Got an AWESOMELY packed Cometic HG in the mail from Blubrik in the mail. Srsly cool little wooden packing container:

Thanks! Awesome packing job!

That allowed me to put the head time and start looking at the fitment. And... of course, bane of my life, buying all these random parts and expecting them to fit together.

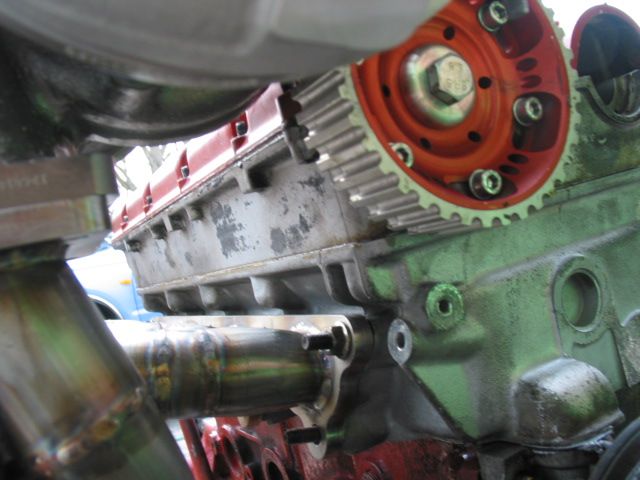

Bolting the manifold directly to the head, and the turbo directly to the manifold... and the turbine housing actually lightly touches the cam gear. That's a little close clearance.

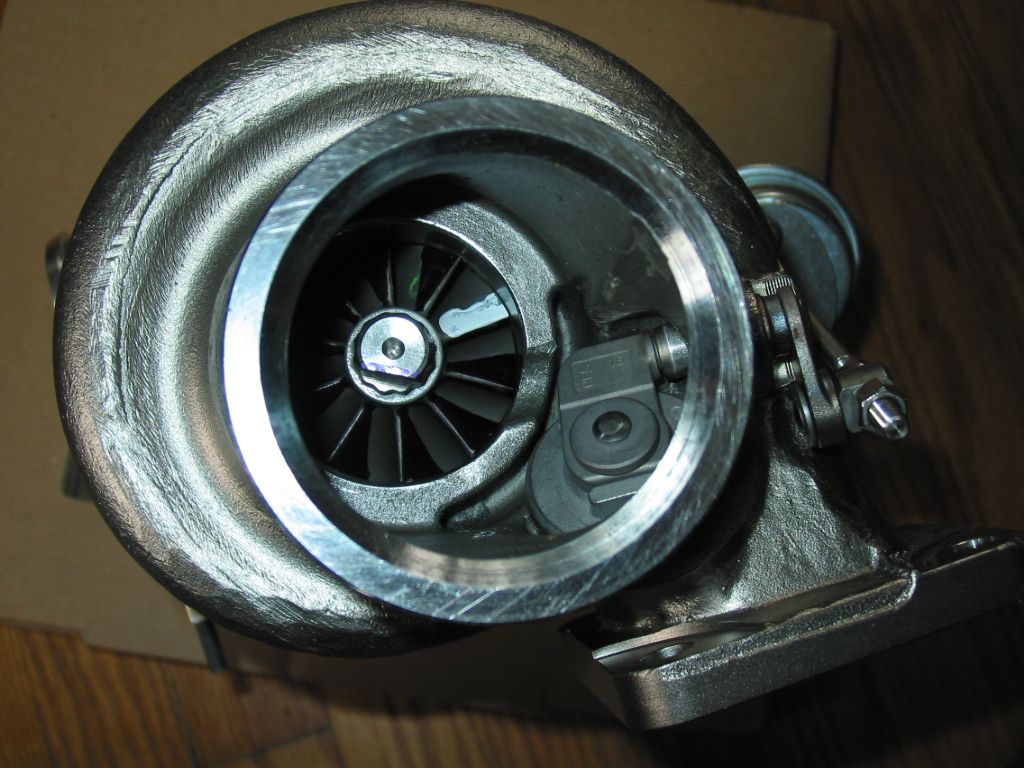

Pondering a cheap, quick, and dirty fix. Get another exhaust flange, maybe some longer studs, and space it over a bit (mocked up with nuts on the exhaust studs). And get another T4 divided flange and use it as a spacer between the manifold and turbo (old T3 flange laying about used as a spacer here):

That nets me a little more clearance, although I still am a little curious how the T-belt will handle hot shutoffs, sitting next to a hot turbine housing. There might be enough clearance for a heat blanket though, def enough for some sort of sheet metal shield as well.

Is this tactic a decent one? Or should I just ship the mani off to someone to have it cut and rewelded to tilt the flange away from the motor some?