496truck

New member

- Joined

- Jan 16, 2012

- Location

- Carver, Ma

Has anyone done this before? Am I crazy? Or just doing it wrong?

As a homeowner and a dad I can find a million other places to spend the dollars it takes to buy an adjustable timing gear, new or used. Even the "affordable" incrementally adjustable gear from IPD is almost $100.

After installing my RSI stage 1 cam I was slightly sad at the loss of low end torque, where most everyday street driving is needed. But loved how that cam pulled in the upper RPM range. Not very often, with an auto trans anyway, do you get the chance to pull those RPMs. At least not here in overcrowded New England. After a bit of research I had read that most users gained a bit of low end torque back by advancing the cam about 4*.

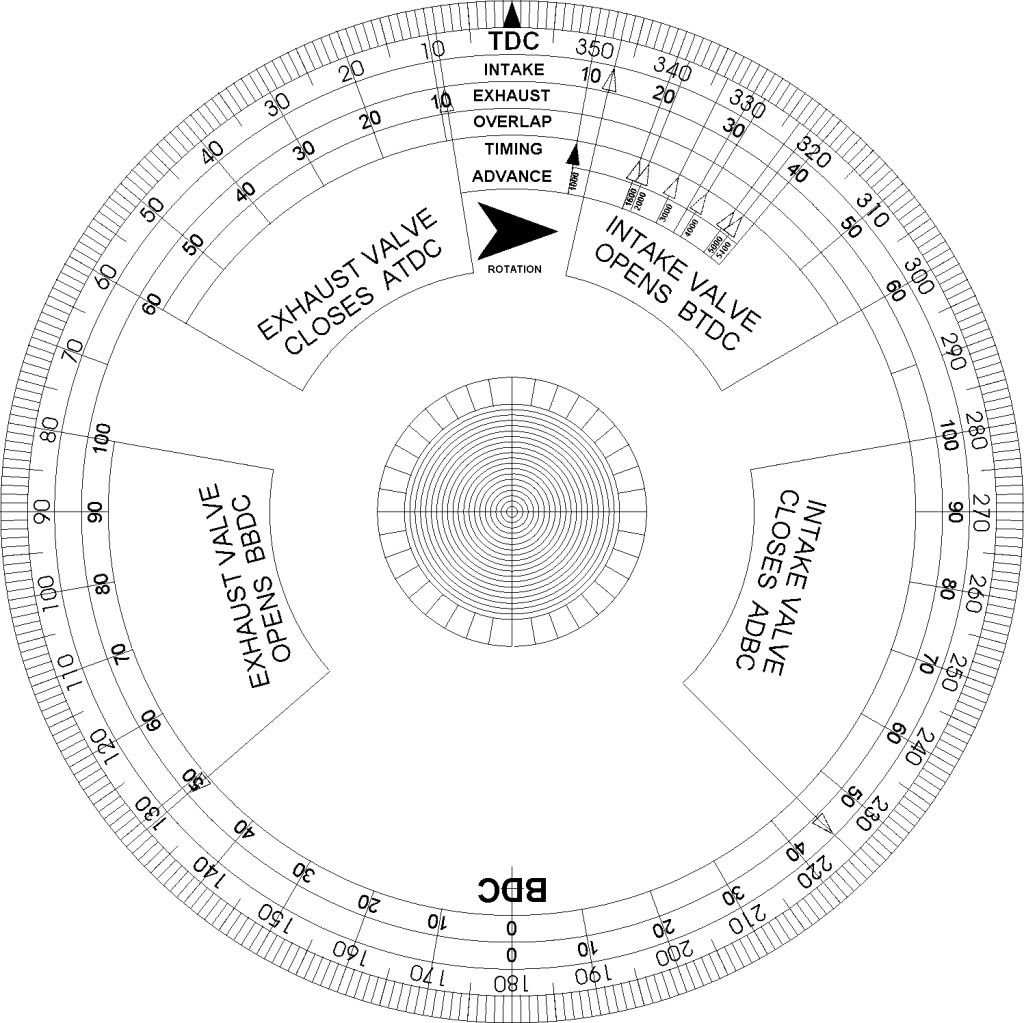

I had an extra cam gear lying around. Advancing the cam gear 1 belt notch is about 10* (well, according to my count and math it was 9.something close enough to 10), which is more than I was looking for. So, why not make a timing mark 180* off and drill a new hole for the cam gear locating pin? I made some marks 1/2 a tooth forward, scribed some lines on it, center punched it and drilled a new hole. At this point I have about a 4-5* advanced gear.

I plan on swapping this in Wednesday unless someone has a good reason for me not to. Will add pics too.

As a homeowner and a dad I can find a million other places to spend the dollars it takes to buy an adjustable timing gear, new or used. Even the "affordable" incrementally adjustable gear from IPD is almost $100.

After installing my RSI stage 1 cam I was slightly sad at the loss of low end torque, where most everyday street driving is needed. But loved how that cam pulled in the upper RPM range. Not very often, with an auto trans anyway, do you get the chance to pull those RPMs. At least not here in overcrowded New England. After a bit of research I had read that most users gained a bit of low end torque back by advancing the cam about 4*.

I had an extra cam gear lying around. Advancing the cam gear 1 belt notch is about 10* (well, according to my count and math it was 9.something close enough to 10), which is more than I was looking for. So, why not make a timing mark 180* off and drill a new hole for the cam gear locating pin? I made some marks 1/2 a tooth forward, scribed some lines on it, center punched it and drilled a new hole. At this point I have about a 4-5* advanced gear.

I plan on swapping this in Wednesday unless someone has a good reason for me not to. Will add pics too.

![DSCF0005.JPG[iMG]](http://www.pbase.com/jaodesign/16v_adjustable_gear.jpg/DSCF0005.JPG[iMG])