hi guys,

TLDR: thingtened crackshaft+ untightened rods turns fine/ rods tightened: does not trun what so ever

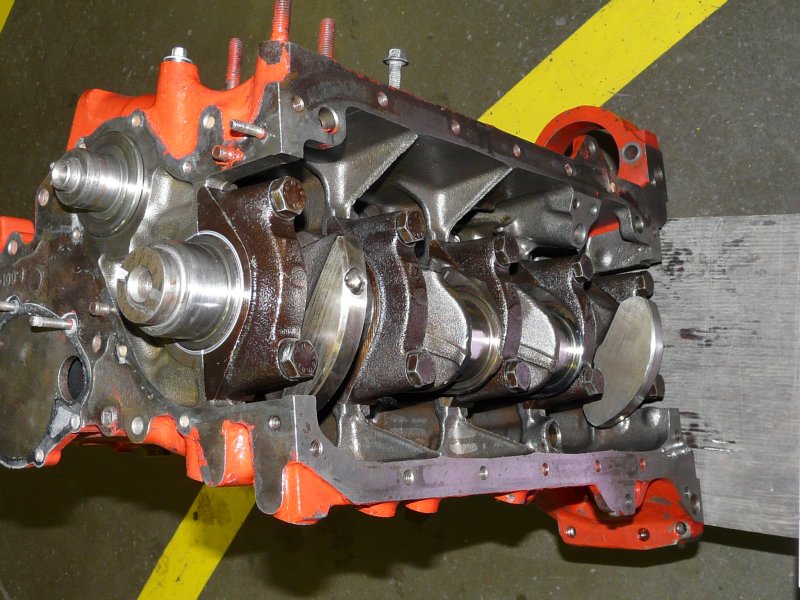

I took a B204GT appart a few years ago, it was running when i started the project, but leaking oil everywhere, woudn't idle popperly,...

I've got som more time now and I'm (re)building it. It's got new rods (had a chance to buy the cheap) and measured everything up so i got the right parts.

Had te crankshaft machined to new specs (as right in between two sizes that they recommend bearings for. Bought new bearings for the crackshaft brackets and the rods. Installed the crackshaft, tightened it to spec and was able to still turn it by hand. Installed rods with the oil rings, and tried turning it over, was a bit harder, but still easy.

Tightend my rods with the ARP 2000 bolts i got with it to the specs on the package.

Tried to turn the engine by hand, nothing, tried to do it wit my smaller wrench, still nothing.

I can set my torque wrench to 180nm and it clicks before my engine starts turning. I haven't tried to put more force onto it.

losened the rods again and it turns freely now.

I used just a bit of motor oil to lube things up (worked fine with the crankshaft alone).

any ideas. I know it's probably wrong bearings for the rods, but i measured the crackshaft and it was exactly the size it needed to be for those bearings. (don't ask me the coreect size, this was done 2-3 years ago) Bought the bearings from volvo. Any chance i got wrong bearings in my package? never measured those, but they seem to fit really nice, the stick to the shaft with a bit of oil perfectly..

TLDR: thingtened crackshaft+ untightened rods turns fine/ rods tightened: does not trun what so ever

I took a B204GT appart a few years ago, it was running when i started the project, but leaking oil everywhere, woudn't idle popperly,...

I've got som more time now and I'm (re)building it. It's got new rods (had a chance to buy the cheap) and measured everything up so i got the right parts.

Had te crankshaft machined to new specs (as right in between two sizes that they recommend bearings for. Bought new bearings for the crackshaft brackets and the rods. Installed the crackshaft, tightened it to spec and was able to still turn it by hand. Installed rods with the oil rings, and tried turning it over, was a bit harder, but still easy.

Tightend my rods with the ARP 2000 bolts i got with it to the specs on the package.

Tried to turn the engine by hand, nothing, tried to do it wit my smaller wrench, still nothing.

I can set my torque wrench to 180nm and it clicks before my engine starts turning. I haven't tried to put more force onto it.

losened the rods again and it turns freely now.

I used just a bit of motor oil to lube things up (worked fine with the crankshaft alone).

any ideas. I know it's probably wrong bearings for the rods, but i measured the crackshaft and it was exactly the size it needed to be for those bearings. (don't ask me the coreect size, this was done 2-3 years ago) Bought the bearings from volvo. Any chance i got wrong bearings in my package? never measured those, but they seem to fit really nice, the stick to the shaft with a bit of oil perfectly..