496truck

New member

- Joined

- Jan 16, 2012

- Location

- Carver, Ma

B230FT Basic Build, Just need a runner at this point

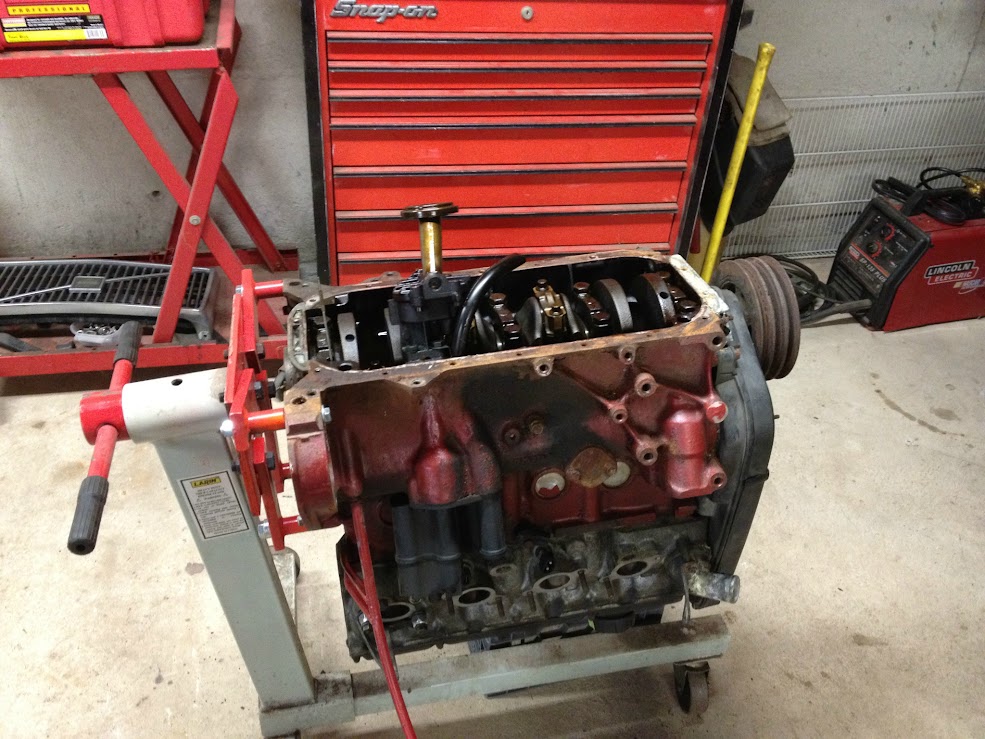

So, my old 745t's original engine has almost 200k on it and really sounds like a diesel at idle, especially when cold. Put the word out that I was looking for a replacement/rebuilder engine to one of my customers who deals specifically with old RWD Volvos. Says he has a rebuilt B230FT with about 20k miles on it, unsure of year but knows it's not a squirter block. Price was right (get it out of here, pay me when you can) so I took a chance on it.

Looks fairly clean for what I want to do. I plan on cleaning it up, paint, new hardware where needed.

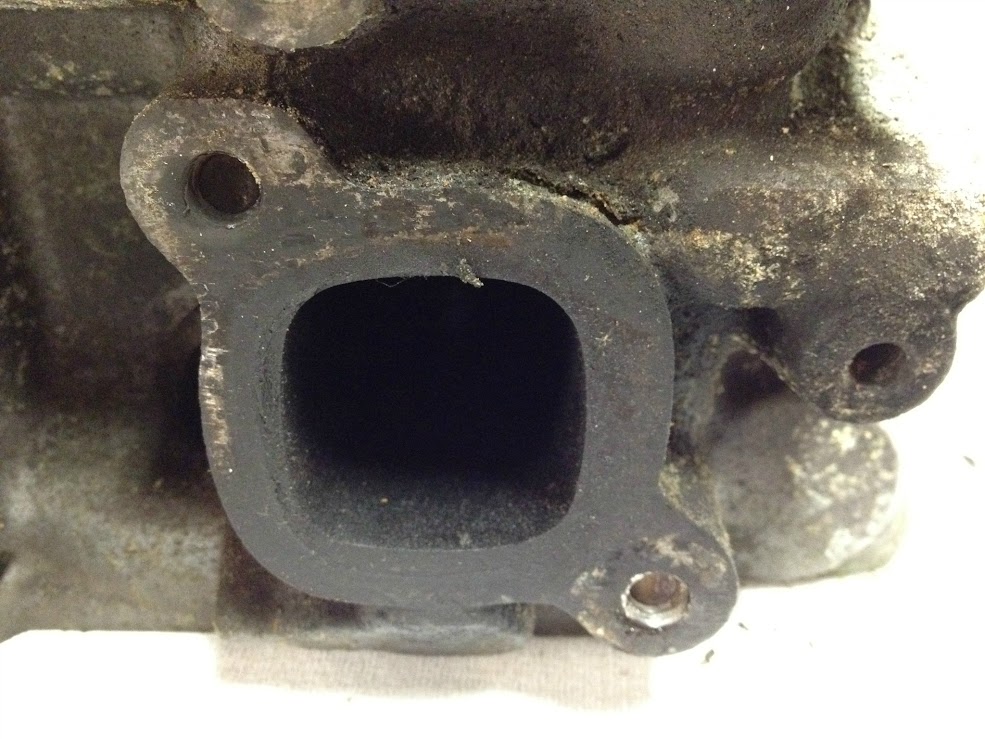

Cheesy freeze plug repair. I have a correct replacement for it.

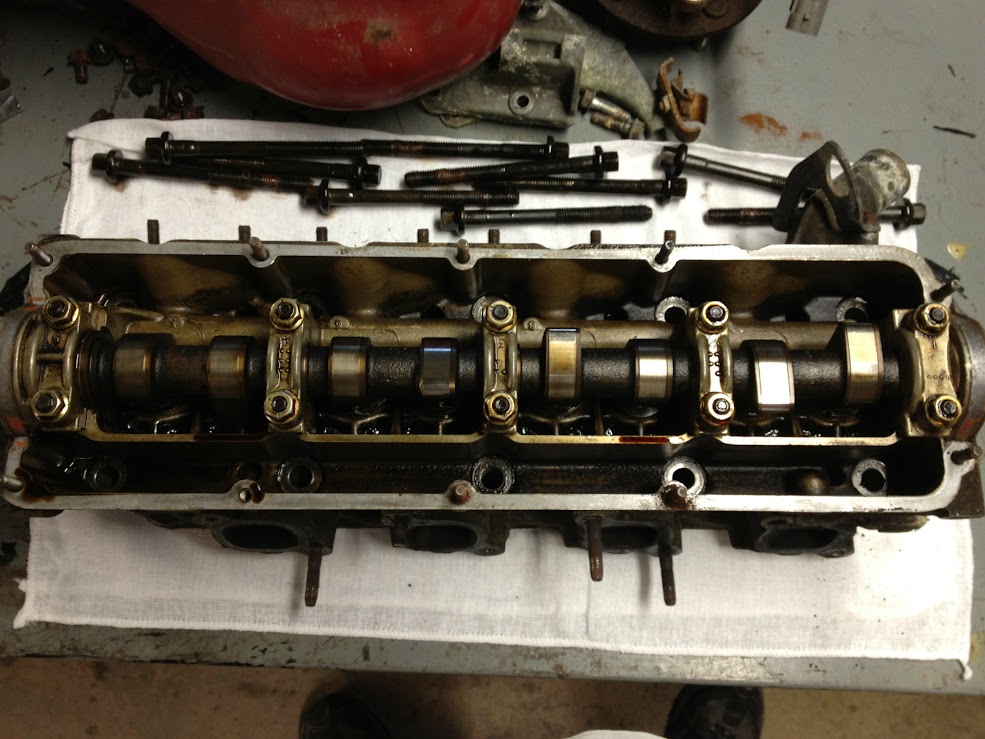

2 broken off exh mani studs in the head. Currently working on removing the rest with heat and PB Blaster. Open to suggestions on these 2 suckers though.

Standard issue 530 head with T cam.

Cylinder walls look OK, no ridge at the top just crud.

Ooooooh, that sucks.

Now, he did call me yesterday and said he had an NA squirter short block that was going in the scrap pile. Do the later NA engines use the thicker rods? And are they a straight up replacement for the Turbo rods? If I can just go get the rods from the short block and swap them onto these pistons that would make this a whole lot easier to deal with.

So, my old 745t's original engine has almost 200k on it and really sounds like a diesel at idle, especially when cold. Put the word out that I was looking for a replacement/rebuilder engine to one of my customers who deals specifically with old RWD Volvos. Says he has a rebuilt B230FT with about 20k miles on it, unsure of year but knows it's not a squirter block. Price was right (get it out of here, pay me when you can) so I took a chance on it.

Looks fairly clean for what I want to do. I plan on cleaning it up, paint, new hardware where needed.

Cheesy freeze plug repair. I have a correct replacement for it.

2 broken off exh mani studs in the head. Currently working on removing the rest with heat and PB Blaster. Open to suggestions on these 2 suckers though.

Standard issue 530 head with T cam.

Cylinder walls look OK, no ridge at the top just crud.

Ooooooh, that sucks.

Now, he did call me yesterday and said he had an NA squirter short block that was going in the scrap pile. Do the later NA engines use the thicker rods? And are they a straight up replacement for the Turbo rods? If I can just go get the rods from the short block and swap them onto these pistons that would make this a whole lot easier to deal with.

Last edited: