- Joined

- Jul 16, 2009

- Location

- Monterey/Falun

I drive around on et streets at about 16psi. That helps the traction a bit

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

I'm just using the Volvo 260 hydraulic master. I checked the size - it's 3/4" bore. Same as the Camaro has with the same T56 clutch slave.

I did double check the sizes. But then I do see people running larger master cylinders (by a little bit - 13/16" or 7/8") for 'performance' shifting on T56's.

The main complaint on the stock GM 3/4" master cylinder seems to be related to a tiny orifice built into it to slow the clutch action down, likely done to help lengthen the drivetrain lifespan.

Actually got a slight bit more work done ion this yesterday. It was a small 'housekeeping' task that needed to be done - replacing the heater control valve. It's been stuck part-way on for a while now. Doing that now because I was putting on a super shiny neat looking STS machining firewall heater hose fitting (the one-piece predecessor to this: https://www.stsmachininginc.com/pro...rewall-port-303-stainless-steel-1975-1993-240 ) - with the engine-side pipes that point to the left away from the LS engine.

Oy vey, that was not a fun task. At all. The heater control valve was clearly not designed to be replaced in the car, since you had to bend several metal things out of the way to get enough room to get it out. Then you had to adjust the cable and fasten a spring clip 98% blind and working through a small opening. All while cramming your body into the driver's side footwell. I think I spent about an hour and a half, two hours wrestling around under there before finishing up.

The old valve's control lever still moved, but the inside part doesn't budge. I bought a replacement kit from IPD a few years ago and just never got around to putting it in.

On the plus side, the kit had instructions for -91 cars that had MANY more steps. Apparently, those used an older style valve that is hard to find these days, the kit basically updated older cars to use the 92+ valve. So I got to skip over half of the steps. Which likely preserved my health and sanity.

On the inside of the firewall heater hose fitting, apparently the 92+ cars have one of the pipes curving downward, and a much shorter hose to the control valve. But the STS firewall part has two short straight hose fittings, the -91 configuration. But since I had this IPD kit, it basically has all the parts to convert from the early style to the later, so I had a correct shaped hose to go from the old (and STS) style fitting to the new style control valve. All's well that ends well.

Now I just need to stick the engine in again and start hooking things up, measure for a driveshaft, order a radiator, order some fuel rails. The LS6 fuel rails seem to fight with the truck coils for position, I figured a simple set of eBay fuel rails would cure that.

I have also decided to just leave the Volvo rear axle in for now, stick the modified Ford 8.8 back in the corner of the garage and deal with that as a separate project. I'll just have my existing T5 one-piece driveshaft shortened a little and get the Nissan yoke on it. I'll deal with keeping the BAS and speedometer working with the Ford's speed sensor later on (something like 136 teeth! Various options on how to deal with that...). And getting a new set of wheels to match the 4.5" bolt pattern.

Oh wow, that's rad. Adding to my notes.I've been meaning to hit up http://www.reluctorrings.com/. I've not had time to do some other measurements but they seem up to the task.

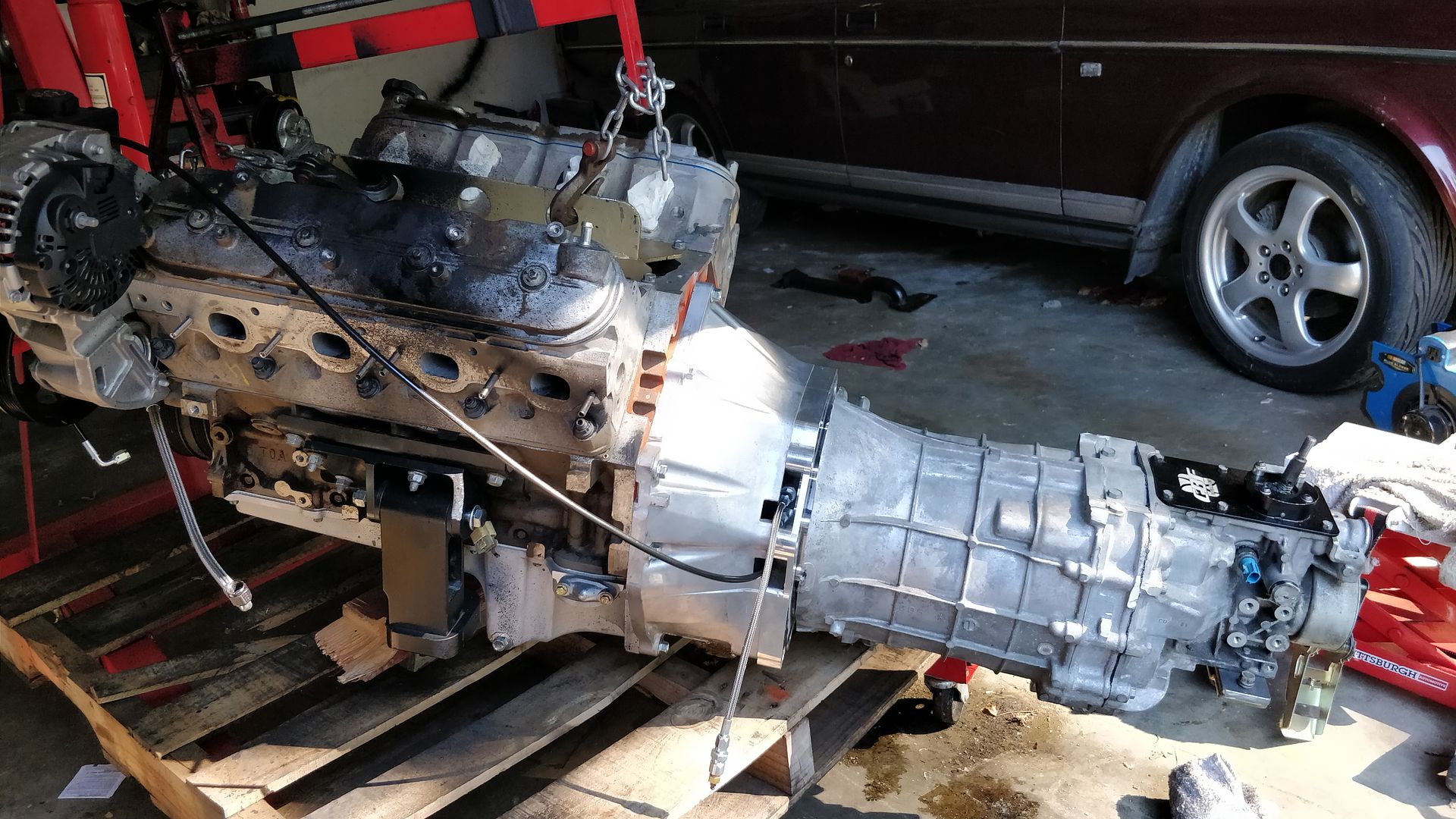

Got slightly motivated this weekend and stuck the motor in the car. I wasn't sure the LS and the CD009 would fit in bolted together, but it wasn't bad. I did have to lift the front of the car a little, and the back of the car a lot, to get it to all work properly, but with a few minor bumps and scrapes, it went in.

made me think about the crazy angles and levering they had to do to wedge the engine and transmission back into a Countach