mopar318

Well-known member

- Joined

- Apr 8, 2013

- Location

- Fort Wayne

Had a slight oversight with the original bracket...that why I make one out of cheap/free wood first.

Other than some clearance I had to make the bracket fits perfectly.

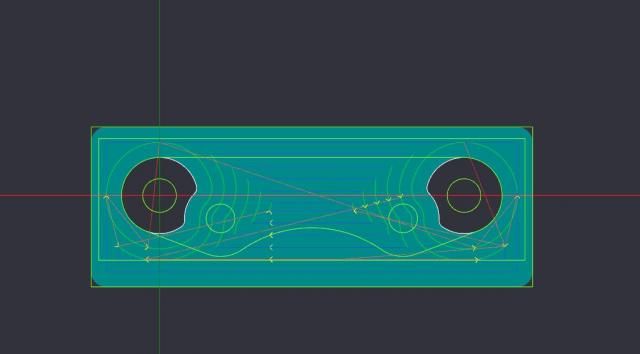

All ready to cut on Friday. I ordered a corner radius end mill so it will look a little better and reduce any sharp corners.

Inner rectangle is the actual size of the stock. Outer is a imaginary element added so i can pocket all of the stock out, then flip it over to mill off what is clamped in the vice.

Other than some clearance I had to make the bracket fits perfectly.

All ready to cut on Friday. I ordered a corner radius end mill so it will look a little better and reduce any sharp corners.

Inner rectangle is the actual size of the stock. Outer is a imaginary element added so i can pocket all of the stock out, then flip it over to mill off what is clamped in the vice.