. But have now like 8 tabs open and a mess of info.

I still have to open my EZK to check if it is chipable, then if not I would need to buy one that is or a daughter board kit to solder into my motherboard, as I understand it.

Whom is now doing this kinda daughter boards kits?

Then more into this thread topic... Since it seams this chiping interfase has been more friendly now to the rest of us. Is it easier now days buyins an Ostrich emulator and a chip burner device and a couple blank burnable chips, then just upload the right .bin into the chip and go with it? Are Fred's chips ROMs out there for grabs or for buying? Or even simpler, is any one still selling these kits with Fredrik's ECU and ICU chip kit for N/A engines around?

I want to Play too. Please any info would be well regarded.

Thanks and Happy new year.

sergitin34

New member

- Joined

- Dec 23, 2009

- Location

- Winnipeg MB

2 ostriche one laptop?

Hello, I was thinking yesterday if I want to go the emulator way, and want to emulate both chips (ECU and ICU) at the same time, meaning I would get two ostriches emulator in there, could I run them both with the same laptop and one tunerpro? Or would I nee two laptops as well?

I am still learnign the ropes, yesterday started reading ecuprojects and thejetronic website from ipdown as well as other resources.

Thanks.

Hello, I was thinking yesterday if I want to go the emulator way, and want to emulate both chips (ECU and ICU) at the same time, meaning I would get two ostriches emulator in there, could I run them both with the same laptop and one tunerpro? Or would I nee two laptops as well?

I am still learnign the ropes, yesterday started reading ecuprojects and thejetronic website from ipdown as well as other resources.

Thanks.

sergitin34

New member

- Joined

- Dec 23, 2009

- Location

- Winnipeg MB

My ECU seams to be non stock... then?

OK, checking online i found the stock ECU for my car (1989 B230F) would be a 561, but checking I found a 951 (1993?) there, which is the most upgraded in compatible chips. Today I went further and found my ICU xxx 146 is chipable! So I am just been lucky or is it posible some previous owner was already playing with these, I can say my car moves very nicely, but that coming from a previous single carburetor setup is not really a compliment.

Is there any way I could take a look at the actual software in those chips? Like how can I discover what .Bin or XDF is in the ECU or ICU I am using? I just want to be sure some previous owner has not installed some aftermarket chips there already. Maybe I could tell by the tags on the chips.

Then again, what is the best source to sort out some N/A chips for a B230F stock. I found thelostartof then http://bijlsmatechnicalinnovations.nl/, then beepee has some chips but I dont see anything from him that is N/A. Which of these sources offers re-writtable chips? So if in the future I can find a way to improve them I could do so with emulators software and burner?

I know my car is N/A and most here are T'ed cars, so if by any chance this is not the right thread please forgive me and gimme a hint where to post my thoughts.

Currently reading jetronic.info, ECUprojects and some other sites plus like 10 threads here,

Peace.

OK, checking online i found the stock ECU for my car (1989 B230F) would be a 561, but checking I found a 951 (1993?) there, which is the most upgraded in compatible chips. Today I went further and found my ICU xxx 146 is chipable! So I am just been lucky or is it posible some previous owner was already playing with these, I can say my car moves very nicely, but that coming from a previous single carburetor setup is not really a compliment.

Is there any way I could take a look at the actual software in those chips? Like how can I discover what .Bin or XDF is in the ECU or ICU I am using? I just want to be sure some previous owner has not installed some aftermarket chips there already. Maybe I could tell by the tags on the chips.

Then again, what is the best source to sort out some N/A chips for a B230F stock. I found thelostartof then http://bijlsmatechnicalinnovations.nl/, then beepee has some chips but I dont see anything from him that is N/A. Which of these sources offers re-writtable chips? So if in the future I can find a way to improve them I could do so with emulators software and burner?

I know my car is N/A and most here are T'ed cars, so if by any chance this is not the right thread please forgive me and gimme a hint where to post my thoughts.

Currently reading jetronic.info, ECUprojects and some other sites plus like 10 threads here,

Peace.

umm... Narrowband Lambda sensor is 0-1 volt. 1 volt is rich, 0 is lean. ECU looks for crossings from rich to lean at approx 0.5v for stoich. No Lambda sensor knows the engine load, wideband or narrowband. Only the amount of O2 in the exhaust.

if you tune the tables so the O2 is always showing 1 volt, you are pig rich and washing your cylinder walls with fuel

you clearly dont understand how the ecu works!

the ecu want to keep the average afr at 14,7 ok

to do this the ecu will adjust fuel amount accordingly.

so if the sinewave from the o2 sensor is changed by forexample +100 mv to the orginale signal

the ecu will get back its 14,7 by reducing fuel in to the engine.

when the ecu see 14,7 its actually maybe 15.2 or something.

amyway this is in closed loop. to get the system to work in closed loop at higher load the afr has to be adjustable!

to adjust the afr bechause its not possible to do in the fuelmaps, wee need to do it by chenging the signal in to the ecu from the o2 sensor

thats why it need to be a circuit that will adjust by itself baced on the load of the engine

Hello, I was thinking yesterday if I want to go the emulator way, and want to emulate both chips (ECU and ICU) at the same time, meaning I would get two ostriches emulator in there, could I run them both with the same laptop and one tunerpro? Or would I nee two laptops as well?

I am still learnign the ropes, yesterday started reading ecuprojects and thejetronic website from ipdown as well as other resources.

Thanks.

read the first post please and about the EZK.

you should not care about the ignition

you need only one ostrich 2.0

First: 1989 240 Sedan B230F *(N/A and Stock).

Bosch LH Jetronic 2.4 engine managment.

ECU 0 280 000 951 (made in spain)

ICU: 0 227 400 146 (pink lable) (made in germany)

Tranny: AW70

I have been 4 days reading all the threads regarding to chips with upgrade ROM for N/A and turboed Redblocks Volvos. It called my atention at the end of the read that the guys developing and selling are not doing it anymore.

My questions would be, whom should I ask for info about this in this forum?

Is there any more developed ROM now than these chips Fredrik (frpe82) was selling? I mean they sound like something really good to get your hands on. Since I started reading this thread from the very begining and then hooked up with the other threads including the N/A chipping one. But have now like 8 tabs open and a mess of info.

I still have to open my EZK to check if it is chipable, then if not I would need to buy one that is or a daughter board kit to solder into my motherboard, as I understand it.

Whom is now doing this kinda daughter boards kits?

Then more into this thread topic... Since it seams this chiping interfase has been more friendly now to the rest of us. Is it easier now days buyins an Ostrich emulator and a chip burner device and a couple blank burnable chips, then just upload the right .bin into the chip and go with it? Are Fred's chips ROMs out there for grabs or for buying? Or even simpler, is any one still selling these kits with Fredrik's ECU and ICU chip kit for N/A engines around?

I want to Play too. Please any info would be well regarded.

Thanks and Happy new year.

only golden collor ezk kan be chipped, the other have the maps in the cpu, aso explained here http://ipdown.net/jetronic.info/tiki-index.php?page=HOWTO%3A%20EZK%20Tuning

at the ipdown side you can download files for your ecu

here you can buy the tools needed ostrich 2.0 and a chip burner

http://moates.com/

you actually dont need a chip burner bechause you will upload your file to the ostrich and the ostrich will work without the pc, as the chip would normally do

if you just want to chip your brains and dont want to know how it works and how to modify and actually spend time to do all this its easyer just to buy a aftermarked chip its lots out there, but its no warranty that it meets your requirements

5ft24

New member

- Joined

- Apr 11, 2014

- Location

- Washington

you clearly dont understand how the ecu works!

the ecu want to keep the average afr at 14,7 ok

to do this the ecu will adjust fuel amount accordingly.

so if the sinewave from the o2 sensor is changed by forexample +100 mv to the orginale signal

the ecu will get back its 14,7 by reducing fuel in to the engine.

when the ecu see 14,7 its actually maybe 15.2 or something.

amyway this is in closed loop. to get the system to work in closed loop at higher load the afr has to be adjustable!

to adjust the afr bechause its not possible to do in the fuelmaps, wee need to do it by chenging the signal in to the ecu from the o2 sensor

thats why it need to be a circuit that will adjust by itself baced on the load of the engine

I understand exactly how it works, but from your original post, you said the O2 sensor provides 0.5V for rich and 0 for lean. the sensor provides 0-1 volt.

And yes, a 1-1 voltage follower circuit that you can offset + and - will skew what the ECU see's to change A/F.

my comment was about stock ECU and unmodified signal.