Blowbig

New member

- Joined

- Jan 4, 2012

- Location

- Ballard, WA

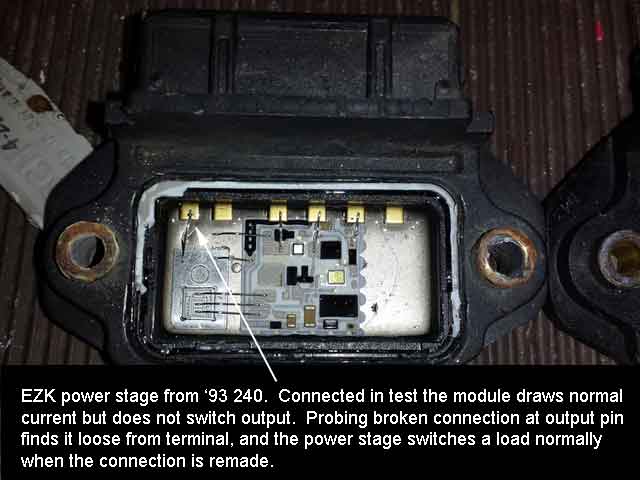

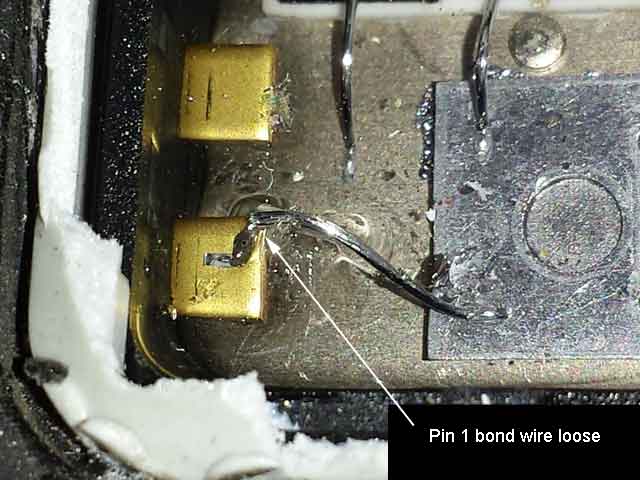

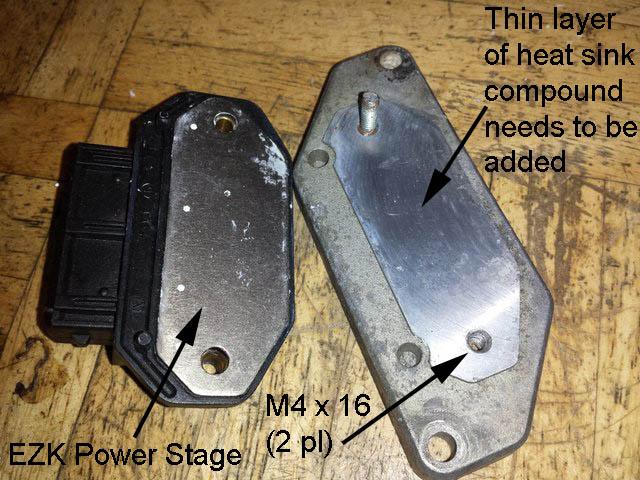

Every couple of years I replace the power stage, FPR, supression relay and CPS for good measure. The new Bosch 0 227 100 124 doesn't come with the "heat conducting paste" anymore. Checked with Worldpac and they opened a few others to see if this one went missing - none of them come with the paste. I was told by an old-timey Volvo tech that that stuff was really important. Anyone know what to use in place of this? Thanks.