Powder>Paint

New member

- Joined

- Jan 31, 2017

- Location

- Bay Area CA

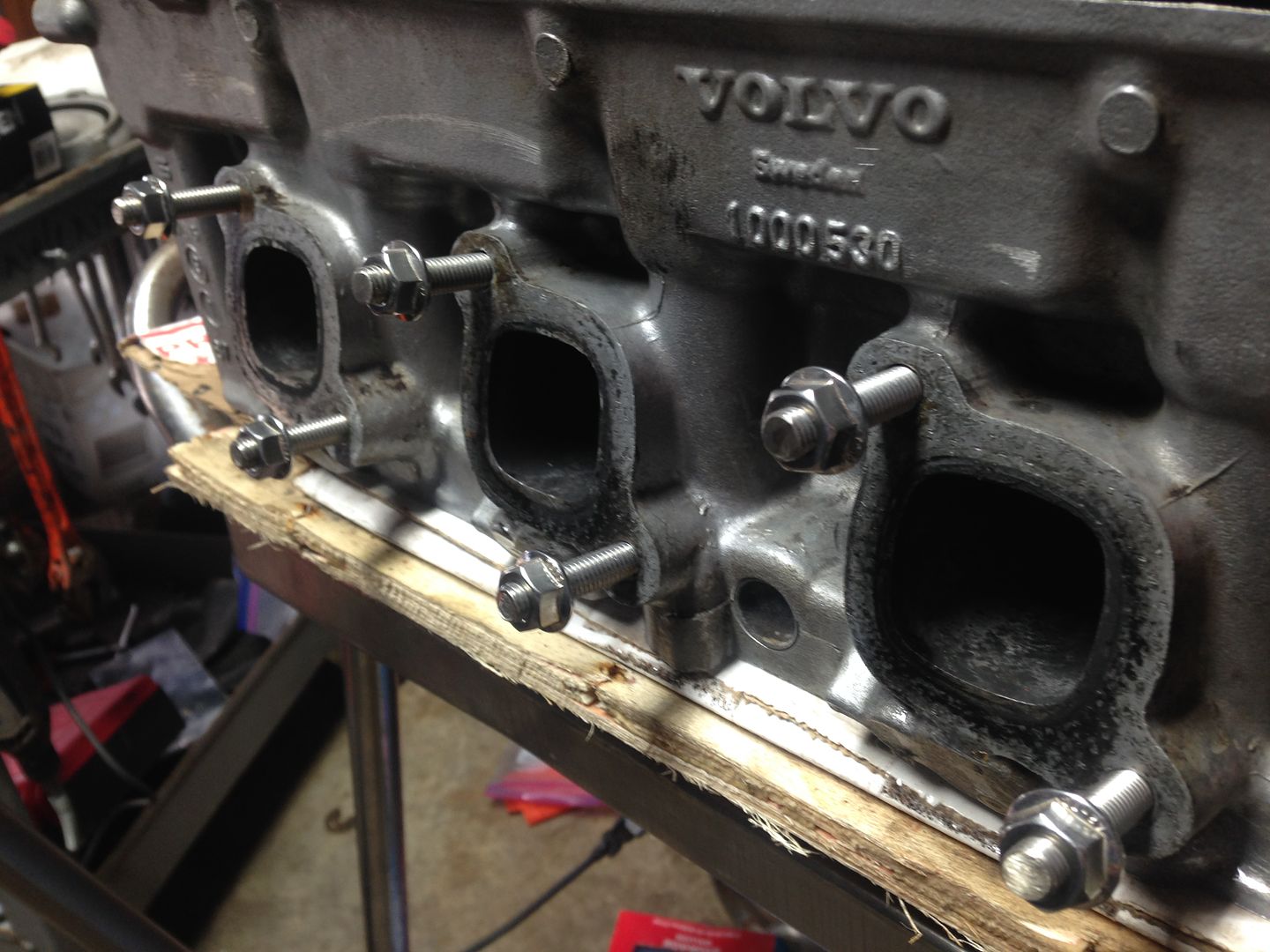

So after 450k, the exh mani studs in my 8v head are looking rough off. missing threads, stripped head threads etc. The replacement studs at napa are def dildos, the metallurgy just cant hang in this app, ive tried. Im at the point of replacing all the studs, and i wanted to see if anyone had done a stainless steel stud kit, based on longevity and hardness of fasteners. If so, experiences? pics? price? it seems like the studs in stainless are like 3-5 bucks each, so i want it to be a permanent fix if i do it. To be frank id like to replace every bolt on the motor w stainless, but thats casue i like shiny.

this is what im looking at, or something equivalent, allen head not required.

http://www.ebay.com/itm/9-Piece-M8-...ash=item35f276b6c3:g:BJcAAOSwiLdWBg9N&vxp=mtr

this is what im looking at, or something equivalent, allen head not required.

http://www.ebay.com/itm/9-Piece-M8-...ash=item35f276b6c3:g:BJcAAOSwiLdWBg9N&vxp=mtr