Summer and Fall 2016

Since making the 242 operational, overall work and progress slowed down comparatively in the subsequent months. Since the CEL light still mocked me from the instrument cluster, I unplugged the ECU to clear the codes and see how long it took to return. Driving the car for a couple minutes it came back on with the familiar codes of 2-2-1 and 2-3-1. For the next couple of weeks the car did not like starting cold as it would stumble and hesitate especially when going up hills or hard acceleration. Searching and consulting the internet did not turn up anything conclusive. One morning decided to remove the spark plugs to inspect them and see if they show evidence of running lean or rich. Looking at them they were definitely not fouled, but more on the lean-ish side of the spectrum.

Reinstalling the plugs back in I restarted the car and suddenly it idled smoother than it had in a while. After pondering what had just happened, the proverbial lightbulb went off. I realized one of the components I had not changed out this whole time were the ignition wires. Being a set of Bougicords wires, had not thought they would be suspect or needed to be replaced out. Later that afternoon ordered a new set of Bougicords along with a few other parts. Arriving just before July 4th, installed the new wires which resolved the running issue and the CEL light illuminating.

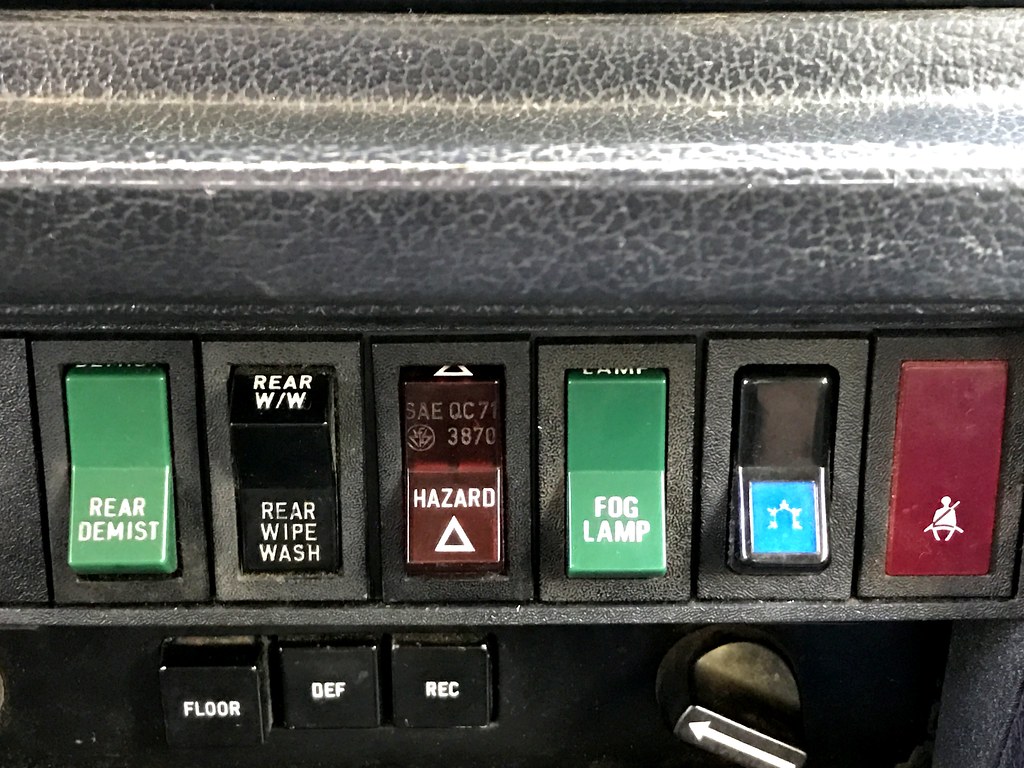

One of the other plans for the 242 involved installing a set of 242GT driving lights and grill. I had all the parts to make the conversion, but I did not know the exact location of where to drill holes for the mounts into the valence. After posing a question on Turbobricks, Highperauto posted with a link to the installation instructions online and two days later the driving lights had been installed and wired up.

http://www.turbobricks.com/forums/showthread.php?p=5431175

In August dug into the front suspension noise. Talking the front wheels off and looking around I checked out the various components. On the passengers’s side while looking at the front strut, noticed the several threads were visible on the strut retaining collar. Using a pair of large channel locks, grabbed the sides and tightened down the collar into the strut tube and the noise disappeared.

During the same period the overdrive started to be contemptuous. It began not able to engage and every so often would work, but most of the time would not. Started by checking the wiring going through the shifter to the push button in the knob, but that looked to be not the issue. After thinking back to the other electronics which failed (ECU and Fuel Injection relay) when trying to initially start the car, dug through the spares to locate another relay. Swapped in a new replacement and the OD now worked on demand. The wet spring and garage environment really did a number on the car.

Added a creature comfort in the form of an armrest between the front seats, the type with the integrated cup holders found in the later 240s. Found one in the junkyard several years back and finally installed it into the car. Since the 1975 does not have the pre-drilled holes in the transmission tunnel, had to use that type instead of the more common rectangular armrest.

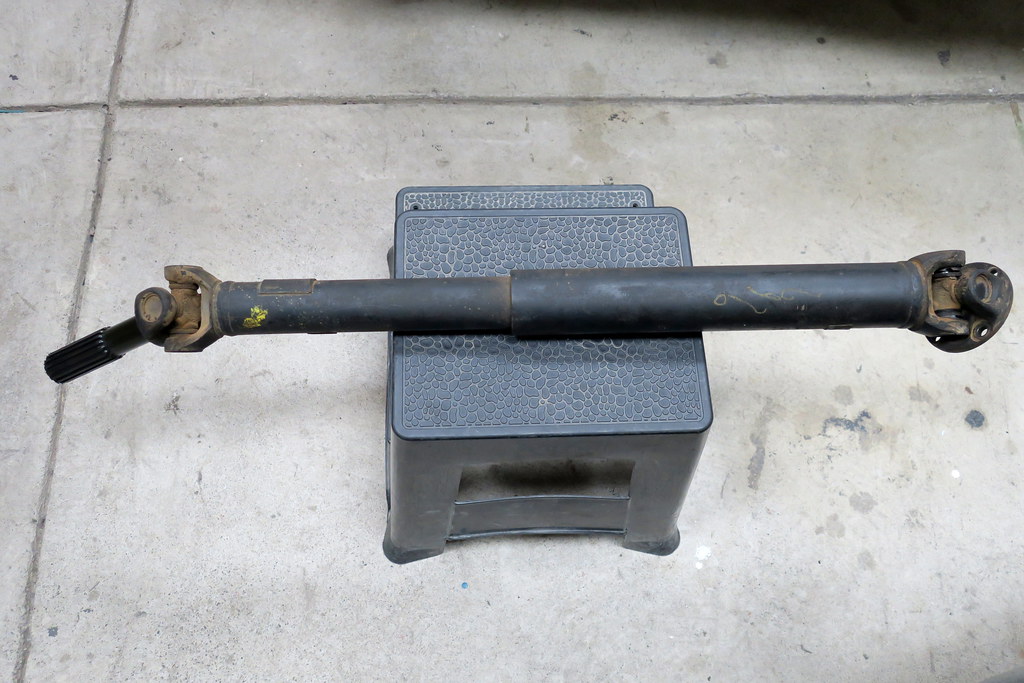

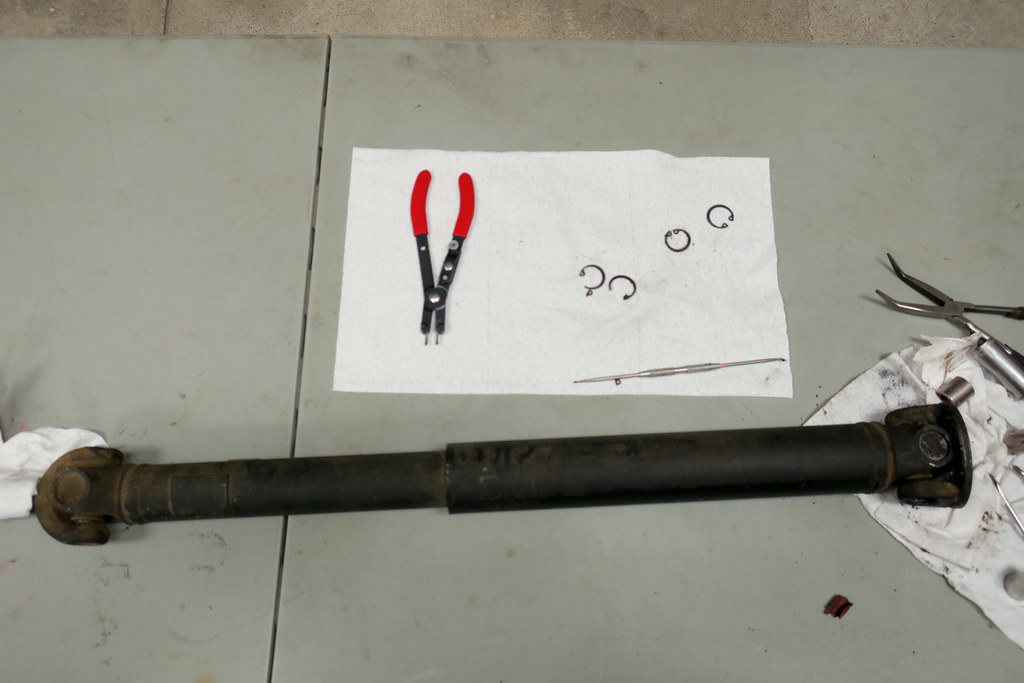

There have been a few more issues in the last two months, such as one of the fuses blowing continually taking out the turn signals. First thinking the problem stemmed from the turn signal stalk or a ground, eventually with pinpointed the issue to a short in the wiring to the reverse switch in the transmission. In mid-December took the 242 on a vintage car day drive through the East Bay, (about 200 miles) and now a clunk seems to be originating in/near the driveshaft. Need to figure out the origin is a bad u-joint or something else around the differential or rear suspension.

This brings things up-to-date with work and progress on the 242 build. It definitely took longer and more work than anticipated, but then again that can be said about most projects. I wanted to make these posts comprehensive and detailed around the work involved. (FWIW, the word count on this tread tallies up over 11K words in total.) It would be interesting to hear feedback, comments or questions on this write-up and what is helpful or needs further detail.

Since making the 242 operational, overall work and progress slowed down comparatively in the subsequent months. Since the CEL light still mocked me from the instrument cluster, I unplugged the ECU to clear the codes and see how long it took to return. Driving the car for a couple minutes it came back on with the familiar codes of 2-2-1 and 2-3-1. For the next couple of weeks the car did not like starting cold as it would stumble and hesitate especially when going up hills or hard acceleration. Searching and consulting the internet did not turn up anything conclusive. One morning decided to remove the spark plugs to inspect them and see if they show evidence of running lean or rich. Looking at them they were definitely not fouled, but more on the lean-ish side of the spectrum.

Reinstalling the plugs back in I restarted the car and suddenly it idled smoother than it had in a while. After pondering what had just happened, the proverbial lightbulb went off. I realized one of the components I had not changed out this whole time were the ignition wires. Being a set of Bougicords wires, had not thought they would be suspect or needed to be replaced out. Later that afternoon ordered a new set of Bougicords along with a few other parts. Arriving just before July 4th, installed the new wires which resolved the running issue and the CEL light illuminating.

One of the other plans for the 242 involved installing a set of 242GT driving lights and grill. I had all the parts to make the conversion, but I did not know the exact location of where to drill holes for the mounts into the valence. After posing a question on Turbobricks, Highperauto posted with a link to the installation instructions online and two days later the driving lights had been installed and wired up.

http://www.turbobricks.com/forums/showthread.php?p=5431175

In August dug into the front suspension noise. Talking the front wheels off and looking around I checked out the various components. On the passengers’s side while looking at the front strut, noticed the several threads were visible on the strut retaining collar. Using a pair of large channel locks, grabbed the sides and tightened down the collar into the strut tube and the noise disappeared.

During the same period the overdrive started to be contemptuous. It began not able to engage and every so often would work, but most of the time would not. Started by checking the wiring going through the shifter to the push button in the knob, but that looked to be not the issue. After thinking back to the other electronics which failed (ECU and Fuel Injection relay) when trying to initially start the car, dug through the spares to locate another relay. Swapped in a new replacement and the OD now worked on demand. The wet spring and garage environment really did a number on the car.

Added a creature comfort in the form of an armrest between the front seats, the type with the integrated cup holders found in the later 240s. Found one in the junkyard several years back and finally installed it into the car. Since the 1975 does not have the pre-drilled holes in the transmission tunnel, had to use that type instead of the more common rectangular armrest.

There have been a few more issues in the last two months, such as one of the fuses blowing continually taking out the turn signals. First thinking the problem stemmed from the turn signal stalk or a ground, eventually with pinpointed the issue to a short in the wiring to the reverse switch in the transmission. In mid-December took the 242 on a vintage car day drive through the East Bay, (about 200 miles) and now a clunk seems to be originating in/near the driveshaft. Need to figure out the origin is a bad u-joint or something else around the differential or rear suspension.

This brings things up-to-date with work and progress on the 242 build. It definitely took longer and more work than anticipated, but then again that can be said about most projects. I wanted to make these posts comprehensive and detailed around the work involved. (FWIW, the word count on this tread tallies up over 11K words in total.) It would be interesting to hear feedback, comments or questions on this write-up and what is helpful or needs further detail.

Last edited: